This article by Allen Hall, President, Weather Guard Lightning Tech, was originally published in PES Wind, Issue 1, 2023.

It’s springtime in the northern hemisphere, which means more lightning strikes to wind turbines. Most of the time they can handle the strikes, no problem. But in rare instances lightning does tremendous damage. When asked about a damaged turbine, lightning experts usually respond that ‘it’s force majeure’, or ‘it was a super-bolt™’. Not elegant responses, but the wind owners, operators, and insurers hear it a lot. How did we get here, and what really matters in turbine lightning protection? These are the important questions this spring.

Lightning is often described as a complex, undefinable, uncontrollable force of nature to a combination of Thor, The Flash, and Storm. Everybody loves superheroes, but lightning is not that complex. Lightning is made of air. It’s super-heated air, but it behaves in predictable patterns and is subject to the same laws of physics as the rest of the world. For example, wind gusts can push lightning tens of meters downwind, which is important to consider when designing wind turbines.

What creates this super-heated air we call lightning? Well, that is complicated. Lightning is the result of opposite electrical charges trying to reach an equilibrium. Clouds build up charge through friction of ice particles that eventually separate into positive, generally towards the top of the clouds, and negative, at the bottom. The difference in charge becomes so enormous that the air begins to transform from a non-conductive medium to a chain of conductive molecules. This process can continue for several kilometers.

Lightning strikes can occur within a cloud, known as intracloud, between clouds, referred to as cloud-to-cloud, cloud to outer space, sometimes called sprites, jets or elves, and cloud to ground and vice-versa.

Cloud to ground is the most common type of lightning seen in nature, hopefully from a safe distance. Lightning can be both positive and negative, and standard convention defines the polarity by whatever charge the cloud is. Wind turbines and other tall objects also fall into unique sub-categories of lightning; triggered lightning and upward lightning, that give wind turbine designers sleepless nights.

Why does the type of lightning matter to a wind turbine? Cloud to wind turbine downward lightning and wind turbine to cloud upward/triggered lightning contain different quantities of energy, varying bursts of current, and wildly different durations. Polarity also matters. Most strikes are pushing negative charge into the wind turbine, but positive strikes tend to be the most powerful. What is there to do?

IEC 61400-24: International standards are great, sometimes

Let’s focus on the main lightning issue with turbines, the incredibly long and complicated composite blades. Replacing a lightning-damaged blade can easily exceed $1MM, depending on the blade type, availability of a crane, and remoteness of the site.

In their infancy, wind turbine blades were simply a couple of fiberglass epoxy shells with a balsa wood core. And the early blades were miniscule compared with the 100m long monsters of today. A thick copper cable was routed inside the blade and a metal cap or aerodynamic tungsten bolt was mounted externally a la Ben Franklin’s lightning rod. It’s remarkable, but some OEMs didn’t put any lightning protection into their blades at all.

It took a couple of years in the field to realize that wind turbine blades were being attacked by lightning. News photos of blades split in half by a strike were common. Insurance adjusters were frustrated, and OEMs were pressured by operators to stop the madness. Something needed to be done.

That’s when the OEMs headed to lightning laboratories to get answers. Those answers mainly came from the aerospace world where, 40 years prior, government regulators stepped in to create a legal framework to validate aircraft lightning protection. Wind turbines and aircraft are not exactly the same, but the process to validate an aircraft lightning design could transfer over to wind.

The wind industry has placed its collective wind turbine lightning knowledge into IEC 61400-24 ‘Wind Energy Generation Systems, Part 24: Lightning Protection’. Weighing in at almost 200 pages, it’s designed for the engineers, with plenty of technical graphs and complicated formulas. Great reading for insomniacs.

Lightning Damage to Turbine Blades: What are we missing?

The IEC specification has useful test methods to evaluate the basic lightning protection in blades. But there are several sections which are more palm-reading than predictive. Estimating the number of strikes a turbine will take or calculating the risk of lightning damage are not numbers to bet the farm on.

Every wind farm is different in terms of the probability of lightning strikes and damage. There are far too many variables at play to be processed by a spreadsheet. As wind turbines increase in height the quantity of lightning strikes to a turbine will naturally increase, regardless of the industry specifications. Upward lightning strikes will also originate at the wind turbine. In essence, the presence of taller wind turbines will dramatically change the number of lightning strikes in that region.

