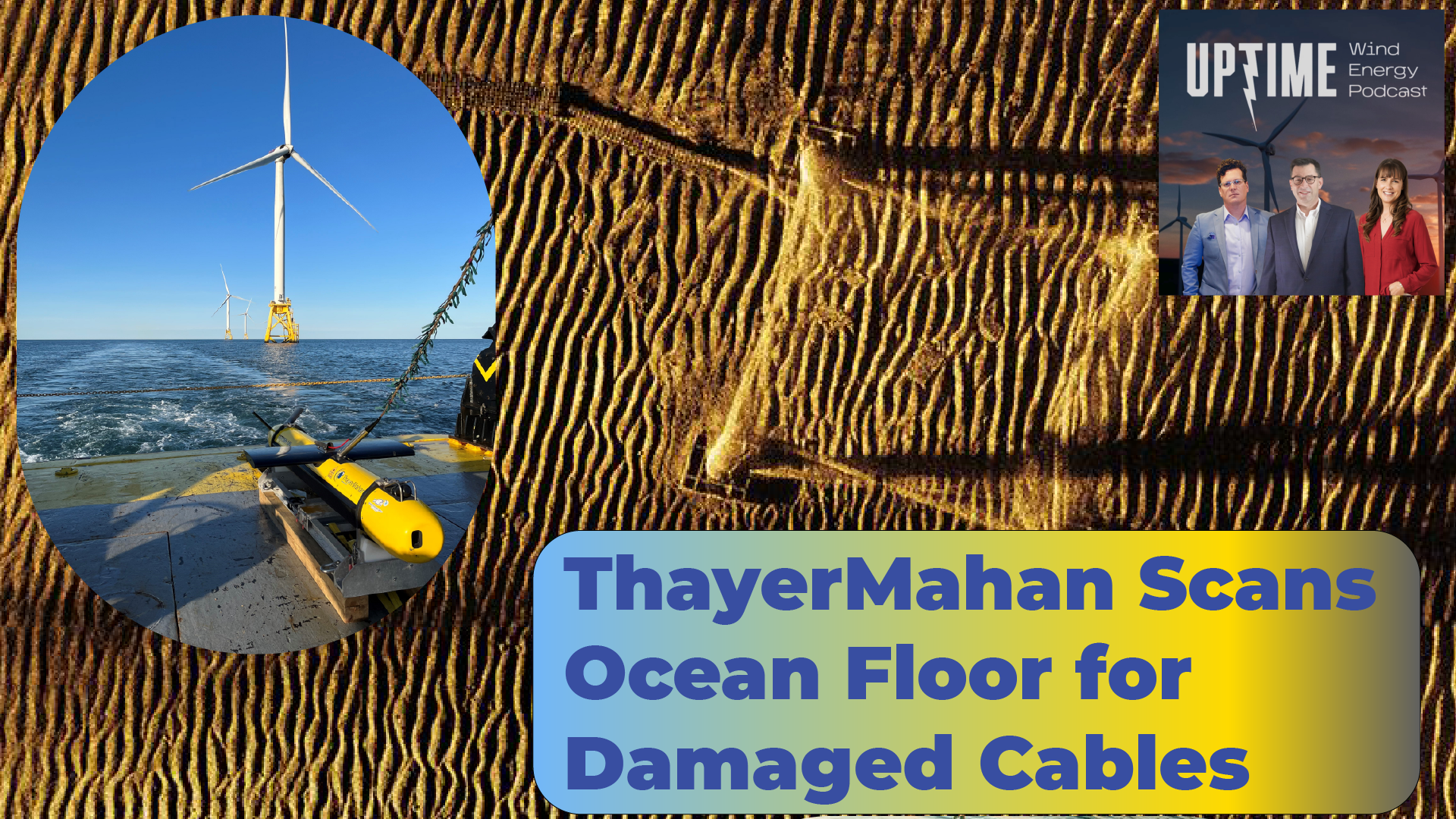

What’s the most profitable way to manage a wind farm? Should you rely on OEM maintenance contracts, Independent Service Providers, or self-perform? Philip Totaro from IntelStor explains the data that show ISPs provide the best returns, and we consider the warranty and insurance implications. Allen, Joel and Rosemary also talk about Perceptual Robotics. The Greek company, flush with new investments, is evolving and heading to the US. Speaking of perceptive, ThayerMahan’s sub-sea system incorporates AI algorithms and synthetic aperture sonar to inspect cables on the ocean floor. Joel says it’s potentially much better than human monitors, but are there drawbacks? Other new technology we examine in this episode: how do new retrofit blade-heating systems from Borealis work?

Longroad’s Milford I & II are our wind farms of the week.The Utah farms are expecting AEP improvements of up to 4%, thanks largely to WindESCo’s Swarm implementation.And as environmental concerns are impacting companies like SouthCoast Wind, an Uptime bonus episode considers new data on whale deaths. What have we learned?

Visit Pardalote Consulting at https://www.pardaloteconsulting.com

Wind Power Lab – https://windpowerlab.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Podcast: Play in new window | Download

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Uptime 153

Allen Hall: Well before we got on the podcast today, I was just looking through the news and noticing that an Irish guy had been attacked by a chicken and killed. So , you think that the only you know animals out there are trying to kill you? A polar bears, especially in the wintertime, but I guess we have to watch out for chickens now.

Allen Hall: Joel, did you see that?

Joel Saxum: I thought you were gonna open up with MidAmerica pausing wind turbines cuz of the Siemens Gamesa blade coming down. But we went to chickens in Ireland. Does it, is it, was it on, was it on a wind farm or something, or, or why is it?

Allen Hall: Well, it, it was near a wind farm, but the thing was that this chicken attacked his legs and like pierced his arteries and he bled out.

Allen Hall: So I’m like, seriously thinking about going to Chick-fil-A at night just for a little bit of payback .

Joel Saxum: And, and making sure that you, making sure that your life insurance policy’s up to date.

Allen Hall: Yeah. Right. I mean, there’s only so many animals you can deal with at one time, but, and I’m not a big fan of chickens.

Allen Hall: As, as our producer will tell you, chickens are not my favorite animal of the animal world. Yeah. So now I’m on red alert today. I don’t know why that, that still sticks in my head. Because there’s a lot of windows this week, and I was going through it the last couple of days. Like, oh, there’s some really good stuff to talk about.

Allen Hall: And then, Irish guy and the chicken pops up. So , we’ll see how, how this podcast turns out cuz we’re gonna have Philip Totaro on and Phil’s here right now. Phil, you wanna describe what you talk about this week?

Philip Totaro: Thanks. Allen, it’s probably not as interesting as chickens, but it’s an opportunity for insurance companies though.

Philip Totaro: So. Hi, I’m Philip Totaro, we’re here to talk about independent service providers. And the cost effectiveness of their maintenance regime on total revenue output for asset owners.

