Blade damage is the greatest risk to lost revenue. Simple maintenance activities can help prevent losses.

In most industries, including wind energy, maintenance is typically viewed as a preventative activity intended to reduce safety risks and the potential for catastrophic failures. There’s no doubt it does both. However, in any wind energy operation, regardless of the age, size, or manufacturer of the turbine tower or blades, maintenance activities also directly affect the productivity and profitability of the entire operation.

Maintenance issues are especially important for mature installations where owners want to maximize productivity for another 10-15 years. After more than a decade of working with wind turbine owners, as well as numerous services providers, we’ve learned a lot about blade maintenance.

Better Blade Maintenance = Better Production

The most obvious (and economical) maintenance activity is to regularly clean and inspect blades. (Aerones, among others, is working hard to revolutionize cleaning.) Blade damage is by far the greatest risk of lost revenue and downtime, amounting to 41% of all structural damage reports.

The reasons clean blades are more efficient and last longer are obvious, but worth noting – I’m always surprised at the operations that don’t include regular cleaning in routine maintenance procedures.

What you need to know and do to maintain optimal blade production:

- Clean blades are lower-risk/higher productivity blades. Any contamination is potentially conductive, and oil, salt and dirt all contribute to material degradation.

- Dirty blades present dangers. Dirt is a lightning magnet, so keeping the blade clean of any buildup reduces the opportunity for dirt to settle onto the blade and attract lightning. What builds up? Oil salt, soil can collect on blades and it also builds up in seams, eventually allowing water to get into the blade or between composite or resin layers.

- Clear drains promote proper drainage. Any reduction in effectiveness of the blade’s drains can allow blades to retain water. Your worst nightmare: lightning travels through the highly conductive water trapped in the blade, splitting the blade in two. (It happens.)

- Clean blades are easier to inspect. As with any piece of machinery, you want to be able to spot minor problems while they’re still minor (and relatively inexpensive to address).

New Blade Designs Mean Increased Costs

Occasionally we hear concerns from operations managers who suggest that it’s hard to justify investing more in required maintenance or repair of “old” blades. Generally, they change their minds when they look at the actual costs. Not only do most “old” blades have a lot of production left in them, there are several simple upgrades, such as vortex generators, available to increase the production of those blades.

Listen below for our conversation with Nicholas Gaudern of Power Curve, who shares his expertise on wind turbine blade aerodynamics and power curve upgrades:

Sadly, the alternative (not investing in your equipment) can be really expensive. New blades are costly and increasingly complex. Any technician you talk to will pretty quickly agree, it’s often difficult – and sometimes, impossible – to replace components in isolation. As a result, any component failure can result in more downtime and more expensive repairs. Or worse, replacing the entire blade when something goes wrong.

The hard and soft costs of replacing just one blade can be prohibitive, and quite often, when one blade needs to be replaced, the others are not working optimally, either. Of course, the structural health of your blades has everything to do with your operation’s productivity.

Did you know?

Even blades that pass annual inspections are likely to have microscopic damage, primarily due to near lightning strikes.

Typical Causes of Damage to Wind Turbine Blades

Wind turbine blade damage can occur in several ways, and almost all of those ways have to do with three things: dirt, cracks, and moisture.

Any of the three main culprits decreases the blades’ aerodynamics and disrupt air flow, forcing the turbine to work harder to produce power. The dirt comes first, which is why cleaning your blades regularly helps prevent things from getting worse.

And over time, wind turbine blade damage only gets worse.

Even small amounts of dust, oil and debris can settle into seams on the blade. Wherever it collects, it can hold water, and eventually, seep into materials. Ice accumulation is also a big problem.

But even before that happens, the blades’ weight increases (due to retained moisture), forcing the turbine to work harder to produce energy.

The Cycle: Moisture, Dirt, and Damage Leads to Reduced AEP

As the cycle progresses – and it doesn’t take long – moisture can permeate the blade’s interior. Even very small amounts of moisture can compromise the resin, or the blade’s core materials. While polyester and vinyl ester resins are more likely to degrade in water than epoxy resin, all of these materials show significant reduction in material strength.

Wind Engineering published an excellent review, Damage mitigation techniques in wind turbine blades, that details specific concerns with the various resin materials and debonding issues that affect wind turbine blades.

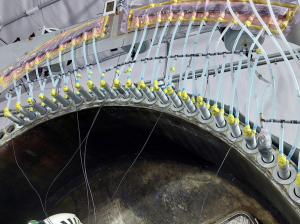

And whenever water is able to enter the blade, there’s a significant increase in lightning risks. Lightning, of course, is one of the major causes of wind turbine blade damage – and almost certainly the most serious in terms of safety, as well as cost. There are many factors that can increase lightning risks, and some of those change over time. Blade dielectric strength degrades over time, affecting lightning protection, for example. (Here’s a short video explainer.)

Having an understanding of the risks associated with your blade’s materials, design, age, and weather conditions is critical – and so is regular cleaning and routine maintenance. If you have questions about turbine blade maintenance, you should contact Aerones. If you have questions about lightning protection systems for new or older wind turbines, we welcome your call.

Allen Hall, founder of Weather Guard Lightning Tech, wrote this blog post.

Allen is an aerospace and electrical engineer with expertise in lightning protection, electromagnetic interference and radio frequency transmission. He has worked on aerospace designs for Boeing, Airbus, Embraer, Gulfstream, Bombardier, and others, and the StrikeTape lightning diverter technology he designed to protect wind turbines is used in wind farm operations worldwide. Subscribe to the Uptime podcast for insights into the wind energy industry and lightning protection technology, or contact Weather Guard Lightning Tech to schedule a consultation with Allen.