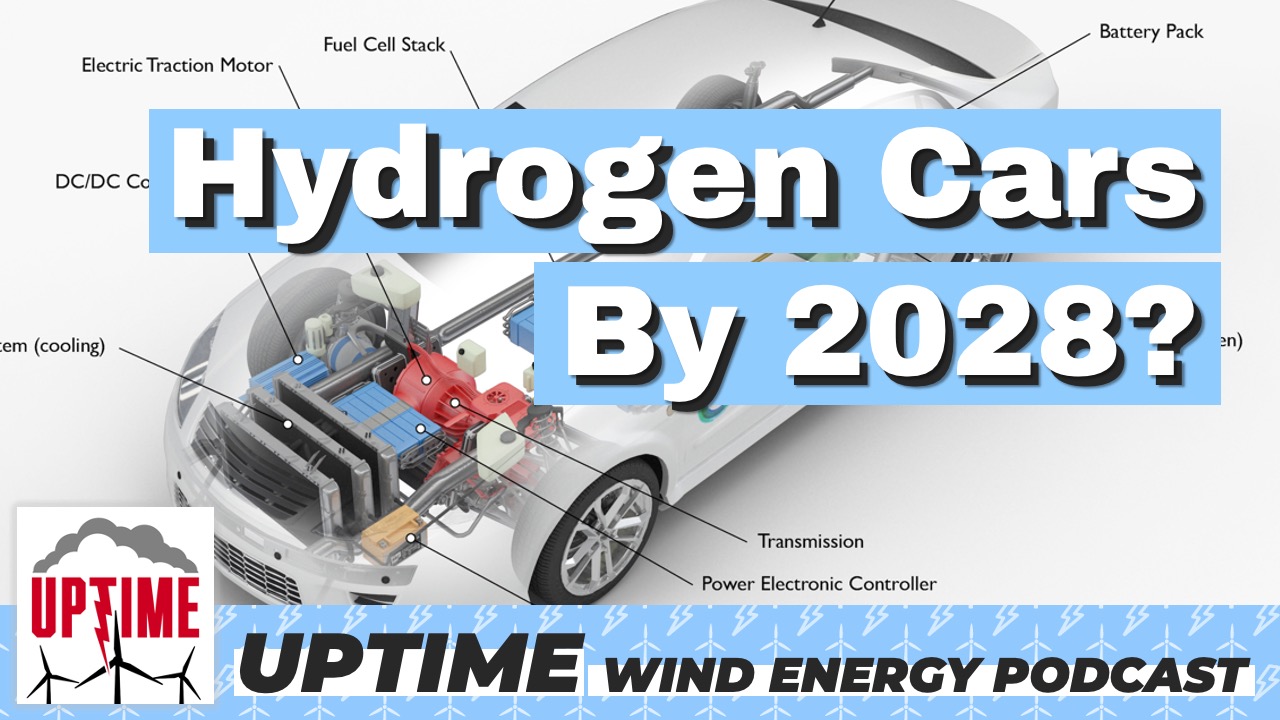

Hyundai has pledged to create a hydrogen-powered version of each of their commercial vehicles by 2028 – is this realistic? Is it necessary? OEMs are reporting increasingly thin profit margins on wind turbine sales – can they improve profitability somehow? Plus, ComPair healable composites and the Siemens Gamesa RecyclableBlade is announced.

Podcast: Play in new window | Download

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Transcript: Hydrogen Cars by 2028? And, Can Wind Turbine OEMs Turn a Profit in 2021?

This episode is brought to you by weather guard lightning tech at Weather Guard. We make lightning protection easy. If you’re wind turbines or do for maintenance or repairs, install our striketape retrofit LPS upgrade. At the same time, a strike tape installation is the quick, easy solution that provides a dramatic, long lasting boost to the factory lightning

protection system. Forward thinking wind site owners install strike tape today to increase uptime tomorrow. Learn more in the show notes of today’s podcast. Welcome back. I’m Dan Blewett

I’m Allen Hall,

and I’m Rosemary Barnes,

and this is the uptime podcast bringing you the latest in wind energy, tech news and policy. All right, welcome back to the Uptime Podcast. I’m your co-host and blew it on today’s show. We’re going to talk about right off the bat, hydrogen news.

So Hyundai is pledging fuel savings, fuel cell versions of many, if not all of their make some models by 2028, which is going to be an interesting engineering challenge. We’re going to talk a little bit about the overall state of renewables as it comes to sort of one drivers, the other that seems to be a lot of

infighting on the Web. Of course, that’s what the Web is for, it seems like at times. But we’ll talk a little bit about, you know, this whole sort of war on renewables and who’s best or if we can all just kind of get along.

We’ll chat a little about distributed wind. And interesting article from the United States Department of Energy, just highlighting some of the different uses here in the U.S. of distributed wind. We’ll talk about winter manufacturers who are maybe getting their profit margins squeezed a bit as raw material and other costs rise.

And then we’ve got a bunch of interesting composited news. Talk to a bunch about that last week. But some more here with Compar has this self healing composite. They’re a start up and they’ve got some interesting tech, some interesting belayed techs or some interesting blade rotor size designs.