Joel Saxum: Cool. And after we talk with Phil, we’re gonna jump over to the UK to some of our Greek friends, Kostas, Dimitris and Derek Rutherford over at Perceptual Robotics.

Joel Saxum: Talk about what their drone solution is doing and kind of how it looks like to advance in the market. And their big contract, they, they hit with NL. And then we’re gonna go from the sky to the sub-sea. So we’re gonna talk about ThayerMayhan inspecting some sub-sea cables with synthetic aperture, sonar and AI.

Joel Saxum: They’ve done a, a really cool launch and test study off of the East coast in the US and we look to be ready for the wind farms to get installed for inspections.

Rosemary Barnes: And we’re gonna talk about de-icing wind turbine blades, my favorite topic, and about options that there are for retrofitting wind turbines that were installed without de-icing, but turned out to need it.

Rosemary Barnes: And specifically about Canadian company Borealis and how they’re tackling that issue. And I promise that there won’t be any more talk about chickens in the rest of the episode. So if you. If you were just about to skip to the next episode in your queue because you’re not that interested in chickens, there’s no need to worry.

Allen Hall: And our wind farm of the week is Longroads Milford I and II wind farms out in Utah.

Allen Hall: They’ve been working with Windesco and it has some really good results from that system. So they’re our wind farm of the week. I’m Allen Hall, president of Weather Guard Lightning Tech, and I’m here with my good friend from Wind Power Lab, Joel Saxum and Intelstor’s, Phil Totaro and the soon-to-be guest of the Fully Charged Live Event in Australia, Rosemary Barnes, and this is the Uptime Wind Energy Podcast.

Allen Hall: Well have Phil Totaro back from Intelstor and Phil has some really good data on the, in influence of independent service providers on maintenance contracts and how that can affect the bottom line. And Phil, you’ve been looking at this data for a while, and I know your, all your people are back behind the scenes.

Allen Hall: Churn and, and cranking on the data that you have. Can you give us a, just sort of a highlight of what you’re finding in regards to the ISPs?

Philip Totaro: Yeah, thanks Allen so it’s been about six or seven months that we’ve been kind of digging through all this. And, and what we actually are in the process of releasing now in terms of an update is some analysis on asset profit.

Philip Totaro: And digging into the maintenance, the influence of maintenance type. So our asset owners who self-perform actually getting the most out of their assets are asset owners who rely on an OEM doing better or our asset owners that utilize an I S P doing better. With that in mind, we, we kind of dug into the data that the energy Information Administration publishes on plant level production.

Philip Totaro: And we’ve combined that now with analysis from FE’S publication of a lot of the utility power purchase contracts. And what we’re seeing is that for asset owners who. Utilized an independent service provider, the total revenue that they generate per installed megawatt is actually higher. So it’s about the entire market average is about 1.6 million per megawatt in total revenue.

Philip Totaro: Regardless of asset age, et cetera. The, the entire market average is 1.6 million, but for the assets that are I s P maintain, they’re actually seeing the lowest is about 2 million per installed megawatt and goes all the way up to about 2.6 million per installed megawatt in, in total revenue.

Philip Totaro: So the one question that kind of comes out of this is, well, maybe two points. One is the insurance companies. and financiers involved in this industry seem to have this perception, like the OEM is the way to go with a maintenance contract because you’re gonna get the me best bang for your buck. But the data doesn’t necessarily prove that out particularly when you, you kind of standardize and, or normalize, I should say, for.

Philip Totaro: You know, asset age and for what’s, what’s kind of the, been the recent trend in power purchase contract prices, which is to say they’ve, they’ve come down quite a bit. Normally ISPs maintain older assets. OEMs are, are more prevalent on younger assets. But it’s the older assets that are actually outperforming the younger ones at this point, well,

Allen Hall: Does that even happen?

Allen Hall: If you’re assuming you have an OEM and an I S P and they’re doing the same level of maintenance? You’re getting a drastically different result at the end. Is it just because the ISPs are using the better WD 40 and greases in the turbine or, or what? It, it, it’s a basic repair. Right? Unless they’ve got some magic sauce, which they

Philip Totaro: may, you know, it’s, it’s funny when, when ISPs actually have access, so this, this is gonna get into a whole, you know, discussion, I guess, on right to repair and data rights and access to information, et cetera.

Philip Totaro: I think what’s happening is the, the OEMs might not actually be performing the maintenance according to their own specification. They, they are desperately trying to claw back lost margin on their turbine sales and so they, you know, there have been some younger projects that have had a lot of teething issue.

Philip Totaro: You know, you’ve, you’ve also got a lot of these younger projects that have significantly lower PPAs and like I just mentioned, I mean, you, you, you know, we’ve tried to, to normalize our data to take those, you know, cheaper PPAs into account. But at the end of the day, if, if you’ve got a, a cheaper ppa, you, you need to.

Philip Totaro: Maximize the amount of performance that your asset can can achieve. Otherwise, you’re seeing a substantially longer payback period on, on your asset regardless of whether or not it’s generating cash and, and, you know, making money, your, your net positive return on capital is, is, you know, three or four times longer than what it used to be.

Philip Totaro: With, with a, a young asset in a, you know, below $20 a megawatt hour, p. . So there’s still some digging that I think we have to do to really try to understand why. That said, I think the ISPs are the ones that have a vested interest in ensuring that they can get older assets to produce, because with a higher p PPA price the asset owner who potentially doesn’t want to repower their asset until after their PPA expire.

Philip Totaro: Wants to see, you know, a, a maximum amount of revenue and a maximum amount of output. So, you know, the, the routine maintenance that the I S P will, you know, apply is probably benefiting these older assets and maintaining those assets, the in, in their level of perform. versus some of the, the teething issues that have been seen with,

Joel Saxum: with younger projects.

Joel Saxum: This spans a couple of things, but I’m, I’m asking about in your analysis, have you guys taken into consideration the, some of the geography? Because right now we’re just talking about the United States market, right? So, so, so when I say geography in the United States market, I’m thinking, okay, in California, California was really where wind started.

Joel Saxum: In the US I. At a larger scale, right? Like they were the first ones to put in big wind farms. So a lot of those older assets are in California that are con continuously running. Some of them, you know, they’ve been cruising out there for 30 years and that’s fantastic. So they’ve been maintained well and they’re still producing power.

Joel Saxum: But the other side of it is in California also, the labor laws have created much higher. Rates to be on site, whereas you might be able to put someone out on site for 30 bucks an hour. In Iowa, you’re gonna pay that same person 40 bucks an hour in California. So that might, that might shift the, the levels of basically dollars per, per megawatt, depending on what labor market you’re in.

