Can near lightning strikes damage wind turbines, even in the absence of a direct strike? The answer is yes – and damaged blades can mean downtime. As the air ionizes in a thunderstorm, high-voltage streamers and leaders can attach to a wind turbine. But are these near strikes on wind turbines very destructive? Read on as we discuss this phenomenon and how to protect wind turbines using segmented lightning diverter strips.

What Does a Segmented Lightning Diverter Do?

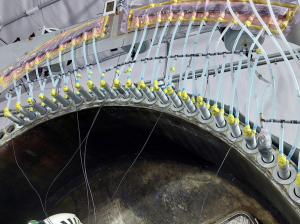

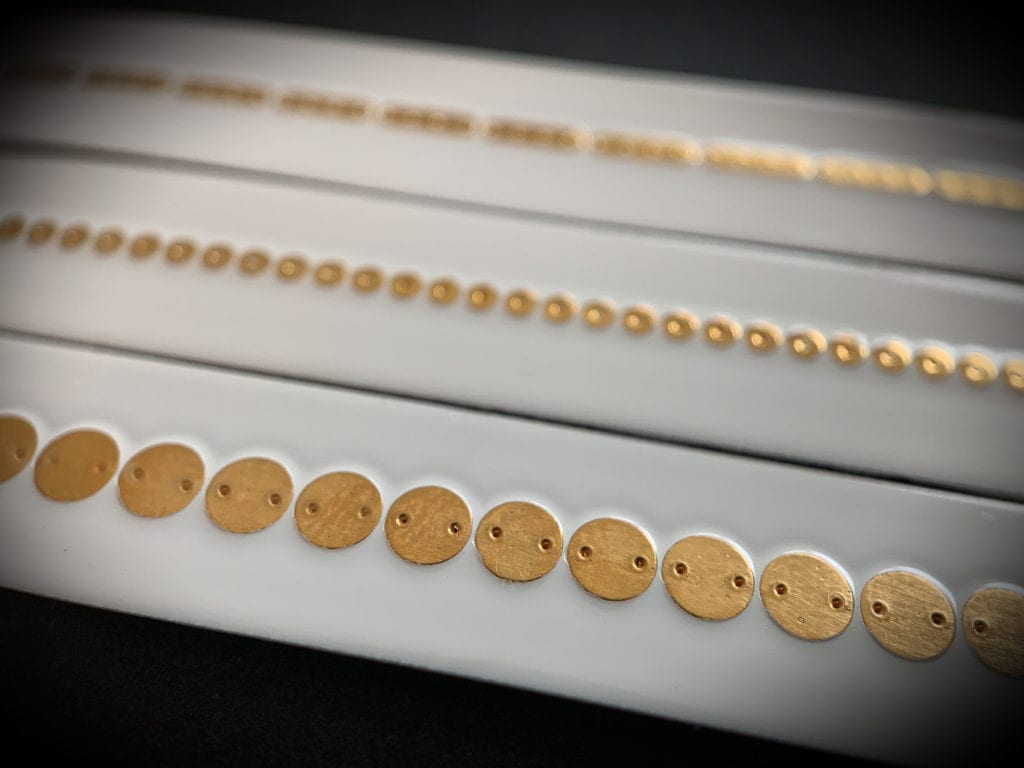

Segmented lightning diverter strips form an ionized channel above the surface they are installed on. This channel directs lightning energy safely toward a grounded metal structure while greatly reducing destructive heat that can damage the surface of a wind turbine blade.

Segmented lightning diverter strips consist of small metal buttons (0.3-mm thick, 10-mm wide) on a flexible, high-tech plastic material. High-quality diverters like StrikeTape can survive many lightning strikes while maintaining their original level of protection.

Wind turbine blades are very susceptible to lightning strikes, even when lightning does not directly attach to the blades. The rapidly changing and extremely strong electric fields in thunderstorms create electrical activity along the blades which can degrade the blade’s dielectric strength. Once the dielectric strength is reduced, the lightning protection system on the blade, typically tip receptors, becomes less effective, making the blade more susceptible to additional damage. Segmented lightning diverters can reduce the electrical stress on the blade and maintain the efficiency of tip receptors. Translation: a longer life for your blades and turbine.

Strike Tape Lightning Diverter Strips are made better, to last longer. High-quality materials and superior design protects your equipment and your investment. Get Strike Tape specs here.

Can Segmented Lightning Diverter Strips Protect Against Near Lightning Strikes on Wind Turbines?

Too many wind turbines have inadequate lightning protection to deliver the longevity wind farm owners demand. Even blades that pass annual inspections are likely to have microscopic damage, primarily due to near lightning strikes. To a lay person, the term “near lightning strike” sounds like a “close call.” But that’s not how lightning works.

When a lightning storm occurs near a wind turbine, even in the absence of direct lightning strikes, a strong electric field is at work on the turbine and blades. As the electric field is amplified near the blade tips, air by the tips can ionize and form energetic, high-voltage streamers and leaders, which are also called near strikes. Quite often, those electrical fields – streamers or near strikes – create permanent fissures in the blades’ structure. Although those fissures – which are actually minute holes in the blade – are too small to easily see with the naked eye, over time, multiple fissures result in an electrically “porous” blade, ruining its dialectic strength. That kind of damage can cause significant downtime for your turbine, not to mention expensive repairs.

A high-performance lightning protection system that includes StrikeTape segmented lightning diverters should be a part of every wind turbine’s blade design.

We wrote about the phenomenon of near strikes in an article for Windpower Engineering & Development, where we discussed the implications of these high-voltage leaders and streamers and how wind farm operators can protect their equipment and investment.

Read all about the effects of near strikes in our article in Windpower Engineering & Development, or if you have any questions about protecting your turbines using high-quality lightning diverter strips, contact us.

FAQ

How do segmented lightning diverters protect wind turbines?

Wind turbines often get struck by lightning multiple times per year, depending on where they’re installed. Segmented lightning diverters protect the composite turbine blades by channeling lightning energy over the blade and into the thick metal down conductor. The segments on diverter strips create an ionized channel above the surface of the blade. This channel greatly reduces destructive heat on the surface of a wind turbine blade.

How much voltage is in a near lightning strike?

Near lightning strikes are much lower in voltage and amperage than a full lightning strike. Full lightning strikes are typically 50,000 amps to 200,000 amps. Near lightning strikes can be from 5,000 amps to 30,000 amps, but most are in the 10,000-20,000 amp range.