Should wind farm operators install winglets on wind turbine blades? Is this a worthwhile retrofit to improve efficiency and power output? In this article, we’ll discuss the aerodynamic properties of wind turbine blades and whether or not winglets make financial sense as an upgrade on wind farms.

First: What Is a Wind Turbine Winglet?

Winglets are curvatures in the tip of a wing or blade. The vast majority of wind turbine blades feature straight blade tips, but as engineers look for more ways to improve efficiency, factories are beginning to produce turbine blades with winglets. Additionally, some wind farm operators who already have a straight-blade turbines are hiring maintenance companies to retrofit winglets onto their existing machines.

What Does a Winglet Do?

Because even a 1% improvement in efficiency can make a meaningful impact on the financial bottom line of a wind farm, it often makes sense to make subtle retrofit improvements on existing turbines. “Power Curve Upgrades,” which include but are not limited to vortex generators, serrated trailing edges and winglets, can be expensive upfront costs, but pay for themselves in just a few years.

How do Wind Turbine Winglets Actually Work?

As a wind turbine blade slices through the air, high pressure on the upstream side side causes a lift force that makes the blade to spin. Low pressure air is found on the downstream side of the blade (or suction side).. Fluids (including air) will always move from high pressure to low pressure, and so at the tips of the wind turbine, the two zones of air pressure meet and mix, causing vortexes. These vortexes cause “induced drag,” which reduces the lift and thus efficiency of the blade.

The winglet, because of it’s curved design, keeps the high pressure and low pressure air apart better than a straight tip, thus improving lift on the upstream side of the blade and reducing drag from the vortexes.

Reduced drag = a more efficient blade = more energy produced = more profit for the wind farm.

What’s The Research Say?

According to this research article, The effect of using winglets to enhance the performance of swept blades of a horizontal axis wind turbine, winglets provide an aerodynamic boost to wind turbine blades by reducing the negative effects of vortex airflow at the tips.

This research paper explains that winglets account for a 0.6-1.4% increase in power production, and that the side of the blade the winglet sweeps to can make a big difference. The authors state that winglets that sweep to the downstream side of the blade could have an even greater effect than upstream side winglets. This follows the pattern of airplanes, which typically have winglets facing toward the sky, on the low pressure top of the wing.

The Aerodynamics and Engineering of Winglets: What We’ve Learned From Aviation

Many aerodynamic principles used on wind turbines were derived and adapted from airplanes. Below you’ll see a winglet on a Southwest Boeing 737.

Aerospace engineers seek optimal lift with minimal drag in wing designs, and tremendous financial resources are expended trying to make planes more efficient. Because every gallon of jet fuel counts, some of the world’s best engineering minds have been working on wing design improvements for decades.

The end result? Most planes now have winglets.

Should Wind Farm Operators Retrofit Winglets onto Their Existing Wind Turbines?

