Leading Edge Erosion Causes MAJOR Problems

For Wind Farm Operators.

More and more wind turbines are being shut down to allow for leading edge erosion repairs.

Teams of technicians will spend significant hours up on ropes restoring the efficiency of these damaged blades.

$3000 per Day For Blade Techs?

Leading Edge Repair & Downtime is Expensive.

Already repairing leading edge erosion? Maximize your spend.

How Can You Maximize The Money Already Being Spent on Repairs?

Having wind turbine blade technicians on site is expensive - costing $3000+ per day, for jobs that can take weeks or months to complete.

What if there were other, easy repairs and upgrades to perform at the same time, to stretch the money you're already spending to repair leading edge erosion?

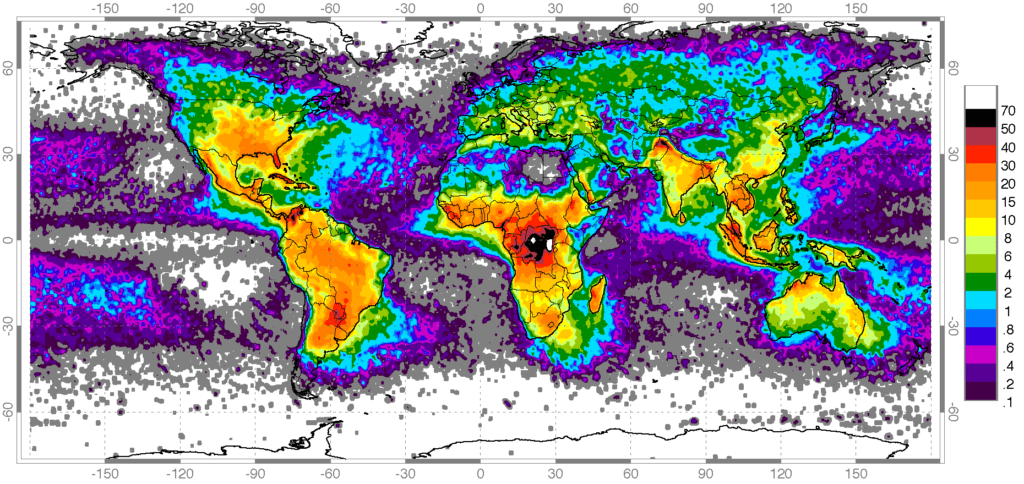

Millions of Daily Lightning Strikes

Means Significant Risk to Wind Farms

A map of lightning strike density around the world

8 Million Lightning Strikes Occur

Each Day All Around the World

With 100m+ rotor diameters, wind turbines are very attractive to lightning.

StrikeTape wind turbine lightning diverter strips are critical for wind farms to prevent damage & downtime.

Solve Leading Edge Erosion & Lightning Problems at the Same Time

Download Specs on Our Easy LPS Upgrade

Lightning Damage Requires More On-Site Repairs

Yet, It's Easy to Prevent.

Your Techs Are Already Up on Ropes.

A Quick LPS Retrofit Can Prevent This Damage

StrikeTape is ISO Certified - Quality You Can Trust

Frequently Asked Questions

StrikeTape features more durable materials, gold plating for superior conductivity, and advanced engineering to pass regulatory testing with ease.

Yes – StrikeTape is flexible and will conform to the shape of any turbine blade.

Yes – with the adhesive backing, it’s no problem removing and repositioning StrikeTape before edge sealant has been applied.

Even in the most extreme weather conditions–cold, rain, high altitude, roaring winds–StrikeTape will typically provide 4-5 years of trouble free service.

Yes. If you know your StrikeTape style, you can easily re-order via our quote form on this page.

Call us! We have StrikeTape for every turbine application, and we’ll make sure you get the exact part number you need.

No! Our proprietary edge sealant provides virtually zero impact on the blades natural aerodynamics.

More Questions?

Ready to Start?

Our Wind Turbine LPS Retrofit is

Proven to Significantly Reduce

Blade Damage & Downtime

Withstand repeated high-energy lightning strikes for years of trouble-free service

Installation? Takes Just 20 Minutes.

STEP 1

Clean the Surface

Step one: prep the wind turbine. We'll guide you through it in our videos.

STEP 2

Peel & Stick

Applying StrikeTape is simple: peel off the adhesive backing and apply.

STEP 3

Apply Edge Sealant

Proprietary edge sealants finish the job. Get fast curing and no oven time.

Our LPS is Protecting Wind Farms Worldwide

JAPAN

INDIA

DENMARK

UNITED STATES

CANADA

ITALY

BRAZIL

UNITED KINGDOM

Upgrading Your LPS at the Same Time

As Your Leading Edge Repair?

It Just Makes Financial Sense.

Requires No Blade Modifications

Resistant to Rain Erosion

Easy to Install

Follow our quick guide below for StrikeTape wind turbine lightning diverter strips

We Walk Your Techs Through Installation