Podcast: Play in new window | Download

Allen Hall and co-host Joel Saxum discuss Pearce Renewables’ new state-of-the-art training facility in Dallas, Texas with John Hornbeck and Travis Dees. Pearce is addressing the growing demand for skilled wind turbine technicians through innovative hands-on training methods, including the use of real equipment and cross-training opportunities across renewable energy sectors. Learn more at https://www.pearce-renewables.com/training/.

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Pardalote Consulting – https://www.pardaloteconsulting.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Allen Hall: Welcome to the Uptime Wind Energy Podcast. I’m your host, Allen Hall, along with my co host, Joel Saxum. The wind energy sector is booming, and the Bureau of Labor Statistics predicts wind turbine service technicians will be the fastest growing job this decade. But with great growth comes a need for skilled workers, and training enough qualified technicians is vital to keep wind farm projects up and running.

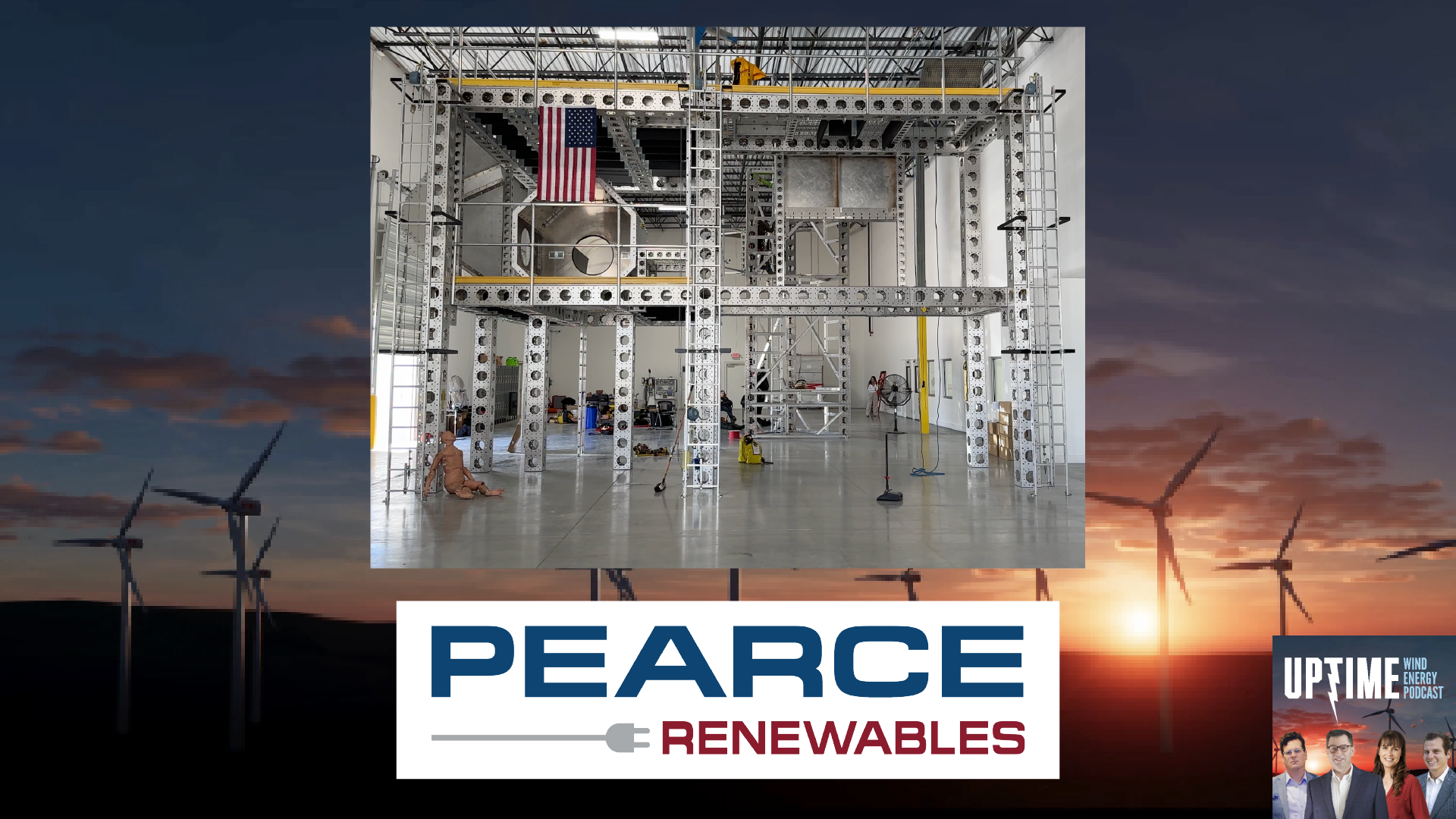

Pearce Renewables has been a leader in technician training, and they recently opened a new training facility in Dallas, Texas. And if you’re not familiar with Pearce Renewables, and boy, you’re missing out. They are the largest ISP in the U. S., and they have a great need for well trained technicians. Our guests are John Hornbeck, Manager of Learning Organizational Development, and Travis Dees, Senior Vice President of Operational Support.