And then some big news from Siemens with their recyclable blade technology, which almost a little bit seems to fly in the face of some of the other stuff we reported on last week about thermostats and reusing them. So before we get going, just want to remind you and no.

One, you can sign up for uptime tech news in the description of the show, whether you’re on YouTube, Spotify, iTunes, Stitcher or wherever. And that’s just our weekly email update. We all get the new show in your inbox along with other great renewable and wind energy news.

And definitely check out Rosemary Barnes. Our other co-host, try host. What are you going to call her? Her awesome YouTube channel in the description below. So, Rosemary, let’s start with you. So Hyundai is interested in hydrogen fuel cell versions of all their cars by 2028.

You’re our hydrogen guru here. Does this seem like a reasonable step? I mean, that’s only six years away. And I don’t we don’t have any hydrogen cars on the market.

I was surprised when I heard that. I think that they do actually already have a hydrogen SUV. I read that anyway, only learned that while I was researching for today’s podcast. So maybe they’ve got a little bit of a head start.

But I was actually really surprised because most of the other manufacturers, you say pushing hydrogen cars are ones that don’t are aren’t known for having really good electric cars, whereas Hyundai does that. Ionic has really good reviews. I mean, it’s it’s one that I’m I’m in the market for a new car sometime in the next few months

. And it’s definitely on my list if I can get it in Australia. So, yeah, from that point of view, I was surprised. But on the other hand, there are a South Korean company. I know that the the government there is really pushing hydrogen.

So in that sense, it’s a bit like what we see in Japan where, you know, it’s it’s likely to be strongly government backed or the infrastructure and stuff that you’ll need for it. So maybe that makes sense.

Juan, is there going to be I mean, what’s the big advantage like? I don’t feel like we really even settled in to electric cars. You know, my family. I don’t drive a car since I live here right in the center of D.C. But you know, all of my immediate family, none of us own electric cars.

I’m yet to an electric car. Alan Gionet, any electric cars?

No, not at the moment.

And is this seem like a big. It’s like we haven’t even settled in there yet and yet we’re already moving on to the next thing. I mean, what kind of infrastructure, Alan, would it take to have refueling? And like I mean, what is this going to look like?

We’ve talked about this on the aircraft side on our other podcast called Struc. And you just talk about how big of a change you’re going to have to have in the fuselage. Like every little bit of the airplane is going to be just a massive engineering challenge.

Is it? It’s obviously going to be easier for for vehicles. But I mean, how big of a challenge is that?

It’s a big engineering challenge. And I think Honda and GM both have had hydrogen cars in the United States. I do think I can still get access. And in California, I think you can still buy the hydrogen based Honda.

But the problem is in the states, where are you going to refuel it? Right. There’s only a limited number of fuel places on hydrogen at the moment. And the engineering challenges in the car itself are a lot more than putting a couple of batteries in an electric motor in.

So you got these complexities with the hydrogen in the car itself that you have to design around, and then you have to create the infrastructure. And Tesla has pretty much squashed hydrogen in two thousand and eight when we had the economic collapse and the federal government actually owned the majority stake in General Motors.

Now, that was one of the discussions, because GM and some of the car manufacturers had already sort of progressed into hydrogen and they were told to stop. Right. So in the United States, those car companies just told hydrogen hydrogen’s never going to happen.

We’re going to go electric and battery power, which then changed the way the marketplace exists in the United States. And Tesla took full advantage of that. Right. So Tesla installed thousands of recharging stations across the country. So now hydrogen, which has a lot more infrastructure involved, can’t really catch up.

In the States, it would take a good, solid 10 years, I think, to get to the point of having hydrogen everywhere and be able to generate a truck at around or whatever is going to do. I think that’s over.

Right. So I’m I’m curious why on the other side of the world, hydrogen is really still being considered. Rosmarie, is it being considered in Australia at all for normal vehicles?

Still a little bit. And you say a few trials, two years, hydrogen for home heating as well in Australia, which is the weirdest thing, because we’re the last place that that struggles with challenges facing eight months for hading.

So very strange. But what Australia really wants to do is sell hydrogen to these countries. So, yeah, when you look at the markets that we’re signing, you know, deals with or I don’t know, whatever comes before ideal. It’s like Japan and South Korea, mostly countries that don’t have a lot of capability to to make a lot of

renewable electricity themselves. So that’s why, yeah, those countries, I think, are really pushing the hydrogen from the government level. Yeah. And I think that that is the only way that it can can work for passenger cars, at least because I mean, you say electric cars have a head start, but even if they were both starting on the

same point, I think that there is a bigger, bigger initial hurdle for hydrogen cars to face, let alone the inefficiency of using hydrogen as a fuel instead of electricity. And then there’s the consumer side, too, I think, because like if I am looking for a new car and one of my big constraints is that usually when I’m

driving, I’m driving a long way. I’m driving to go surfing at the cars. I’m driving to the mountains to go skiing or mountain biking. So I am I do have a bit of range anxiety, but when I think about, yeah, hydrogen, it’s worse the riding side, because I’ve got a I can only go places that have a

, you know, a feel a hydrogen fuel station. It’ll be a long time before we get that network out. And electric cars have the advantage of you never have to go to a petrol station midway, you know, you just charge at home for your daily commute.