The more recent move to test blades in the lightning laboratory has generally reduced lightning damage, just not enough in comparison to the vast number of wind turbines that are being deployed. Lightning is usually a top 3 problem for most wind farms. Why hasn’t testing, which now includes the use of computational analysis, significantly driven down the lightning related costs?

Since the 1930s lightning researchers have been photographing and measuring lightning strikes to tall buildings and towers. GE measured strikes to the Empire State Building in New York during the 1930s and 40s, and much of the data is still used today. Years of subsequent international-led research, mostly conducted on large towers, added to the collective knowledge. This research yielded the basic definitions that are used in the IEC specification today.

Data from actual strikes to turbines in service indicates most of the damage is caused by rather ordinary strikes. The data also shows that blade punctures are not directly related to the amount of lightning current or energy in the strike. And the electrical resistance of the blade’s lightning protection system is generally not critical. A few extra milliohms in a Lightning Protection System (LPS) bonding measurement are, almost always, not worth addressing. High value LPS resistance, 1 ohm and higher, indicate the LPS is weakened or broken. Indeed, the engineers at Aerones have found more than 20% of LPS need repair. This needs to be addressed, quickly.

What are the lightning engineers missing? Laboratory testing doesn’t accurately represent strikes to moving blades. In fact, lightning labs can only recreate select snapshots of a lightning event, the high voltage lightning attachment, and the high current physical damage. Both tests, however useful, are conducted with pristine short-length blade sections which have a much better chance of passing the test. Blades exposed to years of service don’t fare as well as a new blade.

During these lab tests, the blade sections are stationary; there is no airflow to represent a moving blade. Since lightning is made of air, the flow of air across a blade would alter the test results.

Blades also create a large charge cloud before a lightning strike, in opposition to the charge stored in the clouds above. This charge cloud surrounds the area around the lightning receptor(s) and changes the pathways that lightning will travel to the blade. Researchers from Asia, the US, and Europe are beginning to simulate and model this process. Initial studies predict that tip speeds alter the shape of the charge cloud and therefore the resulting lightning attachment location.

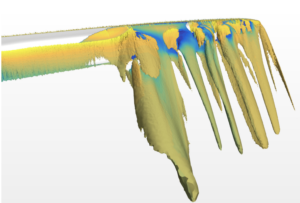

Today’s turbine tips have speeds approaching 350 km/h. Once lightning attaches to a blade, it must hang on to the blade’s tiny lightning receptor for up to 100 meters. When the leading edge has erosion or contamination, the airflow becomes incredibly turbulent. This effect increases the likelihood of blade damage because lightning can’t stay attached to the receptor. PowerCurve ApS in Denmark has conducted numerous studies of this effect. See the computational fluid dynamics graphic here.

How to minimize lightning damage to wind turbine blades

What can be done in the meantime to reduce lightning related headaches? Detecting lightning damage early dramatically reduces the final repair costs. Simple steps like installing a low-cost lightning detector and blade damage detector from Australian-based Ping are a good start. Lightning detection units that measure lightning parameters can be helpful and are available from Jomitek, Poly-Tech, Phoenix Contact, and many others. Vaisala’s lightning detection network is also widely used to identify potential strikes to turbines.

The LPS resistance also needs to be validated every two to three years. A broken connection in a blade can act like a hot torch near the composite structure, setting it ablaze. While qualitative resistance measurements can be made using a generic two-wire resistance meter, the most reliable measurements are produced by four-wire resistance test sets. LPS resistance generally increases with age in a predictable pattern. Large jumps in LPS resistance should be investigated.

Finally, updates to the basic blade LPS can reduce the repair budget. These updates must be able to survive harsh erosion at the blade tip. They include adding a metal tip or metal tip sleeve, installing segmented lightning diverters, or bonding metal straps or mesh to the blade exterior. Updates generally occur during blade repairs or repowering campaigns.

The next decade will bring additional challenges to lightning designers. Thunderstorms in offshore waters have not been researched extensively. Newer offshore turbines will generally exceed 15MW, with tip heights approaching 300 meters, nearly the height of the Empire State Building. We might need another 1930s style lightning research revival to instrument these massive offshore turbines to move the industry forward. There is much more to come.

# #

For reprints of this article, or to discuss better blade protection, contact us.