John and Travis, welcome to the show.

Travis Dees: Thank you, Al. Happy to be here.

Allen Hall: Joel and I visited your brand new, fancy training facility in Dallas, Texas. Man, is that thing impressive.

Joel Saxum: Yeah, we were there while you guys were still building things, right? You had people climbing around, you were installing TVs and stuff.

And at that time it was impressive. We walked in, we’re like, wow, look at this place. Look at the size of it. The, I think that to be honest with you, the layout of the training rooms and everything. There’s a lot of things going on there. You’ve got capabilities to run people through a lot of different training mechanisms as well.

Travis Dees: Yeah, when we started the design in the facility, it was trying to build for the future, not for what our needs were today, right? As you said before, we’re growing very quickly and the need for technicians is definitely upon all of us, but us specifically. Making sure they’re trained and equipped properly before they go out in the field is our goal.

We’re trying to build a facility, not just in Texas, but other places as well. Starting in Texas and growing our California facility where the technicians actually want to come. They come there to get their training, but we want them to want to come back. I want them to go to the field, get some hours under their belt, and be like, hey, when do I get to go back to Dallas and hang out at that place?

That place was cool, the trainers are great, they’re really informative. We’re trying to set out, for an awesome vibe. We want it to be. something that our people are proud of. Therefore they take that with them in the field and they, it rubs off on our other technicians and it’s building our culture.

You know what I mean? Like it’s the, we have one opportunity to shine for our employees and this was our opportunity. So we took it and working with, incense and other companies to get all of the equipment inside of the facility was amazing. They designed an awesome jungle gym when I call it, man, that thing is awesome.

And John and the work that he did getting our wind turbine and everything put together and the time frame and the layout works, the flow is really cool. I think it really helps the technicians, keep and retain all the information that we’re feeding them versus them losing it, and what you guys didn’t see is We have a section in there now where all the technicians that come through can autograph a wall which has been fun because some people like to draw some pictures and box letter their names And there’s some really cool signatures and at the same time We wanted our trainers to have a place.

They wanted a training, you know Don’t get me wrong. It’s dallas. It’s hot. Like it was hot there yesterday and those guys were all over that tower. But And we put some big fans in there. It’ll cool it down. And, I keep saying, Hey, it can’t be air conditioned because then they’re going to get they won’t be working in their elements.

The wind turbines, they’re out in all of the elements. So when it’s cold, it should be a little chilly and when it’s hot, it should be warm. So you don’t want to spoil them. No, absolutely not. They, I think they’re already spoiled as it is, but but no, I think the team and John specifically and his team have done a great job with making sure that we had the right equipment, to give our technicians and, even some of our clients they’re people, the best training we could possibly offer up and we’ll continue to grow and improve.

I think there’s always opportunity for improvement, but we’re really excited about the Dallas facility. Everyone that comes in there, we bring a bunch of clients in and yeah. Wow. That jungle gym is, it is a wow factor.

Joel Saxum: So Allen and I came to the facility back in April and you and John welcomed us in and John was giving us a tour of basically the, you have a bunch of classrooms.

Of course, there’s some, of course you have a, then it’s a little bit of a Pearce facility, right? So you’re going to have some meetings or something. You’ve got really nice conference rooms and stuff in there, but training rooms that were air conditioned and nice for certain things. But then when we walked out into the The big facility, right?

The big warehouse type facility. The first thing I saw on the corner was a legitimate nacelle. Sitting there ready to and John was like, we’ll get to that in a little bit. We’ll take a peek at that thing. Let me show you some other stuff. And also, there’s a freaking nacelle in here. That’s amazing, right?

We’ve been to a lot of places. Training facilities and such. And you don’t see that very often for one, right? They’re tough to get ahold of. Nobody wants to that’s expensive. It’s a piece of kit, right? That could be used in something else. So people don’t really want to get it, get you get rid of it.

But the guys are really going to have the capabilities of doing some hands on training. John, you want to walk us through some of the other things that are out in that warehouse?

John Hornbeck: We’re training our employees to be the best they can so that our ISP can keep growing. But the way when we first landed the building, even when it came to the jungle gym, we contracted, worked with ENSA to sell some materials.