And I just think that for passenger cars, like out of all the things you could do with hydrogen passenger cars, is the least likely to kind of win.

Well, Rosemary, what’s what’s the advantage like? Why should people care? Like, you know, like electric is different than gas. It’s completely different. Right. But like, why should I care that my car burns hydrogen or, you know, I don’t exactly know how a fuel cell works, but why should people care that they use hydrogen versus electric?

Is it going to be faster or is it going to be cheaper? Is it going to be better for the environment? Like I mean, what is the selling point and how are people going to say, oh, yeah, I’d rather have a hydrogen car than an electric car?

I guess they’re going to be a big difference in any of those sort of key factors?

Yeah, I think so. And I think also, I mean, people have been developing hydrogen cars for decades. I think, you know, maybe 10, 20 years ago, battery electric cars hadn’t got any any kind of reasonable range at that point.

And so hydrogen seemed like. They way to de carbonized passenger car. So I think that’s kind of how it started. And now the main the main selling point for hydrogen is that it is the range like the amount of time kilometers that you can go in between fueling.

So, you know, you could still drive a thousand kilometers between stops at a petrol station or a hydrogen station, which is, you know, like really similar to internal combustion engines. So I think that that’s that’s the main thing.

But, you know, hydrogen takes up a lot of space. So if you look at like actually comparing to equivalent cars and you’ll usually say, you know, slower the hydrogen fuel cell car probably be a bit slower than the electric one and have a bit less storage space in there.

So less range or less less speed, less storage space. Sign me up. Sign me up, guys. Like a kind of like a small convertible.

Yeah. More more range, but less everything else.

Yeah.

OK. In in general, although if you look at actual examples like the main hydrogen car that anyone actually has now is the MERAI. And that doesn’t have such a such a great range. I can’t remember what it is on.

Off the top of my head. But yeah, it’s. Yeah. I mean, I don’t believe in hydrogen passenger cars, but some some people do, obviously.

Yeah. And that’s I mean, we talked about the lyrics, hydrogen letter. And so going back to that, like you just wonder where like is this something that we really need to do or is it just something that’s maybe pie in the sky or maybe not maybe not economical?

So moving on. Speaking of costs and just all these engineering challenges, offshore wind costs are rising and it looks like it’s getting tougher and tougher for some of these OEMs to turn a profit and make a buck, even though obviously there’s a huge offshore boom globally and specifically here in the U.S. with the new administration.

Alan, what are some of the struggles that these OEMs are facing and why are their profit margins being trimmed so thin?

Well, I think the manufacturers got burned in the states not long ago. And some of the exchange rates, combined with material costs, combined with governments fluctuations on whether they’re going to permit turbines to go in. And there was an interesting podcast by Siemens, put out a maybe a month or two ago where they were talking about the

offshore opportunities and wind and saying in the United States, the marketplace is huge, but the ability of the OEMs to manufacture the number of turbines in the short amount of time is really there’s like a 10 percent chance they’re going to do that.

So they are being very hesitant in the United States on offshore wind just because the economics there’s not enough of a profit margin. Remember, a lot of these large industrial companies are working on two to three percent profit margin.

It doesn’t take a lot to blow away three percent. And you’re in the negative, right? And then you’re the company can’t function. So they’re very careful about where they put investment money in. And I’ll give you another example was that I think I was L.M. that’s going to build a facility in Teesside, UK, which is GE and

Elm. We’re going to build a blade manufacturing facility in Teesside just for the offshore wind off the U.K. That’s a huge financial investment. And that’s just in the U.K., which is a much smaller marketplace than the United States.

So you can imagine in the United States, a company like Siemens or GE would could invest hundreds of millions of dollars in facilities easily to support wind. And if if the administration changes the United States and if the economy tanks, you could collapse a Siemens.

Right. And that’s the struggle. So they’re going to be extremely cautious going forward. I think financially they have to be. So you want to basically book a sale, get the money, the bank, then build the turbine. That’s the ideal they want to get to.

They don’t want to be floating your money and wait for the the government to change in Massachusetts so you can’t put offshore wind in. They want to have a confirmed order and payment for that turbine before they build it.

I think that’s the way they’re going to approach it. So this is going to be a totally different economic structure than maybe has been in the last 20 years, like in Texas or Iowa, where you’ve had large, massive financial companies involved in the development process.

I’m not sure offshore wind is going to have that same sort of thing when it really gets going, particularly from the OEM side. And Rosemary, I know Australia’s going to be in one of those places and you’re part of the world.

Is it going to be a lot of offshore wind? Are you seeing the same sort of economic turn? In the end, the conservative activism towards offshore wind from the OEMs

were way behind Europe and the US in terms of offshore wind. We’re still just at the stage of talking about it. There’s definitely one, that one. Projet it looks like it’s going to going to happen, but it’s still, you know, I wouldn’t bet money on it actually actually existing and it won’t be towards until towards the end

of the decade. But that’s as much because we have so much land available and we have a bit of a challenging offshore environment to the you know, the shelf drops off quickly. So it’s there’s not much opportunity to put them in shallow water like the early wind farms have been in Europe.

