Wind energy production in the US has grown tremendously in the past two decades and as annual energy production (AEP) has increased, so has our understanding of the risks associated with lightning strikes on wind turbines.

We’re very excited about the incredible strides being made in understanding (and preventing) wind turbine lightning damage – because the better we understand and manage those risks, the better we’ll be at producing energy and protecting people and property.

We’ve been writing about specific damage to US wind turbines for nearly a decade, and working with wind energy operations, technicians, researchers and wind farm operators to improve lightning protection for even longer. Read on for a brief round-up of what we’ve learned and what we’re working on right now.

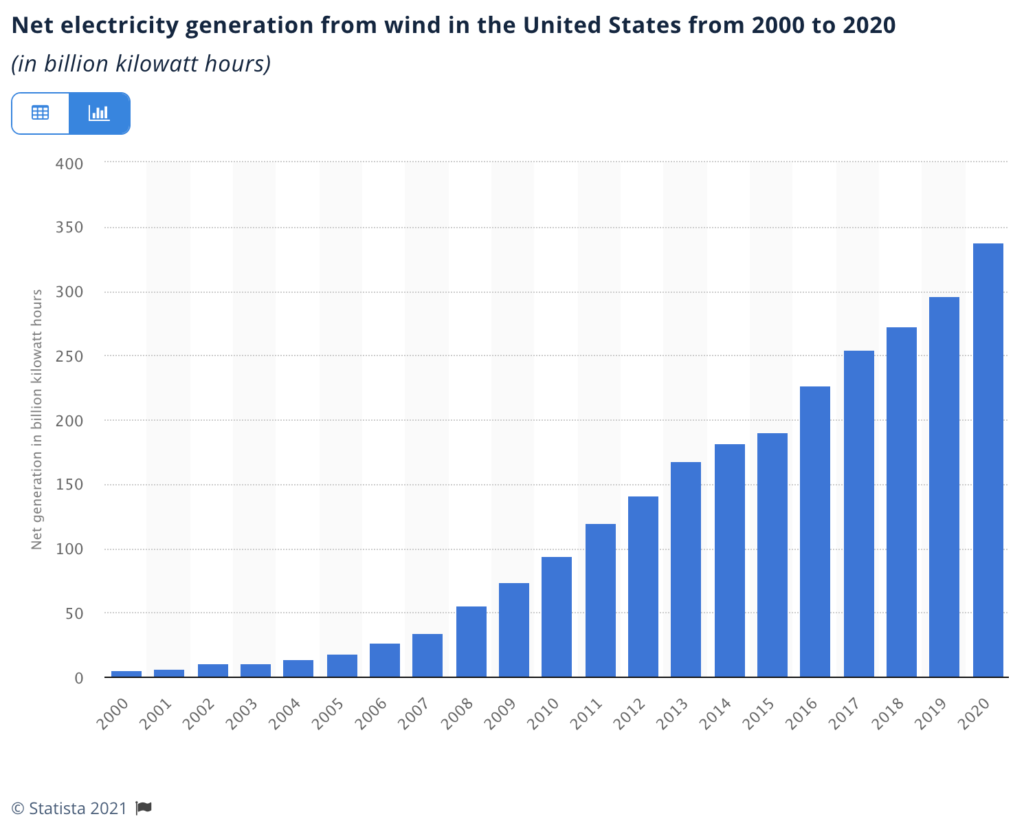

In 2020, around 337.5 billion kilowatt hours of wind electricity were generated in the US. Reaching ever-increasing targets puts more pressure on manufacturers, with owners bearing increasing responsibility and liability.

Source: Statistica

New Research on Wind Turbine Aerodynamics

Without a doubt, any change to the shape of of a wind turbine blade surface can result in aerodynamic performance changes. And unless you’re regularly doing drone (or live) inspections, chances are you won’t see those changes until the changes decrease your production levels, or your blades experience obvious failures.

While wind farm owners consciously make aerodynamic changes to improve production and/or to reduce noise (think power curve or trailing edge add-ons), weather causes leading edge erosion and less obvious, micro-changes to the blade surface every day. Even minute changes affect the turbulent flow, which, we have seen in the lab and in live installations, can alter lightning strike paths.

See the practical turbine maintenance activities that most improve performance and reduce risks

In other words, fresh-from-the-factory lightning protection systems only work for so long. Different factors on every site contribute to lightning risk. Unfortunately, adding lightning protection in the field usually means expensive downtime.

StrikeTape is field-tested and does not affect blade aerodynamics. Download the assessment or schedule a call to get more information.

Blade Design, Materials Change: Lightning Danger Persists

As blade designs evolve with improvements in aerodynamics and materials, lightning continues to be a problem. Blade lengths increase, tower heights grow, and turbines are placed in more lightning prone areas. And yet, the lightning protection systems remain mostly unchanged from turbines manufactured in the 1980’s. The recent lightning problems in the U.S. Midwest are indicative of lightning problems around the world.

Owner/Operators Shoulder Responsibility for Lightning Damage

Regulations and standards tend to lag behind technology and development in any rapidly-growing industry, and that’s certainly true of wind energy. Although IEC 61420024: Lightning Protection of Wind Turbines was approved in 2019, we’re still not seeing wide adoption from manufacturers across the industry.

Unlike in the aerospace and other industries, currently the responsibility is not shouldered by manufacturers. Rather, the responsibility and liability for lightning damage to wind turbine blades (and other property) is borne by turbine owners and operators, DNV GL Engineers Alex Byrne and Matt Malkin explained in an interview last fall:

“Once the turbines are in the ground and they’ve been operating for some time, then we can look at the actual lightning, environment, how much lightning the turbines have experienced over the number of years that they’ve been operating.”

— Alex Byrne, DNV GL, talking about field assessments, Uptime podcast EP 28

Assessing Your Turbine Blades Lightning Risks

Every wind turbine installation has unique factors that affect wind energy production and the turbine blades’ potential for damage. Some factors are easy to assess based on manufacturer, model, and materials; others are very site specific. Soil composition and upwards lightning (prevalent in, but not limited to, Japan and other locations with turbines at high elevations) are just two examples.

Lightning protection systems installed at the factory offer a good start to managing your risks, but most turbine owners find out diverter strips and other aftermarket protection is required to protect their investment.

How dielectric changes affect wind turbine blades.

To find out more about how your blades are protected and for help assessing your lightning risks, contact us.