But they were open as a company and they said, Hey here’s what some other designs look like. I visited a couple of facilities. I looked at some of other training centers designs. So the team and the trainers and I, we sat down and we drew up, Hey what makes ours different? And we came up with a big U shape.

And that was a little bit too big for what we needed at the time, which was fine, so we cut it down, but just the way that we put thought into it of, hey, here’s all the ladders going up underneath. The deck that, that simulate coming up into a wind turbine main shaft and how we shaped the advanced rescue training section and put things on the second level made it different than everybody else’s and it made it cooler and it looks amazing, and then with you pointing out the wind turbine, that was the other thing, not everybody has a fully, can be powered up or in the middle of powering it up right now, getting it wired to, to put power to it.

at a low voltage so that we can do training and and teach everybody how to work on it without actual high voltage in front of the cabinets. But there’s only a couple of facilities out there that will have that ability to train on a live wind turbine inside their shop. Not just the wind turbine that’s in there that sets us apart as we’re gonna be able to do live power loop training on that.

So we have the same thing. For the solar and the battery storage in the divisions we have partnered with some folks and given us battery storage cabinets and inverters that and helping us power those up so that we can do live training. Not only for customers, but to highlight that to potential clients and things that other partners that we work with.

Allen Hall: So at Pearce Renewables, when you train somebody up, they’re training on real live active equipment. It’s not a simulation. It’s just not a box on a bench. You’re actually using real equipment, especially like battery storage, which is really interesting too because there’s not a lot of training facilities doing that at the moment.

That is a unique piece, I think, because the worst time for a technician is those first week or two or six months where they’re, everything is just new. You’re trying to, to de-risk that in a sense, by giving them access to real working equipment.

John Hornbeck: E Exactly. And that’s what I said that earlier, we wanted to.

Do the things that set us apart from just your, I’ll call it the cookie cutter trainings. There’s plenty of great training facilities out there and there’s, they all do a great job, but there’s a cookie cutter method there. You come in, do the standard training and go out to the field. We wanted to change that.

And add that additional, real live training for our technicians so that, they leave not only knowing how to work safer, but they’re actually getting out there and working smarter right out the gate. So then our customers benefit from that because we’re delivering employees that have been trained on most of the things that they would end up doing in the field for their first few weeks.

Now, there still is field training and very specific. Equipment training that, that not anybody can offer because you might need 15 or 20 different kinds of, cabinets in your shop to train on. But when we offer up that live aspect of training, it’s just that, that one more step, towards getting your cut your technicians out there and just having them hit the ground and work safe and do a great job.

Joel Saxum: Yeah, and you mentioned the components, but you also touched on like a grease nipple. Another thing you showed us, John, was the slew of tools from all kinds of different manufacturers. You guys have there, right? So it’s, they’re not going to be, it’s not gonna be the first time they pick up, a torque tool or something like that.

They’ve handled it. They know the ins and outs of it. They probably already used it, let alone handle it. But they’ve used it on those test facilities that you have. And I know that you were saying, Hey, I’ve got this, we’ve got this set up. But I’ve got these tools coming in and these tools coming in and those tools coming in.

So you, I know you had a lot on the plate there as well.

John Hornbeck: We talked a lot about electrical, but yeah, one of the other things that set this apart too, is you saw all those bolting stands. We built those out of bearings and flanges that are completely simulated to, putting up towers and bolting on hub bearings and putting blades together.

But not only that, it’s exactly the same as getting that live training. We can go into the turbine and we do this. We’re working on the G. W. O. bolting standard, which is pretty new to the industry going across all the training centers. We can, we go into the wind turbine, put the hydraulic or electric, large powered torque tools on the actual main shaft in the pillow block and pedestal blocks.

And so those are common things that the technicians are going to have to check in the field. So they literally are going to walk in there, go into the turbine. Put the tools on these actual bolts and, get a feel for, Hey, I got to watch where I’m stepping, and I’ve got to carry this tool and, get things in place and not leave my cords out where I’m going to trip.

So we’re really proud of the, the bolting and torque class that we’re able to teach there.

Allen Hall: I think one of the issues for new people to enter into the industry, become wind turbine technicians. Is I think there’s a thought, at least I’ve talked to people who have done this, they thought that they needed to have a lot of mechanical experience before they apply it.

Like they needed to be a NASCAR mechanic or they needed to be working for a utility before they decided to apply. Like they thought they had to bring all this expertise to the job. That’s really not true because of all the work companies like Pearce is doing right now, right? You guys are training up people that have general basic.