So I think it’s a bit early to say if we’re going to face some similar. Yeah, I’ll be surprised if we get much wind turbine manufacturing in Australia, but we do have some really huge like land based projects in all those, though, what they call keigo giga projects in the the desert.

I mean, there’s so much volume there that it might make sense. But I think you’re so right when you say about like a wind turbine manufacturer doesn’t want to just build a factory in and and hope that the market develops, they really do need a strong pull to get in there in the form of confirmed orders or

governments often give really, really attractive incentives to get, you know, factories into regions that need jobs. So I think in Australia, it’ll be the same without without really compelling reasons. They’re going to they’re going to build them where they.

Well, they already can.

I want to switch gears a little bit, so there was an interesting article from WHINSEC International about super large rotor blades in the sort of development pipeline are really more just sort of like in the prototype pipeline, if that’s a thing.

And we’ve talked about blades getting longer and longer. We talked about the new six megawatt offshore turbine by Mingqiang or recently by Rosemary. Where are we going to start to see these rotor blades, especially when they hit this sort of quote unquote, super large status?

Are they going to start to run into additional problems?

Yes, I was just thinking it’s a little bit similar to maybe five or 10 years ago where we keep on getting these, you know, announcement after announcement of the world’s longest world’s largest, you know, whatever. And I think the the thing to note is that it’s really easy to make an announcement.

It’s not like, you know, we’re in the Guinness World Records where there’s a set criteria for what it means when you can say, I have the world’s longest wind turbine. Right. So I think that, yeah, everybody wants to announce something like this.

But to me, I mean, until you’ve got a wind turbine blade design that somebody has bought. I don’t really think too much of it. I mean, I couldn’t give you a 250 meter long by design. By the end of the day, if you wanted to make it announce that we have the world’s longest blade.

But, you know, unless unless it’s a real commercially viable thing, I don’t really pay that much attention to it.

No, I think it’s very comparable to what happened in airplanes not that long ago, which is the largest passenger plane was the Airbus 380. And now they’re not making it anymore because the costs are so prohibitive. And the same thing on the fastest commercial airline, which was the Concorde.

And that didn’t last very long. I think they made 10 of those. So the economics really play into what products succeed and what’s don’t. And you can make blades much longer. But there’s a lot of costs involved with that from the tooling to the to them, all the materials to the added stronger fibers.

When you talk about using a lot of carbon fiber in it, and then you have while you have lightning protection issues, you just run the gamut. And at some point, it doesn’t become economically feasible to even do it.

Even though you could announce it, you wouldn’t want to do it. And the wind turbine industry, I think they’re full of really smart economics. People that are looking at the cost of manufacturing, this turb and the cost to get it to the site, to Geiss, to install it, to cost to repair it, which could be astronomical, the

cost of something collapsing, all those play into that economic model. And I think the energy industry has done a much better job than the airplane industry of sort of predicting those things. So if the airplane industry will stumble and make 50 Airbus 380.

Yeah, OK. You know, Airbus will be around tomorrow. But if Vestas makes a 200 meter long blade and it goes catastrophic, somehow Bastos could be sunk. Right. And that’s that’s the difference is that they’ve got to be really careful about the economics and the risk they’re willing to take versus the potential marketplace.

I don’t think you’re going to gain that much marketplace, honestly, if you made another blade, another three meters long. And I guess another point I want to keep. I don’t think anybody cares versus the downside risk, but I got to go fix this thing that that’s where I think these blade press releases don’t make any sense because

it doesn’t really drive the marketplace.

Or can they I mean, can they announce like so say, you know, energy tech announced a new wind turbine in a year and it wasn’t bigger, but it was just better? Well, like, where can they get better without getting bigger, I guess is my question.

They’ll get they can’t continue to get bigger forever. So like what would be the cool announcement that they would make where it’s like, hey, we made a blade that’s only 98 meters long, but it’s awesome. Here’s a couple of reasons why.

I mean, Rosmarie, what could they do to make better but not bigger?

They can make it cheaper. That’s that’s basically what everybody’s everybody’s trying trying to do. I mean, no one’s really trying to make the world’s biggest blade except for maybe marketing departments like that. Everyone’s trying to make the world’s cheapest kilowatt hour of electricity from a wind turbine.

That’s that’s all we’re all trying to do there. And then the other things, I mean, there’s there’s noise as recyclability. There’s danger to wildlife, visual impact. These are the things that people care about. And yeah, I mean, if you look at any ad for a small wind turbine or any, you know, like really weird out there, wind

turbine concept, these are always the points that they hit. Those are the perceived downsides to the utility scale turbines. But honestly, I don’t see most of them changing too much except for the the cost. And yeah, it’s always it’s always the cost.

The answer is always cost for nearly every question you ask about.

Wind turbines got it, well, that’s a good lead in to distributed when so I mean distributed wind is. It seems like it’s picking up speed, but it’s still not as widely used, I guess, worldwide as it could be.