Joel Saxum: But the other side of it too was, you know, when we talk about these older assets still operating, I think some of those are in more favorable. Wind conditions to, to operate better. And I don’t know, maybe I’m not saying that correctly, but I know a lot of the ones in California, I’m just thinking like, you know, there’s like Zone Z50’s and stuff out there that have been churning out power since the nineties.

Joel Saxum: And they don’t require that much maintenance compared to some of these newer turbines. They don’t have as much o and m costs, right. You’re not, you don’t have the tip speeds, you don’t have all kinds of l e p issues. So, so maybe that’s some of that factors into your calculations as well. Yeah,

Philip Totaro: it’s, it’s a great point.

Philip Totaro: We, we haven’t dug into, some of those, those issues yet, but that’s, that bears more investigation.

Joel Saxum: Yeah. And maybe it’s too granular, right? For, I mean, you guys are doing so much analysis every wind down to the wind turbine level across the entire United States. When you start talking about individual labor laws in different counties and states, that might be just a little bit much.

Joel Saxum: You might have to grow your team a little bit more before we get into that, but just a, just a thought. So

Rosemary Barnes: the work that I do in my consulting business is nearly exclusively with OEMs with service agreements which is really different to when I used to work in Europe and North America, where I think it’s not as prevalent.

Rosemary Barnes: And what I am anecdotally seeing is a lack of motivation. That’s in my, you know, my gut feeling is that that’s the, the reason for a lot of the, the problems is that there is no incentive for the manufacturers to really be proactive with things. You know, they get things finished, they do their repairs to the sufficient standard.

Rosemary Barnes: Eventually after, you know, a lot of , a lot of arm twisting, and, you know, by the time I get involved it’s because the process hasn’t, hasn’t gone smoothly. And I know that there’s a lot of different levels of OEM service agreement, right? Like some of them are just really basic. If it’s you know, we’ll do the scheduled maintenance then, you know, a little bit more, they might you know, be a a bit more proactive about when they do that maintenance.

Rosemary Barnes: And then right up at the top level, you see some sort of upside sharing so that there is an incentive to you know, do more than the bare minimum to make sure that you’re doing maintenance in low wind speed periods or, you know, when. Cheap. And probably, you know, some incentive to do predictive maintenance or something like that.

Rosemary Barnes: And I was wondering if you’ve separated out those different service agreements or if there’s anything in the data that would confirm my gut feeling about why this is happening. Cuz yeah, like I contrast it with the the owner operators or ISPs that I worked with in in, in a lot in Quebec.

Rosemary Barnes: Actually. There’s some good ones in Quebec. And in other, other parts. of the world, and they’re like really going after it, you know? They, they want to try something different to maybe get an extra half a percent a e p. They’re not just like, ugh, we’ve gotta, we’ve gotta locate a new blade somewhere in the world.

Rosemary Barnes: We’ll get back to you in two years when when we’ve found it, you know, it’s totally different. Level of, yeah. Proactivity, we’ll call. Does the data confirm that or am I just, you know, , is that just my biased impression from my small number of sample points? No, it’s,

Philip Totaro: it’s a great point, Rosemary. So I, I, what we can probably say at this point, we, we haven’t picked apart like every single type of service contract.

Philip Totaro: All we are, we sometimes have visibility to is whether it’s like you know, an OEM contract versus asset owners self-performing, their mainten. . But for the ones where we do have that, keep in mind, like even Vestus, when they do like an AOM 4,000 or AOM 5,000 service agreement, you’re still getting like basically standard maintenance, but you’re also getting the warranty and, and you know, like, so your, your standard maintenance contract might cost you for instance, like, you know, 30,000 US per turbine per.

Philip Totaro: But your AOM 5,000 might cost you like 45,000 or close to 50,000 per turbine per year because they’re including the warranty cost in, you know, on top of a standard maintenance contract. So it’s funny because, you know, it’s, it’s not like if you sign one of these maintenance, OEM maintenance contracts with an extended warranty on certain components, you’re not getting any better.

Philip Totaro: Standard maintenance, like you’re not getting like some higher quality magic, you know, lubricant that goes into the gearbox that does special things that they wouldn’t otherwise do. So it, it’s, you know, it’s just a question of are they actually doing the routine maintenance in accordance with the.

Philip Totaro: Manufacturer spec or are they trying to cut down on cost, like you said, and, and maybe holding back on performing some of the even the standard maintenance, particularly if the data that the OEM might have would indicate that, you know what, maybe that specification we wrote that said you have to, you know, update the lubricant on the yaw bearing every year.

Philip Totaro: Or maybe it’s, doesn’t have to be every year, you know, or every six months. You know, maybe you do it. Year, every 18 months or, or something like

Joel Saxum: that. So, to, to add to that, Philip, what we were talking about, and, and I don’t wanna, I’m not trying to paint anybody in a bad light. This could be an I s P, this could be anybody.

Joel Saxum: But say you have a warranty, and this is just a a, a particular example I’m thinking about, right? Say you have, if you’re on the hook for the warranty, right? You’re, you’re at a whatever level of service agreement. , you are now on the hook for the warranty and in the neighboring wind farm, you’re not, and if you look at two of the same turbines and one of ’em, or they both have the same kind of like say something like there’s a pitch bearing that’s kind of going bad on one of ’em, that you’re on the hook for the warranty, I would say before it actually fails.

Joel Saxum: You have more of an incentive as that that that contract holder and say like, Hey guys, we know this one’s probably gonna be bad. Let’s get one on. We’re gonna, we’re gonna replace it when we have a low wind day or whatever that part may be, because we know it’s kind of going bad. Whereas on the other one, you’re gonna be like, soon as it goes down, they gotta pay us.

Joel Saxum: So maybe we’ll just wait. Does that make sense? That might

Philip Totaro: be part of the answer, Jill, that that does make sense and I, I don’t have, there’s not enough publicly available data to be able to confirm it. , I think based on what we all know about how the market works, I think that is, that is

Joel Saxum: a logical assumption.

Joel Saxum: Nobody’s putting that on the internet. . What I think

Philip Totaro: this does is it brings up the question, like Rosemary mentioned, do we need to continue doing contracts, service contracts, you know, per turbine per year with, you know, annual escalators and availability guarantees and all that? Or does Thisitit. The need for the industry to shift more towards, you know, a a maintenance contract per megawatt hour that they’re producing and, and performance bonuses may be, you know, and like a revenue share may be included.

Philip Totaro: I think that’s something that I think needs to be talked about a bit more potentially in relation to this very interesting outcome. Well,

Allen Hall: if you’re an independent service provider, And you’ve just listened to this discussion, you need to get a hold of the Intel store data because that data is extremely valuable to you as you’re approaching operators this season.

Allen Hall: And the way to do that is to go to intel store.com or connect with Phil Totaro on LinkedIn. Phil. Hey, thanks a bunch for being back on again. This is really great.

