As wind turbines age, their annual energy production decreases, and while the decrease is slight – generally accepted at about 2% per year – it can significantly extend the return on investment (ROI) period for owners. It’s important to note that even though the decrease in power is attributed to “aging,” it starts almost immediately after the turbine is installed. This is why wind turbine power curve upgrades can be so critical for long term performance (and profits).

While power decreases are typical of various types of machinery, wind farm operators have technology on their side. Thanks to global studies and research collaborations, many wind turbine blade retrofit options are available to help recover lost efficiency and even improve production.

Questions to ask about power upgrades before you retrofit your blades

Retrofitting Wind Turbines for Longer Life, More Power

Numerous companies, including Polytech, Siemans Gamesa, Vestas, Smart Blade and others, offer Power Curve Upgrades (sometimes called PCUs or just power upgrades) and other retrofits to improve annual energy production (AEP). The good news is they work. The bad news is there are a lot of variables in every site, and retrofit methodology varies. In other words, selecting the best retrofits for your particular location requires considerable review and investment. Michael Johansen from Anemo Analytics shared great insight on performance optimization of wind turbines on our podcast.

While we’re not experts in blade upgrades, we are experts in lightning behavior, and in that capacity, we work closely with wind operators who use DinoTails, vortex generators, winglets and sometimes a combination of retrofits and power upgrades to maintain or improve their AEP. Although any wind turbine bland modification or retrofit is likely to increase your equipment’s risks related to lightning activity, there are ways to mitigate those risks and improve your lightning protection system (LPS).

For the latest insight into lightning behavior and other turbine-related news, subscribe to the Uptime podcast.

Wind Turbine Blade Retrofits: Dino Tails, Vortexes and Winglets

Improving Aerodynamics to Increase Energy Production

DinoTails, Vortex generators, and winglets are some of the most common PCU options available to turbine owners.

While the ultimate goal of retrofit products is to increase output (and profits), they all work a bit differently. Some increase power production increasing lift and reducing drag, others focus on reducing turbine noise. (Why? Decreasing noise allows operators to increase speed and therefore, energy output, while remaining within noise regulations.)

Altering the aerodynamics of a wind turbine blade can affect lightning paths, and most additive modifications to blades affect potential strike path locations. One reason: the modifications may create areas that accumulate debris and dust.

Trailing edge blade modifications can improve power production, but they also carry increased risk of lightning damage.

DinoTails

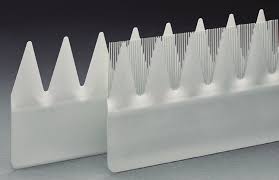

Siemens Gamesa’s DinoTails has become one of the most familiar retrofit designs. Having serrated edges glued onto the trailing edge of the blade tip increases lift and provides noise reduction. This allows turbine operators to increase the speed of the blades without exceeding noise level regulations and therefore, to increase power production.

The added fine “combs” between the original design’s serrated edges further reduces noise by generating small flow structures. They are also proven effective at increasing power – the manufacturer’s disclosures show the range of improvement of 1-3% in additional power production. Unfortunately, those combs can also harbor dust which can hold a static charge.

The similar-sounding DinoShells are intended to increase lift and blade productivity, however, DinoShells, which are mounted onto the trailing edge of the blade root, do not extend the blade’s original length. Like DinoTails, they’ve been around for nearly a decade, and they too offer a proven power boost.