We had our friends from use like on the show, I guess about six months ago now, and they’re excited about the industry. But, you know, there’s law says this interesting article from Energy dot gov, which is the U.S. Department of Energy, that there’s 87000 wind turbines across the 50 states here, at least here in the U.S., Puerto

Rico, Virgin Islands and Guam. And that from 2003 to 2020, the cumulative install capacity is about a thousand megawatts. So that’s not a lot. But it’s certainly something, Rose-Marie, I mean, it seems to me like distributer wind could be like a cool sort of like minor leagues where they test a lot of stuff out and maybe new

tech start small and goes bigger. But it doesn’t seem like that’s that’s the way this works, does it? Because it seems like they’re very different. The blade structures are very different. I mean, where do you see that? Is there a trickle down from big to small?

Is there a trickle up from small to big? I mean, how does how did the distributor wind and an engineering of big wind interact if if at all?

I have a few videos in the pipeline and my first live stream is going to be on this topic because people are so interested in distributed wind. And, you know, they they love it. They’re really enthusiastic for it.

You can put solar panels on your roof. People want to put a wind turbine on their roof or in their backyard. But I mean, to answer your question, they’re totally separate, in my opinion, the small wind turbines versus the large ones.

I don’t see any kind of technology transfer between them, any the small wind turbine market. It’s like a cowboy industry. There’s so much misinformation out there. And my big piece of advice for anyone who wants to get into it is to look at the certification as a couple of different bodies that are certifying small wind turbine blades

and testing their claims. And so get a turbine that’s been certified if you’re going to get one, because otherwise you’ve got no clue what you’re going to get. Yeah, but basically the the number one downside to distributed wind versus, say, distributed solar is that the wind resource in urban environments is is much worse than what it is

in, you know, the kind of locations where they put utility scale wind farms. So in urban environments, you’ve got heaps of turbulence, you’ve got low wind speeds. And remember that the power in the wind, it changes with the cube of the wind speed.

So if you double the wind speed, you have eight times as much power in it. And that’s why we see large wind turbines, that the towers are getting taller and taller. They’re going to all the effort to put them offshore because that’s where really great wind is.

So urban winds the opposite. It’s nice and we can make energy, but I don’t think we’ll ever see really cost effective wind energy from the the distributed environment. So it needs to be done by others. And so if you’re going off grid, if you want an engineering project to tinker with, if you.

Yeah, I guess those are the those are the main the main things. If energy independence is important to you and you like the look of distributed wind, then that’s the people that it suits.

In my area, distributor, Windows Band, our town and local communities have actually prohibited wind turbines within the town limits. And that is not unusual in the Northeast because of sightlines lines to the mountains or sightlines to the ocean.

So the the the wind projects, the smaller wind projects have essentially stopped unless you’re out on a on a farm somewhere. The solar projects continue to happen because there’s massive incentives in my area to to do it. And they’ll come and install solar panels on your roof and all is great.

But the wind turbine side has been really quiet. And I think there are still in the United States because of the the landmass and the three hundred and thirty million people, there’s still a viable marketplace for for smaller when projects to take place.

And I do think there will always be that a niche market there in a profitable market there. But the the lessons learned between large wind and small wind are totally different. Right, because you just the structures are different the way they’re built different.

The what the what they need to provide is different. And so I don’t think you have seen any cross development there. I think the places where it makes sense are places like islands, islands, which have limited resources and can use smaller wind to run generators or to provide pumps or whatever for for water.

Those things make a lot more sense than sort of in an industrialized society where there’s electricity freely everywhere. Small wins going to have limited spaces where they can.

Participate, yeah, well, and as Paul dorsum from either cycle, who was our again, our former guest, he was saying that, you know, in the Midwest, where there’s medium sized farms and there’s some small businesses out there where they do have good wind, you know, it might make sense for them.

But you’re right, it seems like it’s a complex issue with just urban areas where, you know, like you said, sight lines were like northeast would just be a really complicated place to put one. I mean, you could definitely see that, not to mention the land is so expensive.

Not like you’re using it up. But yeah, just just lots of different costs compared to somewhere like the Midwest, which probably is a really suitable place where at least here in the U.S.. But yeah. And we’ve talked about some of the just the structures of blades.

How many men don’t have a lightning protection system or don’t have a real need for their solid blades? Right. They’re not they’re not hollow like the commercial sized ones. So anyway, interesting, interesting stuff by the Office of Energy Efficiency and Renewable Energy, because it would be cool to see that sort of fill in and just be a

bigger market in the U.S. And I don’t know, maybe it’s some of the cost will come down from the trickle down effect, even if there’s not a lot of shared shared engineering. Who knows? But. So moving on, Compar is a spinoff company and they are developing a self healing composite material.

So what they say is there’s a quote from their CEO with our technology repair agent is incorporated in the composite material. Cracks in the resin can be repaired on site, the heat, the the material to moderate temperature and then activates the repair agent and then the damaged part will hear will heal.