Joel Saxum: Get the latest on wind industry, news, business, and technology sent straight to you every week. Sign up for the Uptime Tech newsletter@weatherguardwind.com slash news.

Allen Hall: Perceptual Robotics, which is a Greek drone company, is ready to enter the US market and they have some backing by Brook Street Equity Partners in London. They’re looking to push, make a big push into the US in the first quarter of this year. So Perceptual robotics actually is, comes out of Bristol uk and they’re, they’re pushing their autonomous drones and advanced robotics.

Allen Hall: They have a lot of backing. They have previous investments from international investors, TSP Ventures, future Fund, humble Holdings, and Meta Valin v. So it’s a relatively new company too. It was really started in roughly 2019 and they’re off to the races. So Joel, I know we have talked about this off air.

Allen Hall: There’s a number of drone companies in, in the marketplace right now, particularly in the United States and having perceptual robotics join that list. It sounds like a pretty. Heavy load to take on the US is a difficult market.

Joel Saxum: Yeah, I think that they did something smart. So I’ve talked with the team over there Demetrius and Costas at the beginning.

Joel Saxum: And then Derek Rutherford does a lot of their BD and stuff for ’em. Great group of guys. Very intelligent. They’ve got a good product on there. What I’ve seen from their AI actually is it’s very good. Which I don’t say a lot of, a whole lot of blade inspection ais. But what they did, I, I was talking to them last fall and I thought it was very smart and I, cuz I, we were talking with Wind Power Lab and those guys about doing some, some tests and some things.

Joel Saxum: We looked at some of their data and what they said, you know, right now we just wanna hold up. We’re gonna, we plan on doing about a, you know, 500 to a thousand inspections in. and we don’t want to go anywhere else besides there for this year. And I thought to myself like, oh, why wouldn’t you take the opportunity to come over to the States?

Joel Saxum: And I was like, you know what though? That’s pretty smart. You know, just kind of fine tune your craft before you decide to take it, you know, into eight time zones away and, and send people out into the field. So I know they have signed a big, a big deal with nl. . So if they’ve got nl on the books, that may be their vehicle to come to the states.

Joel Saxum: NL of course developing a lot in the, in the states and quite a few assets over here. So I would say that would be a smart move on their part. But again, like you said, there’s a lot of players over here and a lot of people are shifting to that inspect on your own. Kind of you know, operational idea and I think that’s smart.

Joel Saxum: I know Narth Lab is doing that. I know Thread is doing that. I knows Schmidt is, has a OP option for doing that. So I think some, most of these platforms that have like the super big, you know, likes Schmidt, the other side of theirs is like, you can go and do a kind of a base inspection and go check a look at it by yourself with this drone, which is like a Mavic B j I like little tiny thing with a 4K camera on it.

Joel Saxum: Or you can call us and we’ll do it with a phase one or something like that. Right. What’s a 45 megapixel camera? So, different tiers, different levels, but I think if companies are being smart right now, they’re trying to get into the drone game. It’s so flooded. The Skys specs is out there. You got the drone base, well, Zeit View now out there kicking butt as well.

Joel Saxum: You know, between the two of them, just drone bass and, and Skys specs, I think they. 50, 60, 70,000 inspections a year, which is just crazy. So you have a lot of little kind of, there’s like little boutiquey ones and startups and you know, like Thread I think actually came out of the University of North Dakota.

Joel Saxum: Correct me if I’m wrong, if everybody knows any data on that one. But they were, there was, they were a company, I think at one point in time, and I might be mixing two of them, but there was another one called Blade. and I think that actually might be what Thread was, and then they turned into thread.

Joel Saxum: So you have, there’s a couple little tiny ones kind of floating around in the US and then you have the big dogs. But yeah, a tough market to break into. I think if I was putting energy into developing robotics right now, it would be in a different, a different real. , to be

Allen Hall: honest. Well, are they even drone companies today?

Allen Hall: Are they just software

Joel Saxum: companies? Yeah, that’s, that’s a good point, Alan, because I think the perceptual robotics uses the D G I M 300 as their platform. So they have a little hardware package, or not a little maybe, but a hardware package that goes on it that has the camera on probably lidar and some other things that most all of ’em other have.

Joel Saxum: Localize themselves and maintain distance, but then it’s software, right? I know one of the companies I talked to a year, a year or so ago in their autonomous navigation software, there was over 150,000 lines of code. So , you’ve gotta be, you’ve gotta be a pretty developed software company to be able to maintain something like that in an autonomous flight situation, right?

Allen Hall: And North Labs is doing something similar. So I, if it is moving to a software, Eventually they’re just gonna have to get out of the hardware business. The hardware business is going in a completely different way, and it’s expensive business to be in. Does that then drive the marketplace in terms of the drone companies are now software companies and instead of offering a technician and a drone and a to pilot the drone, is it just then you’re gonna rent the drone from a Skys specs or a, a drone?

Allen Hall: Type company and it’ll do its thing and you don’t even, you’re not involved with it. You know what

Joel Saxum: I mean? If I’m the asset owner or the o and m contract holder, that’s what I would want because I would wanna be inspecting me like, you know, there’s a downwind day like, Hey guys, go grab the drone and do some inspections.

Joel Saxum: Instead of having to have a guy on site, he’s gonna be here for these two weeks. We’ve gotta cater to that contractor the whole time. Make sure he’s, you know, make sure we’ve got the turbine shut down and this one’s shutting down as this one’s moving. And, and if we have to pay for, you know, if the weather moves in, all of a sudden we’re paying 90 bucks an hour or whatever weather time for this guy.

Joel Saxum: If I could avoid that, I would. And then, then it, then it comes down. the data. Right. So does it though. Well, when you introduce these little tiny drones, they don’t get as good a data with the camera. Right. So, and I know, okay, so from the Wind Power Lab side of things, we vet people very hard on their image data quality.

Joel Saxum: Because if you don’t have good image data quality, your, your AI just won’t work. Or if you have a blade engineer or some other engineer looking at the inspections, it’s hard to tell, right? Like it’s why people have got away from the, the robotic. Camera on the ground because you can only get like two millimeter per pixel resolution out of it.

Joel Saxum: That’s no good when you’re looking for

Allen Hall: hairline cracks. Well, it’s just a matter of time though, right? Give it another year and the the camera, they’re just gonna get better and better and the drones are gonna get smaller and smaller or more accurate. Be able to fly

Joel Saxum: closer. Yeah. That’s the tough thing right now, right?

Joel Saxum: Because you could just get closer. Right? That’s, that’s the solution. But a wind gust comes along and. , not a lot of these drones can correct themselves that quickly.

Allen Hall: So it is a very, very, I think, a very difficult marketplace at the moment to be in the United States, there’s so many big players who have like a, a skys specs, who has a tremendous amount of funding to fight off new entries into the marketplace, which is what will happen.