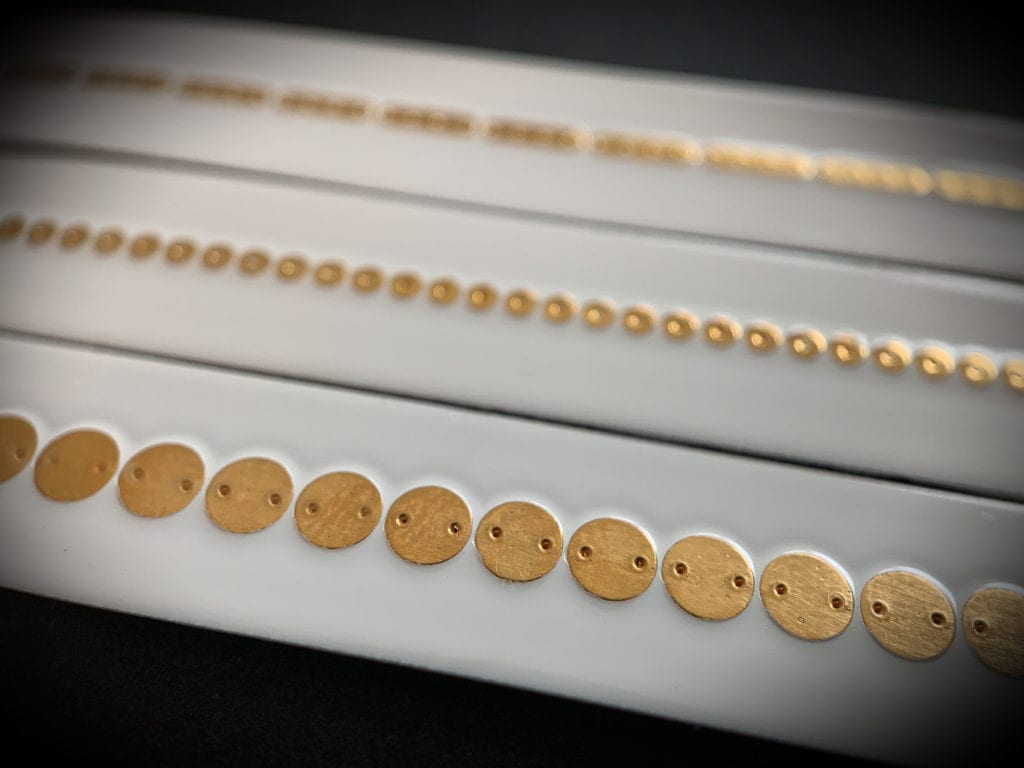

Vortex Generators

Vortex generators are fins mounted to the root section of the blade and the outboard tip. They improve lift by reducing flow separation over the blade, creating controlled flows that stay along the blade surface. The result is more torque turning the rotor, and therefore, greater energy production.

The downside? Again, anything that alters air flow, however locally, can and will alter lightning behavior.

Winglets

Attached to the tip of the turbine blade, winglets are designed to reduce the drag caused at the blade tip. Thickness, cant angle, and other winglet geometry can significantly alter performance.

Because winglets tend to increase structural loads, some have questioned the economic feasibility of winglets. However, a 2019 computational simulation showing that winglets could offer a 4.39% improvement in the coefficient of power is likely to encourage continued use of winglets and more studies to continue to improve designs and performance.

For more information on the computational fluid dynamics at work, see the article in Advances in Mechanical Engineering.

How Blade Modifications Affect A Wind Turbine LPS

How do different type of blade retrofits affect wind turbine lightning protection systems (LPS), including downward lightning, upward lightning, and overall strike potential?

The good news is that as more research showing how lightning behavior is altered in the presence of various blade modifications becomes available, the better the corresponding turbine blade LPS modifications are at reducing your potential damage. Your goal is to get the best available solution to protect your turbines.

We know that changing the air flow structure affects both downward and upward lightning. While each site has a unique set of variables, based on our work with both equipment owners and manufacturers, we understand how to effectively mitigate damage.

Questions to Ask Before Installing Turbine Blade Retrofits

Will power upgrades change the amount of lightning strikes? Probably.

Depending on the materials used and the projection, you should expect increased incidence of up-lightning. While it’s not as dramatic as down lightning, even small strikes or “leaders” have proven damaging

Will it change location of lightning strikes on the blade? Most likely.