So, Rosemary, you’re one of our well, two of the three of you are composites, experts. But Rosemary, I’ll start with you. Is this sound like pretty revolutionary thing? Is have we had any version of this in the past or is this completely new?

Is self healing technology?

Oh, I don’t think it’s completely new, because, I mean, if you’re ever using a thermoplastic resin, then you can heat that to and reset it. And I actually couldn’t get I assume that this is plastic as well. So I didn’t from the information that I saw, I didn’t say anything revolutionary in it.

Maybe there is. And they’re keeping it a secret. It’s possible, but yeah, it only fixes cracks in the resin. So I don’t I don’t see any wind turbine blade repairs that involve only a crack in the in the resin.

That’s not like a that’s a very small damage that you probably wouldn’t even notice. So I don’t see a huge application for this in to change anything much in wind turbine blades. But, you know, some of the other things, like a car bumper, for example, you’re constantly probably having like small bits of damage to your car bumper

and yeah, you go hate it up and repairs itself, that sort of thing. I think it could be pretty cool for Allan.

Is it something that could start small and grow bigger over time? I mean, a lot of these, you know, little breakthroughs might not have a lot of applications early or just very specific ones, but then maybe grow generally as as a candidate for that or.

No, I think this kind of technology, which there’s been different variations of this for in aviation discussed for the last 20 years, aviation and wind energy are not the places to start. I think there are a lot of other industries in which this makes sense.

Small boats, for example, things that are you know, if you’re

sinking, you can just heat it up and you stop thinking that would be awesome.

Yeah, I mean, we both get dinged all the time. Right. So both getting all the time and they’re expensive to repair. So, yeah, you’re not going to sink the boat, but it would maybe save you of money on the repair side.

So those are the places where this industry needs to grow. It goes back to my big complaint about composites and plastic makers and the whole thing. Your first article is not on airplane. The first article is not a wind turbine.

Your first article, maybe a skateboard. Let’s let’s start off as as minimal as we can get and figure out the technology, because that’s where everything else started. Right. We didn’t get to aluminum airplanes without going through a huge development cycle.

We we’d still be making them out of wood unless World War Two happen. And so it takes time to develop the the the the technology before it gets involved in something as critical as me flying in an airplane.

I do not want to be in an airplane with a lot of new technology. I want that technology to be been like home for 20, 30 years before I step on an airplane. I think the same thing exists in wind.

Let’s take a step back. Let’s yank the marketing guy out of the discussion and stop issuing press releases and say, hey, look, we can make money in eight different markets. We don’t need to be in wind and be upset or a game changer or whatever kind of lingo is being thrown out in the marketing world right now

. You don’t need that as a business person. You need to start small, figure out where the marketplace exists and kill it in that marketplace. And then you can expand your horizons, but at least get the small stuff right first.

Have you ever seen a skateboard crack, though? One’s on like jumps it off like a ledge. Down some stairs they crowded and I mean, you need to be trying to skateboard, skateboards are actually pretty impressive, little pieces of art, of craftsmanship.

There’s a lot of technology. And now you’re saying you wouldn’t fly in the Spruce Goose if we could revive it somehow. Are you saying you wouldn’t be in that thing?

No. Well, I’ll give you the good example. Right. So there’ve been a lot of like. Right. Fliers being rebuilt because of the you know, in 2003, it was a 100 year anniversary of the Wright flier. So there was a lot of projects to rebuild the Wright flier and a lot of them resulted in big crashes.

So unless you’re really familiar with the material, there’s a difference between spruce that was made in nineteen oh two in 1893, then spruce up made in twenty, twenty, twenty.

What do you mean made what do you mean made. These are trees, Allan.

The trees are totally different. No, they’re not. Well, they’re not the same. Not the same. They’re not the same. Right. The woods are different. The way they respond is different. The technology. And that’s the people. The people that can handle that stuff and manufacture it and know how to process it are totally different now than 1915 when

they’re making fifty thousand airplanes out of wood. That’s a totally different thing. And I think it’s not just the material and how cool it is, but it’s also how it gets integrated into the larger stream of processing, maintenance technicians touching it.

All that which gets gets overlooked is where the failures occur. Because one technician I’ll give you a simple example here on the repair side. If I was supposed to heat the maturer up to get the repair to happen, what happens when I’m a technician gets it too hot?

What happens? I mean, if you’re going to let him get it hot. They’re going to get it hot. If they get off the overhead, do they just ruin the whole structure and not even know? Right. Because what’s going to tell them they overheated it.

Right. Those kind of things are real situations that happen all the time. And if unless you build in those failure modes into the design of that product, you can have big accidents. And I think the technology is cool, but you have to look at how it’s going to be used and what what the downstream applications are.

And a lot of times that doesn’t happen.

That’s interesting. Also, I’m glad we’re filming remotely because I feel like you angered Mother Nature just now and she’s going to strike you down with a lightning bolt. Well, thankfully, many miles away from here, so. OK. And Rosa Parks, if she says she’s she’s safe.

Yeah, the lightning guy. Yeah, I would take the fall goes down. Yeah. Well, moving on isn’t as I think our our big discussion here is Simmons Camus’s new announcement about their recyclable blade. And I think they missed an opportunity here to call this recyclable aid.