Allen Hall: For sure. So perceptual robotics will have a very interesting spring and summer of the United States. We’ll just have to keep an eye on it because marketplace is, is changing rapidly there. Joel, on the East coast, there’s been a number of projects wrapped around subsidy cables, and what are you gonna do with these subsea cables?

Allen Hall: Once they’re laying on the sea floor, you’re gonna need to inspect them, particularly if you have an idea that something is wrong. How are you? Find out where the damage is. Those cables were miles and miles and miles long. So the Connecticut base there man has been working with their underwater scanner called C Scout, and they did a little bit of an experiment back at the end of 2021 with a grant from the New York State Energy Research and Development a.

Allen Hall: And the National Offshore Wind Research and Development Consortium where they took their CS Scout drone behind a ship and they, they put some damage cables on the sea floor and used that CS Scout system to determine if they could see or image the damage. Accurately. So it’s a, a real world experiment, not something done in the lab, not something theoretical.

Allen Hall: They actually went out and did it. And the images that I’ve seen and there was just they had a, a presentation at Northeastern University a couple of months ago. The images were amazing that CS gout system system can see the, can image the sea floor extremely well. So they’re thinking that this may be a way.

Allen Hall: Really detect cable damage as the cables are being laid. And if there’s something were to happen later on in service, they could relatively quickly identify it and get it fixed. And Joel, you know a lot about this underwater scanning technology. You wanna describe what the CS Scout is and what the main is up to?

Allen Hall: Yeah, so

Joel Saxum: the, at the basics of it, you gotta understand that while the, the general population doesn’t see this, there. Thousands of miles of pipelines and thousands of miles of, of data cables and power cables and all these kind of dust stuff. On the subsea, right, on the subs, on the, on the sea floor. So if you go into the Gulf of Mexico and you start, if you start googling some stuff about like we’re, where’s oil infrastructure in the Gulf of Mexico just right off of our coast in the US that you probably have never seen before.

Joel Saxum: There is miles of. Everywhere. I mean, it’s like, it’s like someone through spaghetti noodles out there that are that are a hundred miles long. So the in pipelines and export cables power cables, data cables have been out on the sea floor for. , you know, since the 1940s or 1930s. They’ve been there for a long time, and there’s a lot of ’em.

Joel Saxum: So they’ve been inspected in a multitude of different ways forever now. A lot of that used to be, and there’s still, there’s still contracts that go on like this where literally there’s one guy flying an ROV and ROVs a remotely operated vehicle. It’s basically like a, some of them are about the size of, I don’t know a small car like a Mini Cooper.

Joel Saxum: A lot of ’em are about that. And they have a guy orga sitting there driving a thing, and then another person sitting with like five screens in front of him, staring at those screens for 10 and 12 hours straight. Just like this. If you can see me on YouTube, And that, and that’s all they do, right? So they’re just looking at it going like, and it’s a visual inspection of this pipeline.

Joel Saxum: So they’re looking for certain things like anode depletion, right? So you have to have anodes on the pipelines so they don’t interact with the sea water and, and cause corrosion. So they’re looking for anode depletion. They’re looking for if they had a rock dump on the pipeline to keep it in place when they built it.

Joel Saxum: Is the rock dump still stable, right? Or has there been scour under the pipeline or under the pipe? Or under the pipeline or power line so that there’s a gap there now, and now that pipeline is sagging or power line is sagging. If you do that, you start to stretch the cable, right? So they’re, they’re looking for these things on basically live video feeds, and it takes forever.

Joel Saxum: It’s super inefficient. And you have teams of people out there reviewing video for hours and hours and hours on it. The other side of that is it’s a human eye. They’re going to miss. , it happens all the time, right? There’s no way that they’re gonna get, you’re gonna expect someone to sit out there for a four week shift and stare at screens and, and catch every little issue that they find.

Joel Saxum: So AI has come along in the last few years. Almost every operator of ROVs digital video recording systems, anything that works offshore or subsea has some kind of AI either on their platform or in the works in the background that they’re utilizing to help alleviate the, the stress on the human and the human air.

Joel Saxum: Cruise along that pipeline and, and all of a sudden AI is picking up anodes and it’s picking up free span and it’s picking up dent. If it sees any kind of al in the pipeline that’s off, like it got squished, it will pick that up. So that’s great. But you’re still looking at video. Now. The, some of the newest solutions are, well, we can also take that AI and feed it back into the control systems of the ROV and have it fly itself.

Joel Saxum: So now they’re taking. Vehicles and just throwing ’em in the water, getting ’em to the pipeline and saying like, all right, we’ll pick you up in a thousand miles when you l reach shore, and that vehicle will just cruise along that pipeline the whole time, localizing itself by basically slam slam navigation autonomously, and then pop up and say, here’s all your data problem there.

Joel Saxum: Okay, now you’re running across, say you’re in the Red Sea and you run across a shipping lane and there’s been a ship that went by and now the ship has stirred up the. You can’t see anything visually. You’re, you’re, you’re, you’re up a creek. You can’t, you, you got no more navigation. What happens then is that little autonomous vehicle will pop up to the surface and then try to ping itself or let you know, Hey, back in control center, like we got a problem here, blah, blah, blah.

Joel Saxum: That’s where you have sonar come in. So sonar operates in, you can get high resolution sonar as well. They’re, you know, it’s not like you’re fishing boat sonar. These things are $250,000 a piece. . And so you can get a couple fishing boats for that, at least inland fishing boats. But so, so now you have that resolution, but that resolution from those is good.

Joel Saxum: It’s good enough to see, you know, infrastructure on the bottom. It’s good enough to know there’s a pipeline there and to maybe see some free span. If you get real close to it down in 10 meters or so, you can see some detail, but you’re still looking at a ground sa. If you’re flying 10 meters above it or five meters above it, you’re still looking at a ground sampling distance.

Joel Saxum: a centimeter, two centimeters sometimes, depending on what kind of data you want to have. So the next step in all of this is synthetic aperture sonar, which is what Thayer Mayhan is using in this project. So synthetic Aperture Sonar is a, it’s not a new technology. It’s been used by the military for a long time.

Joel Saxum: They use synthetic aperture sonar to see through clouds and stuff for military operations in the sky. You can also, there’s some really cool research to actually. Sub surface assets on land with it, like to look for pipelines by flying a drone over the top of ’em. But that’s, that’s not what we’re talking about here,

Joel Saxum: And so what they’re doing with a synthetic, a synthetic ATRA persona here is the, it turns basically like what would be a four 80, a four 80 p picture. And I’m just trying to, to, to kind of. Make it seem a little bit easier, a four 80 p picture into what would be like an eight k. Right. That’s the kind of difference right now we’re talking imagery.