Lightning strikes will vary depending on design/changes to the leading edge, trailing edge, or root, because it will affect air flow, and any change to air flow impacts lightning activity. The good news is we can predict those changes more accurately than ever, and design to counter the effects.

Do wind turbine blade retrofits require modification or upgrade of an LPS?

Yes, absolutely. Anything that even slightly alters the profile or performance of a blade is a material change that should cause owners to re-assess risks in terms of lightning damage. It is hard to calculate, but upgrading your wind turbine LPS be considered in upfront cost estimates. Either factor in additional lightning protection, or anticipate that you will likely experience more damage in the future.

How will this location change affect wind turbine blade damage – or the bottom line?

Because of the likelihood of increased lightning strikes, it’s highly probable that some of the gains the retrofits are designed to deliver will be lost due to minor damage to the blade, either from increased tracers or very small strikes, or due to outright failures that require repairs and extensive downtime.

Wind Turbine LPS Recommendations for Technicians and Owners

When considering blade modifications, it’s critical to reevaluate your LPS. As clearly as research shows that winglets, vortex generators, DinoTails and other retrofits can improve wind energy output, it’s also shown that lightning behavior changes as the power curves and air flow changes – and no factory-installed lightning protection is designed to manage it. Further, many existing LPS strips are not robust enough to protect your equipment through normal weather erosion.

See Strike Tape specifications

Any lightning activity, even very small strikes, will add up to damage and therefore decreased power production – at best. At worst, that lightning can result in significant damage and downtime. The more damage, the longer the ROI period, and the slimmer the operation’s profit margin.

For those reasons, most wind turbine blade technicians recommend installing lightning protection upgrades whenever a retrofit is planned. Because dust is a lightning magnet, those LPS considerations will focus largely on where and how dust can settle on any retrofits.

Bottom Line Considerations

Wind turbine blade retrofits have proven effective in increasing power production (more than offsetting the expected decrease of about 2%/year), but they also require a significant investment. The equipment itself is only a small part of the total investment, which includes labor as well as necessary downtime for installation.

The bottom line is, how much do they cost? The answer depends on numerous factors, but for estimating purposes, in addition to hardware and design costs, wind farm operators need to factor in installation costs, which for general purposes is likely to require 2-3 technicians for roughly one day per blade, plus associated downtime and lost production.

Operations and accounting departments need to carefully consider the cost as well as timing of retrofit installations, as each site location is different, and other considerations (like age of equipment) affect the anticipated payback period. Remember, manufacturers’ estimated life expectancy and durability is calculated under ‘normal’ conditions – and lightning damage is rarely factored in.

Our Goal is the Same as Yours: Increasing Productivity, Extending Life of Wind Turbines

Since the point of any power upgrade is to improve output and extend the turbine’s operational lifetime, it just makes sense to protect that kind of investment.

If you’re considering an upgrades or retrofits, you want to ensure more uptime and protect against potential damage. To make sure you understand how planned upgrades may change the lightning paths on your blades or towers, contact us.

“You can predict what the outside world looks like mechanically, but you never really know till you get out there and you watch how some of the failures are occurring.” –Uptime Episode 24, on turbine simulations and lightning behavior

Adding retrofits to increase AEP? Don’t forget your LPS!

More Wind Turbine Power Curve Research and Resources

In their 2018 paper, The Science of Making Torque from Wind, authors from the Technical University of Denmark, Lyngby Campus, analyzed winglets and sweep on wind turbine blades, but their study did not consider potential changes in lightning paths.

A 2016 study of winglets for wind turbines focused on three different construction methods and how they affected economic feasibility.

- We discussed DinoTails and other retrofits, patent infringement questions, and testing in a recent Uptime podcast episode. Tune in here.

- Adding retrofits to increase AEP? Don’t forget your LPS! Upgrading your system today is quicker and easier than you might think – and we can help in the decision-making, design, and installation process.