Keeping up with technology and business demands is a challenge in any industry; that goes double (at least) in wind and sustainable energy business. Below, we note some of the top trends we’ve seen in 2021 that we expect to follow in 2022. In the trend descriptions below, we’ve linked to interviews with wind industry experts so you can hear their insight and what they see for the future of the technology and the business.

If you’re in the industry, we’d love to connect here, on our YouTube channel or other social platform. We need to learn from each other in this fast-moving industry!

Get the latest wind turbine business and tech news delivered to your in-box

Wind Industry Trends, 2021-2022

Wind Turbine Blades Get Bigger, Profits Not So Much

As wind turbine blades get bigger, they produce more power. They also get more expensive. This has had several effects in the industry. Maintenance of existing turbines is more important than ever, and retrofits to maximize annual energy production (AEP) comprises a fast-growing segment of the industry. Retrofits like vortex generators, winglets, and power curve upgrades (PCUs) can help bolster AEP and increase the profitable life of blades and wind farm operations.

World’s Tallest Turbine? It’s a moving target.

Just how fast are blade lengths growing? In March, we were talking about Siemens Gamesa Renewable Energy B108 blades. At that time, at 108 meters long, they were the largest ever produced. Six months later, Vestas announced its V236- 15MW turbines – at 280 meters tall, and blades more than 115 meters long – would be generating electricity in Denmark by the end of 2022.

Since bigger blades mean bigger risks, and because the wind industry has always operated on slim margins, it’s only logical that wind turbine blade maintenance would become more important.

Maintaining wind turbine blades means more energy, more uptime, and more profits. Of course, while wind turbine maintenance should be on a regular schedule, those tasks are hardly routine, or simple – especially for mere humans. Enter the robots.

See simple wind turbine blade maintenance tips here.

More Robots Working in Wind Industry Maintenance (and More People are Needed)

“Leading edge erosion is pretty much 50% of the whole market of blade maintenance at the moment,” Rope Robotics CEO & Co-Founder Martin Huus Bjerge said earlier this year. And robots can be very good at things that put people at risk – like inspecting and repairing blades.

Saying that wind turbine cleaning robots and drone inspection companies are busy could qualify as one of the biggest understatements of 2021. More robots working in the industry, however, does not mean fewer people are needed – quite the opposite. And that’s one trend we’re sure will continue.

Yes, smart robots are popping up on blades everywhere, but they’re not taking jobs from anyone…in fact, if you want a good job, the wind industry is a great place to work.

See the Wind Turbine Technician Salary and Job Outlook here

Wind Power Lab’s Morten Handberg spoke with us about the need for people and “creative preventative maintenance plans.”

We also spoke with the CEO of Ping, a company that “listens” for blade damage. In both interviews we learned how common damage is, and how easy it is to overlook “minor” damage that can cause significant drops in production.

The good news: there are more options to repair the damage and to extend the life of those blades. The bad news: turbine blade repair and maintenance companies are really busy. Better book your technicians – and their robots – now.

More Offshore Wind Projects, With More Unknowns

Offshore wind turbine costs are difficult to calculate because the infrastructure to create offshore wind farms really doesn’t exist yet. Practical matters like developing wind turbine technician training programs that address the specific challenges of offshore projects are still on the drawing board.

States differ in their approach to US offshore wind projects and regulations. Now that the initial excitement over COP 26 has died down, it’s time to find out how ready the world really is for offshore wind farms.

How Green Will Energy be in 2022? We talk to experts in the wind industry every week. Tune in.

From a science and engineering standpoint, we’re still learning how offshore lightning behavior is different from lightning behavior on land.

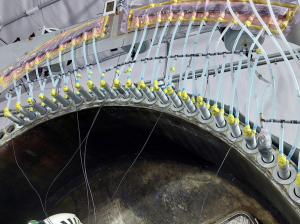

The industry has begun to understand that to be effective, lightning protection needs to be highly site-specific. Some blade manufacturers are even modifying their factory packages and protection options. Weather Guard engineers are involved in several large-scale, onshore tests going on now that illustrate the unique lightning environment of each wind farm must be considered, and lightning protection modified for maximum protection. Offshore data is available, but taking that into account when designing floating energy farms is a significant task. The size and scope of projects is an indication that we’re committed to solving these projects – but how soon we will have solutions is (yet another) unknown.