Joel Saxum: This is point data, right? It’s, it’s, it’s bounce back point data. It’s backscatter, so it’s still sonar beams pushing bouncing out and giving you data back. But now that you’ve got such high resolution, you can start to apply AI algorithms to that vector data that, that point data as well. So they’re really like, they’re getting, they’ve gone.

Joel Saxum: looking at it visually, to looking at it with ai, to navigating along in it with ai, to switching to sonar and now switching to, you know, synthetic aperture sonar and now using AI with synthetic, synthetic aperture, sonar. And it, it’s, it’s, it’s the next, next level, right? This is it’s super cool to see them doing this because if you followed anything offshore wind, you know that there’s a billion dollar loss in the North Sea, right.

Joel Saxum: with, with export cables, right? And if they were able to efficiently and accurately inspect those things regularly, the North Sea has one to three knot currents on the sea floor 24 7. So that creates scour, that creates movement, that creates a dynamic environment where you just think, oh, it’s the sea floor.

Joel Saxum: Like it’s in the water in the bottom of my glass. No, that water’s always moving. So when the water’s always moving, it A lot of, you know, the, the silt and the sand moves and the pipe, the, the export cables can be moving around, and if the rock dumps missed them on their initial dump, then that export cable can just kind of like move along the, the subsurface.

Joel Saxum: So if they can do it more efficiently, more accurately, and with ai, where they’re cutting some of the human error out, it’s a, it’s a, a win all around for the offshore wind in the US

Allen Hall: and globally, I assume it can detect things like, Gas line breaks, like in like Nord Stream, those kind of things, right? I mean that, that’s the technology you could use it for is does that mean that they would have to be continually out in the water?

Allen Hall: Monitoring for the movement of cables, particularly in places that they haven’t been before.

Joel Saxum: Well, with the new technology, with ai and slam navigation, you can launch this. You can launch a an A U V key side, you know, at the port, and then send it out, and then it can surface when it gets out to the wind farm.

Joel Saxum: After it’s inspected, that whole length of cables, download the data back to shore and you can give it a new mission. Okay, go down again. And I want you to follow these cables out to the. Interconnects within the farm. Follow, inspect all of those. You could have a resident robot out there running, you know, there’s, there’s a company in Canada right now that’s making a robot that the fuel, the fuel cell is hydrogen and they’re going 4,000 kilometers on one, basically one charge.

Allen Hall: Well, Rosemary loves hydrogen, so there you go. Two solved .

Joel Saxum: Yeah. Yeah. If you, I mean, if you can do 4,000 kilometers of you can inspect man. All the wind farms in the New York. Bite in one go with that.

Allen Hall: Is that the next move for Skys specs is to move into the underwater drone

Joel Saxum: market? I don’t know they, unless they hire some new people, it’s, there’s a lot of people in that space that’s a very niche industry with a lot of knowledge and it’d be tough to just move into it.

Allen Hall: Yeah. Well, it does seem like a difficult problem to solve and it, it’s, One of the few research things that I’ve seen that has direct application to offshore wind in the United States. They can use that tomorrow. Even with Block Island, it has some images of the Block Island Wind Farm, which were really interesting to see on the website.

Allen Hall: So check out their main on website. You can see some of these images. They’re really impressive, Joel, and thanks for that update because the technology is beyond me at this point. But that was a really good summary.

Joel Saxum: Lightning is an act of God, but lightning damage is not actually is very predictable and very preventable. Strike tape is a lightning protection system upgrade for wind turbines made by weather guard. It dramatically improves the effectiveness of the factory LPs so you can stop worrying about lightning damage.

Joel Saxum: Visit weather guard wind.com to learn more. Read a case study and schedule a call.

Allen Hall: Or Wind, which is a company based in Waterloo, Ontario, Canada has a blade de-icing system. And of course, cuz Canada’s so dang cold and they need blade de-icing systems up there. And it has for me you little bit of a unique twist. It, it has a heater and a blower in. Space of each blade, which I guess makes sense, right?

Allen Hall: But then they have like an inflatable tube that runs along the leading edge of the blade in a, in like a piccolo tube situation, which is something we would use on aircraft to heat the leading edges of a wing to get the, the pressure and the heat distributed more evenly. That’s what it’ll look like to me on the videos I’ve seen.

Allen Hall: And I, I want to talk to Rosemary about it because she’s our resident blade deicing, anti icing expert. Rosemary, have you seen this system up close or maybe from afar and, and what are your general thoughts on something basically anti IC. Upgrade or mod. So

Rosemary Barnes: you said a piccolo tube. Does that mean like the instrument of piccolo is a tube with holes in it?

Rosemary Barnes: Yes.

Allen Hall: It’s it a reference to the instrument?

Rosemary Barnes: I’m not sure if it does have holes. Oh, really? Is it just jumping heat out? I, I mean, they don’t have heaps and heaps of. Information on their website, but I feel like it’s just a duct that they roll out. It must taper otherwise. You’d have to have either a very small tube the whole way through, which would have a lot of pressure loss or it wouldn’t be able to go very far.

Rosemary Barnes: Yeah, so I mean, to answer your question, yes, I, I’ve seen this, I, I, I’m pretty sure I was aware of it when it, that was started in about 20 16, 20 17 or something. So that’s when I was, you know, heavily, heavily, day to day, focused on, on deicing all day long. . So this company, it’s one of only a couple of methods that you can use to retrofit an existing wind turbine with a de-icing system.

Rosemary Barnes: And that’s especially important in, in Canada. They were some of the first to put wind turbines in icing areas, and some of those early wind farms did not realize how much of a problem that icing was going to be. So you see some wind farm owners that. Suddenly faced with 10, 15, even 20% or more a e p loss from icing.

Rosemary Barnes: And you, you know, obviously that’s like absolutely devastating. You don’t normally deal in tens of a percent of, of losses in the wind industry. So they’re scrambling to find just absolutely anything that they can to. Yeah. To, to claw back some of that. So the Boreal system, it’s a hot air based system.

Rosemary Barnes: They put a giant hair dryer effectively and the root of the blade, and then they roller ducted out through the leading edge. They blow hot air through. Through the leading edge of the blade, and then it probably just comes back through the, the blade wherever it can, the air comes back. So it’s not, not super controlled.

Rosemary Barnes: There are some manufacturers who make a a deicing system for their blades that also use hot air. LM or j a ha have one or had one. I’m actually not sure if they’re still using it, cuz they’ve got another one as well now. And then Bestus also. Had one kind of tried to change, maybe changed back or moved to a hybrid system.

Rosemary Barnes: Again, I’m not not a hundred percent sure where they’ve ended up. Encon as well. That’s another company that used hot air. And then the other alternative is a resistive heater. So usually that’s done by, you lay carbon fiber over the leading edge and then you apply a current to the carbon fiber.

