In the first quarter of 2021, Weather Guard commissioned independent wind energy consultants Power Curve to conduct an aerodynamic assessment of StrikeTape in use as a lightning protection system for wind turbine blades. Because StrikeTape is installed at the blade’s tip, and any change to the blades’ surface (including retrofits, dirt, or leading edge erosion) can result in aerodynamic performance change, the goal was to quantify what effect if any StrikeTape would have when used for lightning protection. The assessment used an industry-standard blade element momentum (BEM) model and conservative parameters. The StrikeTape lightning diverter was found to have no significant impact on AEP.

Industry Standard Models Used to Test StrikeTape

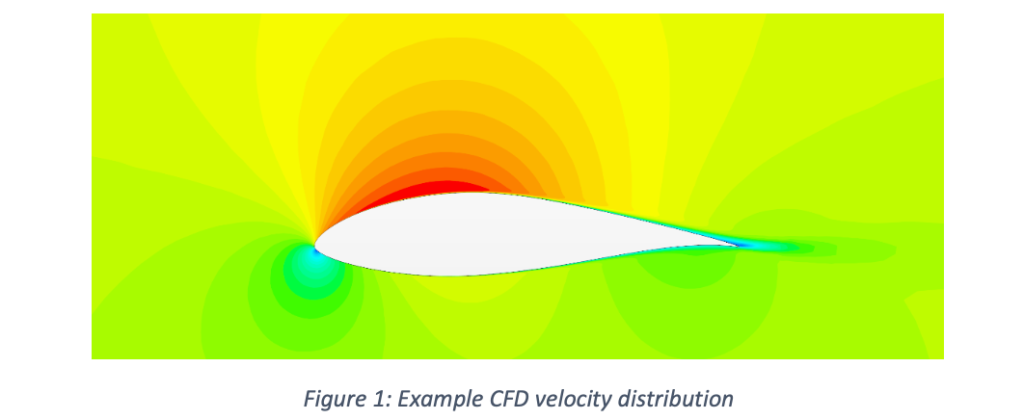

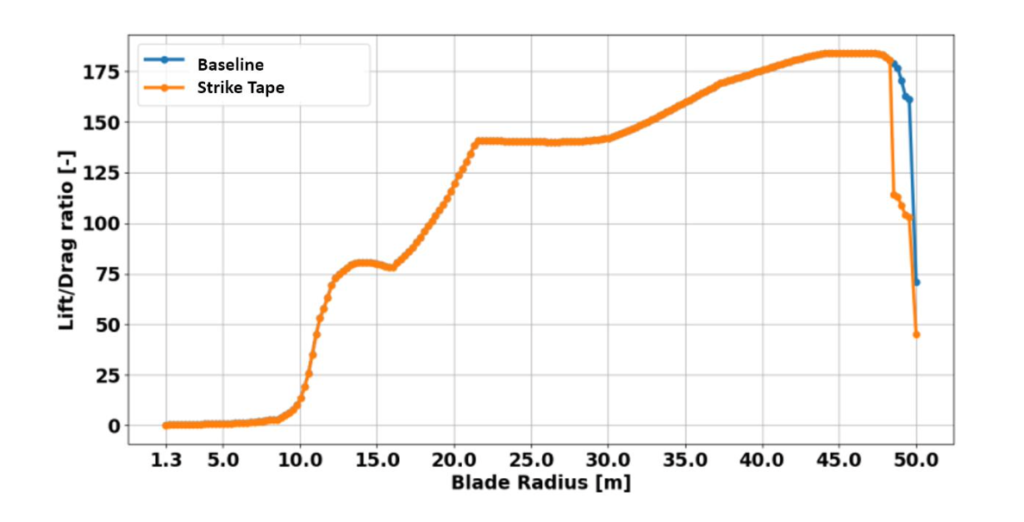

Engineers at the Denmark-based Power Curve created an industry-standard blade element momentum (BEM) model of the blades used on a GE1.6-100 wind turbine to calculate a baseline annual energy production (AEP). This was followed by a computational fluid dynamics simulation to assess StrikeTape aerodynamics and its potential impact on AEP. The CFD simulation was then carried out on the aerofoil used at the tip of the blade in two conditions: perfectly clean, and with premature transition resulting from StrikeTape.

In conclusion, the assessment authors stated, “StrikeTape has no significant impact on AEP and would be less than typical contamination or erosion impacts.”

For more information about the BEM model, testing, and results, download the assessment.

Download results of the assessment showing how the LPS affected AEP

AEP Impact of StrikeTape Lightning Diverter Strips: Testing Methods

In the tests conducted by Power Curve with StrikeTape lightning diverter strips on the GE wind turbine blades, potential AEP loss was found to be only 0.05%. For reference, leading edge erosion on the outer 1m of blade span would result in an AEP loss of at least 0.1-0.2%.

For testing purposes, slices were taken from a full blade model of the LM48.7, at thickness-to-chord ratio stations typically used for BEM modeling. Those slices were analyzed using a CFD approach to obtain lift and drag polars at relevant points. The blade geometry was combined with the aerodynamic data and pitch/curve estimates from publicly-available data.

The Power Curve-developed tests were conducted and results calculated with purposefully conservative parameters. Potential impact on AEP was calculated as if StrikeTape was installed on the outer 1m of the blade, for example, when in actual installations StrikeTape typically covers less than .5m of blade span.

Questions about the methods or AEP impact findings of StrikeTape lightning diverter strips? Contact us.

How a StrikeTape Lightning Protection System Can Affect AEP

In addition to cost, effectiveness and longevity, one concern when installing a lightning protection system for wind turbine blades is how it may affect performance.

Power Curve is uniquely qualified to conduct these tests, as the company specializes in performance upgrades for wind turbines. Nicholas Gaudern, Power Curve CTO, explains some of the company’s technology and methods in this Uptime podcast interview.

For more information about the most recent aerodynamic assessments of StrikeTape, download the study or contact us.

More Helpful Articles on Wind Turbine Maintenance

How Wind Turbine Power Curve Upgrades affect performance (and profits)

Leading Edge Erosion: Root Causes, Problems Presented, and Available Solutions