Is an onshore wind revitalization overdue?

While the massive investments in US offshore wind projects have gotten a lot of news coverage, we wouldn’t be surprised to see increasing interest in repowering existing windfarms. In May, Vitol announced plans to upgrade Big Sky Wind Farm in Illinois. Excitement over offshore is justified, but we’ve hardly begun to tap (onshore) production capabilities. And, onshore wind operations look easy when compared with offshore production. For one thing, onshore wind farms don’t have to worry about upsetting the fishing industry. (OK, that’s not all. But onshore is less complicated than offshore.)

The Insurance Industry is Getting Interested in Wind

Lightning protection for wind turbines is just one of the factors that’s getting more attention from the insurance industry. We expect liability issues to become a hot topic in 2022 and 2023 in the US wind industry (and worldwide).

Between increasing cybersecurity risks, bigger expenditures for bigger blades, and more unknowns (offshore siting issues, wind/lightning behavior, and others), legal issues and land rights battles, insurers are getting involved.

Way back in 2020, we talked to DNV GL engineers about the difficulties wind farm operators face when all lightning damage is classified as force majeure. Will that change in 2022? Stay tuned…we are!

Collaboration Is Key

Sharing knowledge, including metrics and measurements, is critical to continuing advancements in the highly technical wind energy business. Weather, and wind, and policies vary around the world, affecting AEP on each wind farm just a little bit differently. Sharing what we know about our common problems and of course, solutions, is good for everyone in the business.

Producing the Uptime Wind Energy Podcast has given us access to some of the brightest, busiest people in the wind industry. In the beginning, we expected the podcast to focus on the technical advances and challenges in the industry, with a special focus on improving lightning protection for wind turbines. It was apparent immediately that those experts want to share myriad engineering challenges – and solutions! – with the wind energy community. So, every week, we connect with wind energy experts, engineers, technicians, and planners around the world to discuss wind turbines and everything that affects them.

We’re thrilled to have had so many great guests join us on the Uptime podcast. We offer a hearty thank you to each and every one. You are welcome back anytime!

We look forward to a great new year, and a chance to learn from and work with more of the best and brightest in the industry.

Sharing What We Know

We commissioned Power Curve to assess the aerodynamic impact of StrikeTape in use as wind turbine lightning protection for blades of all sizes. Engineers calculate a baseline annual energy production (AEP) using an industry-standard blade element momentum (BEM) model, followed by a computational fluid dynamics (CFD) simulation to assess the potential aerodynamic impact of StrikeTape on AEP. See the report here.

Uptime a “Must-Listen” Podcast

We were honored to learn that the Uptime Podcast was named one of the top podcasts in the industry.

Here are five of our favorite episodes of 2021:

- Recycling Wind Turbine Blades into Cement: It works YES, you can recycle wind turbine blades. Rather than burying blades in landfills, Veolia is working to solve the logistical problems of transportation with their shredding techniques and other innovations.

- BladeBUG: Wind Turbine Maintenance Robot You won’t believe what these robots can do! Blade Bug founder Chris Cieslak talks about his robots’ capabilities – and yes, they really are operated with an X-box controller.

- How Do Vortex Generators Work? Nicholas Gaudern from Power Curve explains how wind turbine blade aerodynamics can improve, even as blades age and wear down.

- Rope Robotics: Making Wind Turbine Blade Maintenance Safer, Fasters, and More Accessible Martin Huus Bjerge, CEO of Rope Robotics, shared his thoughts on wind technician jobs, autonomous repair, and collaboration within the industry. Starting at about 8:10, listen as Bjerge describes the three basic categories of robotic-assisted blade maintenance.

- Did Wind Turbines Fail Texas? Do Turbines Work in Cold Weather? (Spoiler alert: of course they do.) We break down what happened when that weird ice storm hit Texas turbines.