But, you know, I digress that they are basically saying that they’re ready to do some of the things that Vestas was sort of announcing that they’re purporting to do when it comes to, you know, fine tuning some of the recyclable aspects of winter and blades, like we talked about thermostats and how they’re not quite maybe ready to

be reused again. So Rosy, we’ll start with you. Recycle Blade. What’s what’s the story here? What what sticks out to you about this announcement from Siemens Gamesa?

Well, yes, I mean, it does sound like it’s ahead of some of the other recyclable blade projects we’ve seen where they have earmarked some some blades that are going into a new natural wind farm. I think it’s not all the blades for the wind farm, but just a few of them, which is smart, I guess.

Stop, start small. So from what I could gather, it’s a new new resin kind, I assume still a thermostat resin. So they’ll have, you know, those good structural properties. And then when it comes time to recycle it, they’re going to dissolve the resin in an acid solution.

They’ll recover the fibers that way and use them in other applications. And the applications I mentioned were a little bit lower grade structural applications like like in automotive, a commonplace would be like bumpers or dashboard’s. Hmm. It wasn’t they didn’t say anything about reusing the resin.

So my interpretation is that probably the resin isn’t being reused. So I mean, I don’t know if that’s true, but if that’s true, I think it is a stretch to say that it’s 100 percent recyclable because, you know, resin makes up like a very large, large percentage of the blade.

But, yeah, a new way to recycle fibers. That sounds like it’s closer to execution than the other projects we’ve been talking about. So that’s that’s exciting.

Well, you know, if these recyclable blades go out now, we’re not going to know if this works for 20 years. Right.

I assume they did tests. I should think so. They know

they’re just like, hey,

this works and we’ll figure it out. And we got two decades to figure it out.

Yeah, I’ve made a play. I think I’m going to be able to recycle it, but I’m not going to try. I’m just going to put the flight up oven. It’s for the next 30 years, and then I assume it’s going to work out fine.

I hope that the the testings and panels I hope I’ve already tested some panels and I assume they have if they’re prepared to say that they’re going to build some in the next years.

Well, I want to see them just, you know, like how you can throw packing peanuts or some versions of packing peanuts and water and they just dissolve. That’s what I want to see. You just like hold a blade and just like dip it in and just gone.

Like put it somewhere where it doesn’t like boiling cauldron.

Yeah. Yeah. Good point. Alan, what stuck out to you about this?

Well, I was watching the or E catapult discussion about blade recycling and the different variations. There are two blade recycling, and I may be the lone American sliding into the discussion because Oary is really focused on the UK, but whatever, it’s open to the public.

So I’m at least one of the public. So I like listening to what they have to say, because I think the UK is doing a tremendous job right now on winterman development technology. But that discussion with Oary Catapult brought investors, brought in Siemens, brought in a bunch of other engineering experts, and they were talking about this, a

thermal set epoxy system that would break down in an acid. And it was talked about in the theory side still, which was weird. And literally the next day, Seimas Kummetz announces, we’re already doing this and it looks like it’s going to work and I’m going to start producing blades with it, which is shocking because my gut feel

out of the catapult discussion was it was still maybe five, 10 years off in terms of really coming up with a system and ecosystem to use the material, to process the material, to recycle the material, to find places to, you know, break it apart and send off the constituent pieces to recyclers or reuse people.

So I’m a little and also seamers. Comesa made a point of not announcing who the manufacturer of the of that thermal set is. Who is it? Is it Olwyn? Is it one of the five or six different manufacturers of thermal sets that are around today?

Who was doing this stuff? So it’s still a question mark in my mind. And I don’t know if Seimas Comesa is using this as a marketing advantage for the time being to allow them to put their foot in the door in places where they are struggling to get into vessels is clearly the leader in a lot of

places and wind turbines, particularly in Europe. So but the thing which has got to do something to sort of penetrate that bubble, maybe maybe this is it, because there seems to be a lot of oversight and concern about recycling.

And, hey, that’s great. But I think I think on on the Rose-Marie side, I’m super worried about what this material is and what its lifetime is. And yeah. Do we wait 20 years to find out if it’s going to work or not?

Because if it works five years and they start to come apart, that’s problem.

Well, and this is interesting on on LinkedIn, a post from RWC, RW renewables, they’re in, they sort have their own info graphic about this, the cycle which they’ve they’ve tested recyclable wind turbine blade and there’s therefore steps as one decommission to and milder acidic solution.

Three, reclaim separate components for reuse. But my question to you both is in Sep two, why the word mild? So Amercian mild a, I would think that because winter and blaze are super tough, that it would have to be incredibly not mild and zoomer strong acidic acid.

But why do they specifically use the word mild? There is a marketing because it seems like if the Zahawi of this gentle solution, that doesn’t seem like it would cut it to me.

I just think acid sounds like a harsh, harsh word that you don’t want in your ad copy.

That’s that’s so nice and green and friendly. Yeah, that makes sense. Yeah. Is that your take?