Mechanical skills to then go off and serviced wind turbines. And I think they miss that point. This is a little bit different than showing up at an auto mechanics place. You’re going to get trained up in wind. You’re going to get trained up in solar. You’re going to get trained up in, in battery storage before you go out to the field.

And that just, I think if a lot of new people to the industry knew that. They’d be much more likely to apply because we’re like, we need like roughly a hundred thousand more technicians over the next couple of years. That’s a crazy number.

Travis Dees: Now, anybody that has a mechanical, electrical or just the want to have a career, call us up, man, call us, we’ll help you get there.

We will get you the training you need. To be safe out in the field and you’re really going to gain the knowledge with time in the field Working with individuals that have that experience, but we’ll make sure before you get out there On your first day, you’re not going to just run away. You’re going to be safe You’re going to know what you’re looking at.

You’re not going to be afraid to get dirty you’re going to have that knowledge with you. So that’s really our goal

John Hornbeck: I would say to say you can go people right out of high school They might have only worked on their bikes when they were young You But we’re going to provide what they need to go work in the field.

So they don’t necessarily need to have any, background. You can be, fresh and looking to go into a different industry because you were an IT person. They’re pretty valuable nowadays, but. It doesn’t matter. We give the training that people need to join our industry.

Joel Saxum: So you have this fantastic training facility that can do solar, battery storage, wind, all the above. We know that there’s some of these industries, like wind, that have this shoulder season, right? Where you’re busy spring, summer, early fall, and then winter comes and you’re, you might not have that much to do.

So if you have the capability of, Training your in house technicians to be able to take on extra tasks in their downtime. That’s a wicked strategic advantage as an ISP.

Travis Dees: Yeah. So that’s one of the things that we focused on and we’re talking about now is how do we’ve done it in the past and we are a smaller company, is you could take a wind technician and go put him in the field, helping solar, but you can’t take a solar tech and put them in a wind turbine because they got to have the ability to climb safely and understand all the safety equipment.

Now with the GWO standard, it takes us time to get them trained up, but we’re looking at abilities to where the technicians that want to transition between wind and solar is to give them that opportunity and bring them in for the additional trainings. We’re also a telecom company. So we are we’re working with those guys as well.

And we like, there’s not just wind towers. There’s also telecom towers, EV as well. That’s another sector we’re big in. We’re a lot, if not the largest EV service provider. In the market today, and we are actually working diligently with another client of ours and we’re gonna be installing several ev charging stations outside the facility that will actually, the public will be able to use.

But our technicians that come in to get trained, they’re gonna go out there and get hands on. actual operating EV stations. So we do offer and continue to push and to grow the ability to cross train all our individuals.

Joel Saxum: Yeah. So guys, we’ve we’ve talked to a lot of training centers. We talk with a lot of people that are involved in the veterans communities on the, in wind or outside of wind.

But what we hear from them is man, when we get vets in, they’re fantastic. They’re ready to work. They’re used to tough conditions. They’re used to traveling. And most of them come with some technical aptitude straight out of whatever branch they were in. So they end up being rock stars on these renewable energy crews out in the field, whether it’s solar storage, wind, it doesn’t really matter.

How are you guys engaging with that community to help boost up peers?

Travis Dees: We have a recruiter. His name is Frank Martinez. He’s an actual veteran himself. His one job as a recruiter is fully to go find veterans that are either already retired or getting ready to retire and getting them into Pearce.

Like we are dedicated to working with the military. Frank’s an outstanding recruiter. It’s awesome. And I believe To what everybody else is saying, I’m gonna jump on the bandwagon, man. These guys coming out of the military, they understand what it is to be organized, they understand the importance of being part of a team, showing up on time and delivering, like they’re amazing.

And we do up here, we have dedicated an individual, his only job is really to recruit vets that were part of all types of other organizations. That, that are specialized in recruiting veterans straight out of the military, or even those that have been retired that are finally like, Oh, all right, I gotta go find something to do now.

So we’re pinpointing it. We’re finding it. And our COO was given a, an award this year from the veterans for our continued participation in recruiting vets. So that was a pretty cool moment for for our new COO this year.

Allen Hall: Travis, I’m new to the wind industry or an experienced technician.

How do I connect with Pearce Renewables to get enrolled in some of these things and get up and get out in the field?

Travis Dees: Yeah, I think the easiest way to find us is on social media. Facebook, LinkedIn, Instagram, like we’re everywhere. Obviously our website at PearceRenewables. com or PearceServices. com. Either one of them, I’ll take you to the home page.

Allen Hall: So Travis and John, thank you so much for being on the program. The Pearce Renewables training facility is amazing and we will definitely have to come back out and visit it again.