Rosemary Barnes: Cause it’s got some, it conducts, but with some resistance. And so it heats up just, you know, like any kind of electric heating element. And that’s much more, more targeted cuz you can imagine if you put the heating element right on the blade surface where the ice is, then it’s very you know, relatively easier to melt the ice off compared to the hot air systems, which require you to heat up a lot of the blade that doesn’t have ice on it.

Rosemary Barnes: So you need heaps and heaps and heaps of power to for a hot air system that its first drawback. and then, and, and I mean, we’re talking as much power. If you wanted to keep the whole blade ice free, you’d need as much power as the whole wind turbine was producing. So yeah, it’s not, it’s not feasible to you know, take ice off the, the whole blade.

Rosemary Barnes: In all conditions. A hot air system or any system is only gonna work in a certain subset of conditions. And for hot air, it’s gonna be at relatively mild temperatures and over a relatively small area of the blade. Yeah. And then there’s some other disadvantages with the hot air systems in terms of all the components that you’ve got and they’ve got heaps of moving stuff.

Rosemary Barnes: So, first of all, you’ve got the fan that you’ve gotta put near the root. There you can buy a fan off the shelf that has been tested, you know, for, you know, hundreds of thousands of, of operational hours, but, The fans were not developed to go up in a wind turbine, which is, you know, got a lot of vibrations.

Rosemary Barnes: It’s also rotating, the fans also rotating, so you’ve gotta be careful about how you align axes. Otherwise you can end up with the whole thing shaking itself apart quite quickly from gyroscopic effects. Yeah, and there was one, one of the early, the one of the manufacturers who. One of the earliest de-icing systems did shake apart , a whole fleet of of fans in their de-icing system when they, when they put them up.

Rosemary Barnes: But it happened very quickly. So they, you know, they soon, soon realized their mistake and and got back to fixing it. And hopefully it wasn’t, you know, a huge amount because it was you know, first trial. So I assume they wouldn’t have gone too big. But yeah, that can happen. Yeah. Other disadvantages?

Rosemary Barnes: The other big disadvantages, the duct, the flexible duct wind turbine blade is a really high strain operating environment. You know, they just, they bend a lot. So you’ve got all these bends constantly happening. You put a flexible duct inside of blade and you, you can imagine every time the blade flexes, then this duct is gonna rub a bit on the, on the side and you know it’s gonna happen.

Rosemary Barnes: Thousands, hundreds of thousands, millions of times eventually. And my personal experience was that These surprise you how quickly they can wear out. I remember one test that I did in the lab showed, okay, this will last the full lifetime of the wind turbine blade safety factor of like 10 or 50 times.

Rosemary Barnes: It was huge. It was like, yep, this is fine. This will never replace. I went up there, climbed up there three months after they were installed and it looked like Wolverines had been let loose in there. Everything was just shredded. It was, it was incredible. How. Little, my lab test had to do with the reality of what these blades looked like.

Rosemary Barnes: So we had to change that, that design. Quick smartt obviously, cuz you can’t be going up there every couple of months to replace ducts. I don’t know what materials that they’re using, but flexible stuff in wind turbine blades sucks. I mean you can kind of probably get some sort of intuitive understanding by thinking of things that, that Flexible things that move a lot.

Rosemary Barnes: So if you think about like a sail on a boat or a flag, you know, those things get, get tatty, right? Especially a flag. They, they get tatty quite quickly. That’s the kinds of you know, operating environment that you’ve created for this flexible duct. So I think in general it’s a good principle for anything you’re putting in a wind turbine blade to not, not have anything flexible.

Rosemary Barnes: It’s, it’s challenging. All of my biggest component headaches that weren’t related to lightning were related to flexible components. Yeah. Of one, one kind or another. So yeah, that’s two problems that the Boreal system’s going to have. I haven’t seen a lot of information about how they’re actually going in the field.

Rosemary Barnes: They do have systems out in the field. They have referenced journal paper on their website that kind of makes it sound like it’s sort of validated their performance. But it hasn’t actually, if you read it, it’s, it’s saying that that’s not what this is trying to do. Where, you know, we’re looking at trying to figure out what’s the right method that we would use if we were going to validate.

Rosemary Barnes: So that’s a bit different. So my. Yeah, so I guess I should say I have, I have no real experience with the, the design and the materials that they’re using. So I, I couldn’t comment, but. based on my experience with making very similar systems work I’d be really surprised if this was an effective or durable solution.

Rosemary Barnes: I, I bet that you have to replace those ducts annually would be my expectation. or bring them in at the end of the season. I don’t know. It’s probably got a pretty narrow band of operating temperatures. You know, I’d be surprised if you could use it much below, say, minus five degrees or something like that.

Rosemary Barnes: But then again, that does capture like a really large amount of icing icing events usually get worse, icing around zero than you do at colder temperatures. . But the fact of the matter is that if you have installed a wind farm and you have icing that you weren’t expecting, you don’t have the option of saying, okay, well I’ll go back in my time machine and say I would like the , the icing package on my, on my wind turbine, please.

Rosemary Barnes: Y y you’ve got few options. You’ve got this one from Borealis. And then you’ve got Weiss Tech is the other company I think has been on the, the show before, before my time. They’re, they’re the. Company. I, I, it’s only those two as far as I know, that are offering retrofittable deicing solutions. And, and they have one of those conductive systems like I was mentioning.

Rosemary Barnes: And it’s a huge, huge process. You have to take all the blades down, build a portable factory where you can do, you know, like precision carbon fiber lamination, cuz you can’t, you can’t get wrinkles and stuff in these elements or you’re gonna create hotspots and the stakes are higher with a, you know, with a carbon fiber.

Rosemary Barnes: Them electric system because you, you can set blades on fire that way. Yeah, so. The WiseTech system, I think you’re more likely to end up with something that’s really effectively gonna remove ice in at least moderate to challenging conditions. But gee, it must cost so much to do that. And of course if you’re looking at a 20% AEP loss every year, then you’ve got a lot of , a lot of money that you’re probably happy to spend to.

Rosemary Barnes: reduce that. So I can see why Yeah, the Borealis system, whilst it might not be, it, it’s certainly not gonna work as well as something you would buy from the manufacturer right from the start. But I can see why it would be appealing to, you know, if you don’t have that bad severe conditions.

Rosemary Barnes: I can see why you would try it. I bet it. n not that much. One question though that I do have is how, cuz you know, in the blades that I’ve worked in of, I mean of several manufacturers, the leading edge cavity where they’re putting these ducks, it’s not just an empty space. There’s usually bulkheads in there you know, block blocking it off every, I don’t know, 10, 10 meters or so.

Rosemary Barnes: And I wanna know if they just, do they get in? , get a big Dremel, grind them out. You, they do perform some sort of a structural function. It’s not primarily structural. It’s mostly to help in, you know, manufacturing and stuff. But yeah, it, I, I always wondered, wondered how they actually managed to fit these things in there.