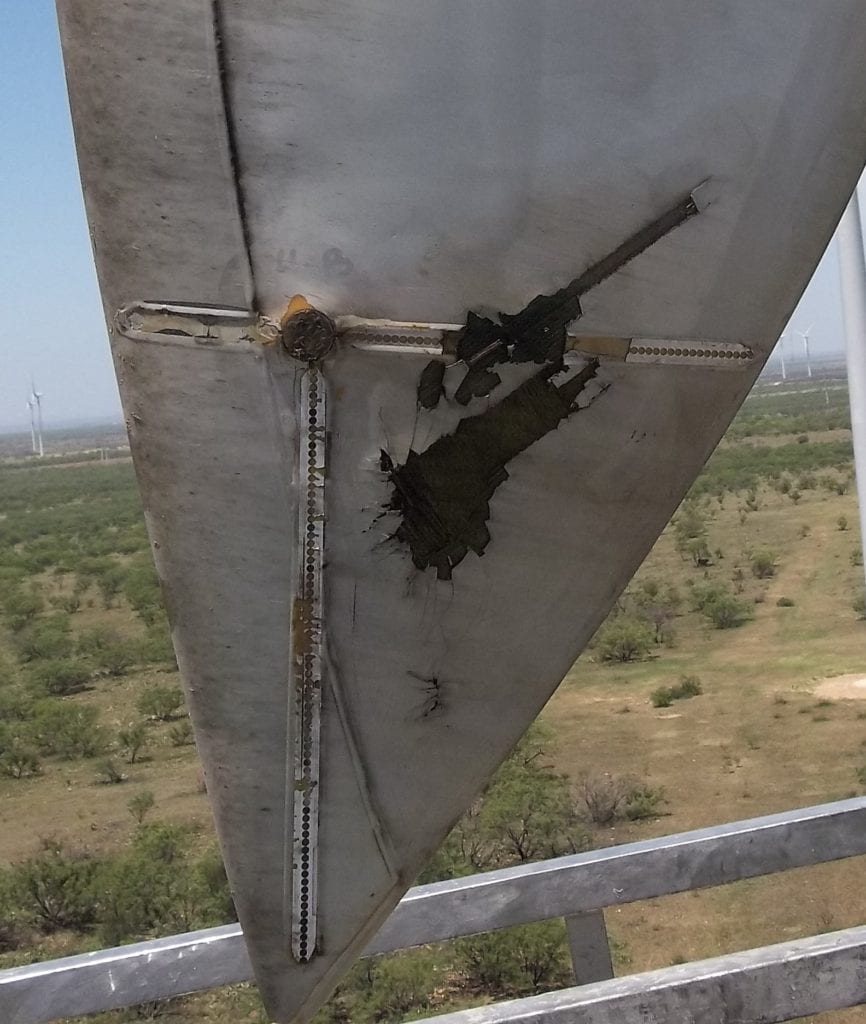

It depends. Though at 1% increase in efficiency can be worth the cost modifying the blade tip and installing winglets, there is one main hazard to consider: the wind turbine LPS, or lightning protection system.

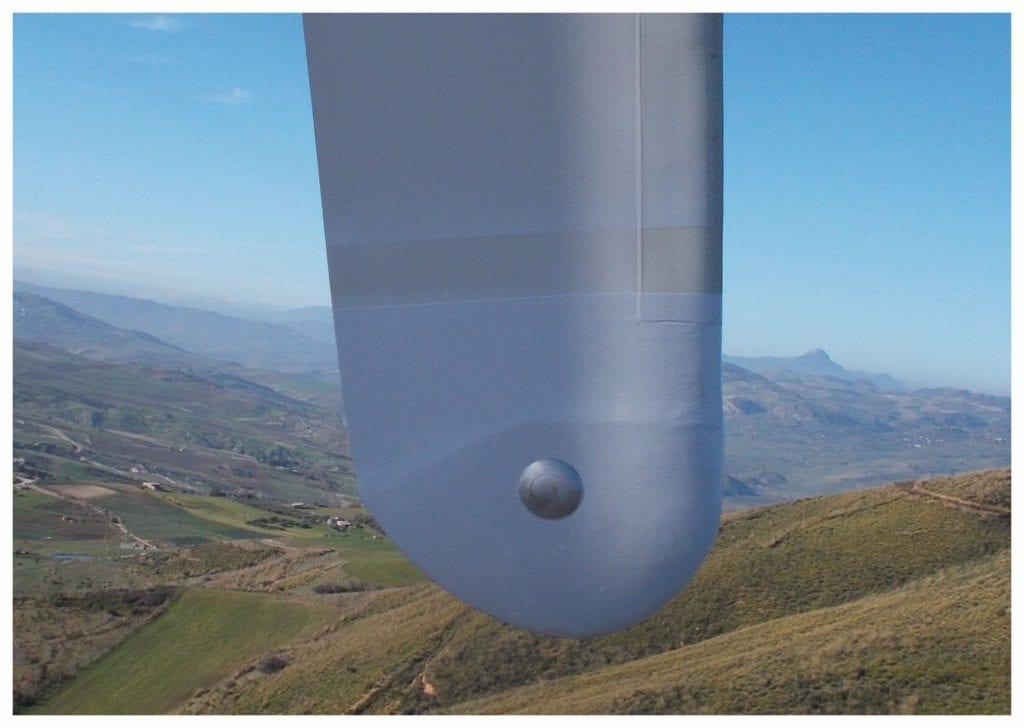

Wind turbine blades leave the factory with a down-conductor and receptor lightning protection system, and it’s imperative that the receptor is as close to the blade tip as possible. Because the winglet extends the blade and sweeps up, the receptor cannot possibly be relocated to maintain its original relative position at the very end.

Wind Turbines with Winglets Will Suffer More Lightning Damage

The result of the winglet retrofit is that the wind turbine LPS now can’t do its job nearly as well, the likelihood of lighting damage increases dramatically for the duration of the wind turbine’s service life. This is a BIG problem.

