The concept of using wake steering to improve wind turbine energy production isn’t new, but new models and research from MIT have brought the topic back into the news. In the Uptime Podcast EP 129, we discuss the latest MIT study and the viability of wind turbine wake steering to improve energy production. The two-minute recap is below. Tune in to Uptime for the latest wind energy technology news.

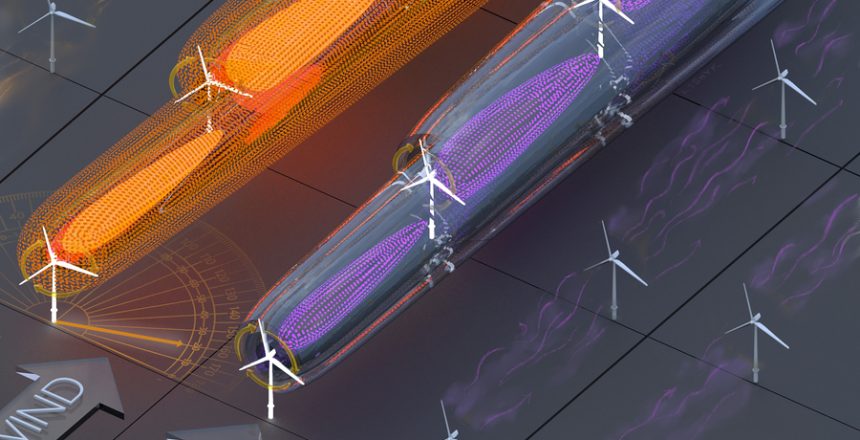

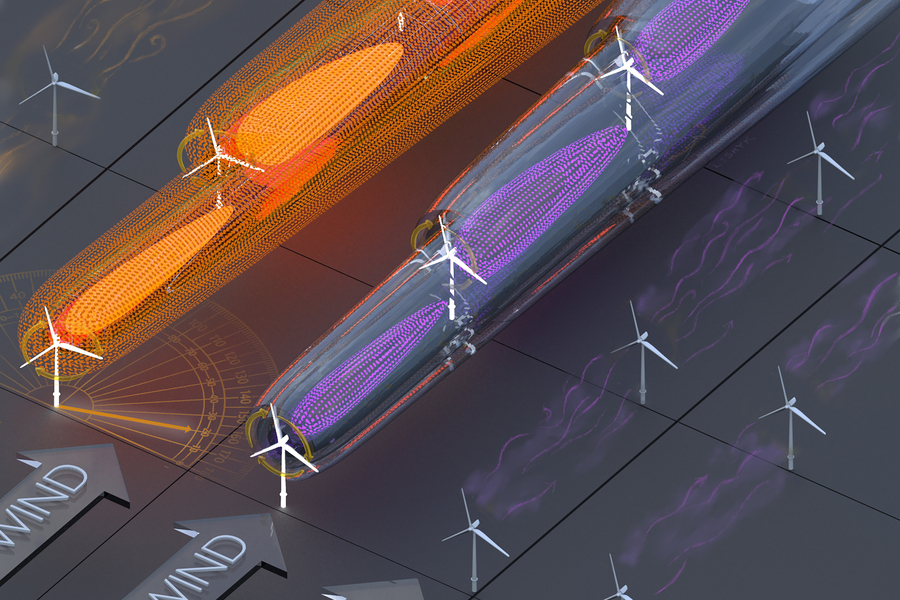

By modeling the conditions of an entire wind farm rather than individual turbines, engineers can squeeze more power out of existing installations.

MIT News, August 11, 2022

Wind turbine wake steering: making a more concerted effort

In highlighting the new study MIT researchers point out that even as wind energy is a burgeoning business and arguably the strongest of renewable energy sources, the majority of all wind turbines are controlled “as if they were individual, free-standing units.” In other words, not very efficiently. MIT’s new (2022) models show how wind farms could see significant productivity increases by controlling the entire fleet to maximize its performance.

The allure for wind turbine owners and operators is that productivity gains could be achieved with existing equipment. The MIT study suggests a 1.2% energy increase can be expected, with up to a 3% increase in “optimal wind conditions.”

Using wind turbine wake steering to increase production

The US-based WindESCo focuses on optimizing individual turbines and fleet-wide performance. Wake steering is a swarm application, the company explained. A precision tuning of all of the turbines can improve the efficiency of the overall wind farming operation. The company says that wind farms lose 5-20% of production to wakes, and tells clients they can expect a 3-5% increase with its swarm technology.

Fine tuning turbine performance is key

Because wind turbines are placed close together to maximize land use, each turbine creates turbulence that affects its neighbors. Somewhat counter-intuitively, the MIT models show real production increases can be achieved by fine tuning turbines, “turning down” production of some turbines to get productivity gains from other turbines to more than make up for the decreased production in others.

Potential problems with wake steering

Wake steering sounds great, you might say, so why isn’t everyone doing it? Good question. “Fine tuning” wind turbine blades almost always involves yaw alignment, which is almost always discouraged by manufacturers. (In other words, it will probably violate the warranty.) Oh, and if you start tinkering with alignment and loads, your insurance company might void your policy. Joel Saxum of Wind Power Lab discusses these issues in more detail in Uptime EP 129.

For more information

The MIT study, Collective wind farm operation based on a predictive model increases utility-scale energy production, was published in the journal Nature Energy. ArcVera’s 2022 white paper, Estimating Long-Range External Wake Losses in Energy Yield and Operational Performance Assessments Using the WRF Wind Farm Parameterization, examined turbulence and wake losses in two onshore wind farms and one offshore wind operation. WindESCo has written about yaw alignment (and misalignment), and we’ve interviewed insurance experts in the wind energy industry.

TLDR?

Tune into the weekly Uptime Wind Energy podcast where we discuss wind energy technology and interview engineers who break down the science.

Wind turbine wake steering is a method used to “fine tune” the performance of numerous wind turbines that are relatively close together, as in a wind energy farm. While the goal of wake steering is to increase production of the entire operation, it usually involves decreasing the production of some turbines to reduce the overall wake loss. Wake steering has been used around the world and typically results in very modest production increases.