Allen Hall: Well, I, it probably depends on the specific blade type that I think the blades I’ve seen are mostly open on the leading. Take it closer to the tip and then fully all the way down though. Good bit of it.

Philip Totaro: Sure. The OEMs that offer this is like an OEM installed option for a new turbine, will lay a conduit in the leading edge.

Philip Totaro: You know, having precision carved out a piece of the rib, you know, each one of the ribs. If there are, if there. , those kind of vertical

Rosemary Barnes: stays. Yeah. But sure they’ve, they’ve redesigned their blades so that it can fit. , whereas this company’s gonna be dealing with blades that were never intended to have this system.

Rosemary Barnes: I mean, that’s their, their problem. And the tip is exactly where you need, need the air to flow. So yeah, I’m just it would be interesting to, to take a look at a blade that, you know, that’s had this put in and see, see how that works. Well,

Allen Hall: I guess this speaks to how difficult it is to get into the wind turbine market.

Allen Hall: That was my comment. Joel about this maybe to everybody on Slack the other day was they’ve been working on this project for about six years, maybe seven. At this point, it is really hard to get a product onto a wind turbine. It is immensely difficult just because of all the variables that Rosemary you just mentioned.

Allen Hall: There’s a lot of things you don’t know until you get into service. And even if you’re working for the oem, you, you don’t have all the data in front of you. If some part of it is just real world experience, you’re not gonna know until you do it. And then once it, it always goes sideways. Has to, that’s the way engineering is, you know, and it’s, it’s how fast you can recover and it’s.

Allen Hall: Is, is it, is the idea still good enough to pursue?

Rosemary Barnes: You need a wind farm operator who is absolutely desperate because they’re losing so much money and there are plenty of those in in Quebec, , plenty of operators that are pretty, pretty desperate because it’s not only, you know, the very first ones that happened before they realize icing was a thing.

Rosemary Barnes: There’s another problem where you know, people get icing assessments done and. They need the icing assessment to say that there’s not gonna be a problem with icing because that massively affects the financials of the project and that you know, gonna be much less likely to be able to get it financed.

Rosemary Barnes: So the people that do the icing assessments are. In my experience anecdotally they’re routinely underestimating the icing. And so, you know, back when I was working on this, I would say to people below 5% annual icing annual energy production loss from icing. I would not bother with a a system. It’d be better off just turning it off.

Rosemary Barnes: Turning it, it off. Well, you can operate through a fair bit of icing and then turning it off for bad icing. And. You know, above 5%, then yeah, you really want to have a proper system. So, you know, if you get a report back that’s like 4%, but it turned out actually it was 10% losses. Y you know, like, it’s, like I said, it’s too late.

Rosemary Barnes: You can’t go back in time and, and change your mind. And the retrofit options are just not, not good.

Allen Hall: That’s why you need someone like Joel to step in because he’s from Wisconsin. Nine months out of the year, there’s ice . You need someone who’s, who lives up north to tell you it’s

icy

Joel Saxum: up here. I’m, I’m looking on their website right now, the, the Borealis guys and you know, hats off to ’em for, for keeping at it for so long.

Joel Saxum: Like they, they’ve, you know, they believe in their solution. So I’m looking at their map and it says Ontario and a couple of spots in Quebec. Icing there for sure. Rosemary, you know, you’ve spent some time up there as well, but there’s a lot of places in the north on, just on the North American. Continent where there is icing problems, just like this.

Joel Saxum: You can go, you can stay in Canada if you want. You can go all the way across Alberta, Saskatchewan, over to Calgary into bc. There’s wind, wind farms out there that ice all the time. But my, my advice or thoughts would be go to winter, wind in Sweden would be the first one. Talk to all, talk to all the asset owners over there.

Joel Saxum: The, the other stuff would be, look into. Hey, you see, you see an icing event come across. The news call all those wind farms that could have possibly been affected by that because someone that is immediately feeling the pain is more apt to pick up the phone to fix their problem. So like this, right?

Joel Saxum: Right. Now, today I talked to one of my colleagues who’s in. . Whereas at Brookings, South Dakota, he just drove from Minneapolis in a snowstorm in a ice storm all the way out there for four hours. I would call anybody in that corridor I could and get on the phone and just be like, Hey, I know you guys are experiencing icing right now.

Joel Saxum: do you want this to not happen to you? Let’s have a conversation because then, then you can get into the technical details, right? Like Rosemary is saying, if the design of the blade itself stops you like, like if it’s a carbon spa blade, what are you gonna do? Right? Like the carbon spa, there’s no, there’s no opportunity for return air, so it’s only gonna work on certain s.

Joel Saxum: Blade designs, but at the more and more you get into the market, the more you understand exactly what those ones are. Chase those people that have the good blade designs that it works

Allen Hall: on. And Wind Power Lab’s gonna be at winter Wind, right? Joel and Weather Guard, lightning Tech’s gonna be there also up in Sweden.

Allen Hall: So if Borealis shows up, we’ll be there. We can meet up in Sweden. Yeah, absolutely.

Joel Saxum: We’re at o and m down in, I think you guys are going to o and m, aren’t you?

Allen Hall: Yeah, we’re going to a c p O and M in a couple of weeks. In Orlando, it’s not really an icy place. , unlike Winter wind, , our wind farmer of the week is long roads, Milford one and two Farms in.

Allen Hall: There’s, so the two farms were built in like 2009, 2011. There’s 165 turbines, so it’s 306 megawatts total with a mix of Clipper 2.5 megawatt machines, and GE 1.5 megawatt machines. Long Road is based in Boston and they’ve been working with another Boston area company, WinCo. And when Esco installed their swarm system on the Milford site they first began by inter instrumenting 10 different turbines.

Allen Hall: And, you know, the swarm system adjusts the, the yaw of the. Wind turbines, so to avoid wake losses. So it’s a pretty smart system again, with 10 turbines instrumented. And then at the end of 2022, they actually instrumented the whole farm. 165 turbines now have swarm, and they’re gonna be commissioning that in early 2023.

Allen Hall: So, Good news from Windesco. Good news for Longroad at the Milford Wind Farms. Cause they can, they’re predicting a e p improvements of somewhere between one and almost 4%. So that’s a lot of power production over time. So congratulations to the Milford one and two Wind Farm and Long Road as being our wind farm of the.

Allen Hall: That’s gonna do it for this week’s Uptime Wind Energy podcast. Thanks for listening. Please give us a five star rating on your podcast platform and subscribe in the show notes below to Uptime Tech News, our weekly newsletter. And check out Rosemary’s YouTube channel Engineering with Rosie. And we’ll see you here next week on the Uptime Wind Energy Podcast.