How To Upgrade a Wind Turbine LPS to Work With Winglets

Installing a wind turbine LPS that works effectively with winglets is a challenge. If you’re a wind farm operator who’s considering installing winglets, your budget should also include upgrading the LPS at the same time.

With a crew of skilled technicians already up on ropes, and the absolute necessity of enhanced lightning protection to account for the reduction in receptor effectiveness, it makes good sense to take care of both at the same time. Save money, save time and avoid headaches.

Every blade is different, so if you need help upgrading your LPS, contact us and we can help custom-design the system that will work best for your turbine. We have complete installation guides and videos to help your technicians install it quickly and easily.

Watch Our Video Clip on Turbine Winglets

On the Uptime Podcast, we discussed winglets and blade extensions: two retrofits that have gained popularity in recent years. Watch the quick clip below for more on winglets.

More Wind Turbine Power Curve Resources

Want to learn about the power curve retrofits that are improving wind farms all over the world? Check out more of our blog, podcast and video content below:

- Leading Edge Erosion: a BIG Problem for Wind Farm Operators

- All About Serrated Trailing Edges

- Wind Turbine Vortex Generators: Do They Work?

- The Uptime Wind Energy Podcast

- Our YouTube Channel with more wind turbine technology talk.

- More Great Articles can be found on our blog

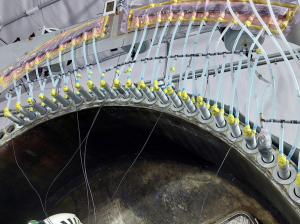

Learn More About Weather Guard’s StrikeTape Wind Turbine LPS

Don’t forget about your lightning protection system. Upgrade your system today – we’ll help make the installation process a breeze.

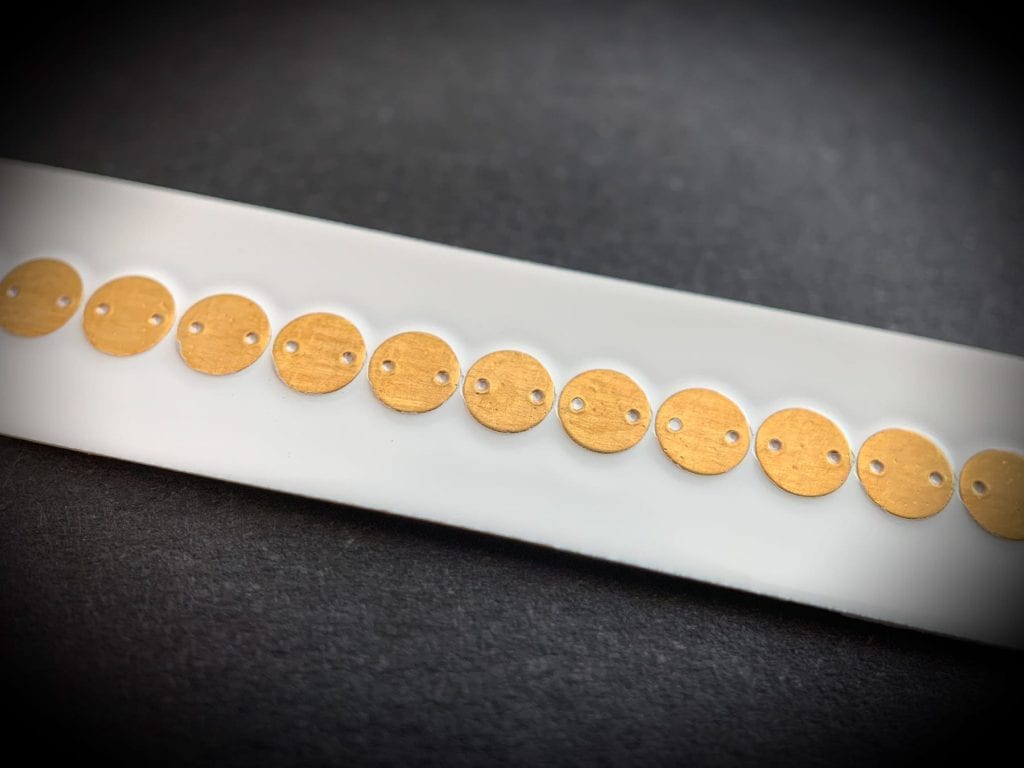

We build and test our StrikeTape diverters to ensure quality, durability and reliability, so trust us to help keep your wind farm running for years to come. Learn more below.