Yeah. No, what Vestas was talking about actually had a Vestas recycling key person in that or a catapult discussion. They actually showed a beaker full of this acidic solution and they named what it was. And at the time I thought, oh, that’s mildly acidic.

It’s not. So if uric acid, which is what I assumed it was going to be, but there was some mild it was like some mild acid that they were putting it in. Now, there may be more to the chemistry, like the thermostat, maybe reacting to what the particular acid is.

And so it’s like a key unlocking a door. It’s going to break apart.

Yeah. The crosslinking itself doesn’t have to be a battering ram.

Got it right. It may not have to be that way. Right. So but the way the vest is described, the technology was it was still in beaker form. What I mean, beaker form. It’s still being it’s still being developed in the lab and that they didn’t have a manufacture flushed out on what this material was.

Investors, I asked the Vestas person and the overall community, hey, hey, look on recycling, which one’s going to get their first thermal setts? Recyclable thermostats are recyclable thermal plastics. And the the impression I got was thermal plastics are going to be there sooner, that there’s already existing technology in thermal plastics.

And because of the advantages manufacturing wise and thermoplastic, that may be the winner. There may be a thermal set out there that’s doing this thing. But we need to really look at thermal plastics.

It sounds like it’s this announcement by Siemens. Gamesa strikes you as just a little head or just a little odd or a little bit just incomplete or just we don’t have enough information to really know what they’re up to.

We don’t know right yet. And I think as the marketplace develops, if you see developers and particularly in Europe developers in Europe choosing Siemens, Gamesa because of the recyclability of the blades, then you’ll know like this is going to be a game changer.

If what I think is going to happen, the the accountants and the insurance people are going to step in and say, hey, and the D and are the world are going to step in and say, show it. We really want to make sure this is going to work.

We love the concept. We love the idea. It’s great. But you I can’t take the risk. So you’re going to have to prove it to me. I think that phase needs to be fleshed out a little bit more.

Well, what is the risk specifically? I mean, you know, like Veolia is shredding up blades again. If you buy a blade today and install wind turbines today, you got 20 years to figure out what to do with it from recyclability stand.

Right. Like, do you need a solution that’s like ready to go now or are you kind of OK, a thing like, OK, we got 20 years. That’s a long time. We have iPhones 20 years ago. I mean, think of how much the world has changed.

I mean, we have like Tyrannosaurus Rex in 20 years, just run around, just eat all the old blades. And that’s that’s what they do. We have no idea what’s going to happen. I mean, but in all seriousness, like is it something that they need to worry about?

Like they would make a buying decision based on that today, knowing how much time they have for other companies to make more solutions?

Yeah, I think that the OEMs are really worried that there’s going to be regulations soon about and you’re already starting to see that. But I know that they’ve been thinking about this for for a long time, probably at least ten years before, you know, as soon as anybody started to notice that wind turbine blades weren’t recyclable.

Well, OK, at some point, someone’s going to make a regulation that you can’t sell a blade that’s not recyclable. And that’s why everybody is I mean, we get lots of announcements now, but it’s been consistent progress over a lot of a lot of years already.

So I think that that’s the the real driver for it. But yeah, I did take your point earlier. I laughed at you, Dan, about you just waiting, Teddy. That is to say, if you could recycle it. But I guess I mean, it could it until you get to that point, you don’t know.

Did the blade last that long? It’s a bit hard to test things like, you know, how durable is something in real weather conditions. And yeah, we take their word for it that because they were able to recycle, you know, a little piece in the lab, that that’s the same as being able to recycle a full blade at

the end of its lifetime. So maybe. Maybe this is a premature announcement to try and get some some advantage, I guess there’s no easy way to tell.

Well, I think that is a good thing. Like obviously all these, especially with offshore, I mean, it’s going to be complicated to decommission offshore wind farms. Have there been many decommissioned offshore wind farms to this point? That seems like just a obviously a really expensive process, number one.

And number two, that that whole thing might change tremendously with technology. I mean, they have some super ship where they can just process it right there on the boat and you might not even want to recycle it the way it was intended.

Once you have some new solution 20 years from now where it’s like, yeah, we could do what they intended 20 years ago, but now that we have this gigantic, you know, ship that’s got a grinder on it, it’s just going to make way more sense to do it that way.

Like we you know, we have no idea what could be out there. All right. Well, that’s going to do it for this week’s episode of the uptime podcast. Thanks so much for listening. Be sure to subscribe on Spotify, iTunes, Stitcher, YouTube, wherever you listen or watch again.

Be sure to check out uptime tech news and subscribe. You’ll find the links in that in the description below. And subscribe to our Rosemary Barnes’s YouTube channel. Engineering with Rosie will you’ll get more videos, tutorials, all that sort of stuff on everything, renewable energy.

We will see here next week on the Uptime Wind Energy Podcast. Operating a profitable wind farm is all about mitigating costs, minimizing risks and being efficient with maintenance, repairs and upgrades. It’s incredibly expensive to send a team of rope access technicians up tower to make even simple repairs.

We also know how costly lightning damage can be requiring inspection, repairs and downtime for even minor lightning strikes. Maximize the time efficiency of your techs and prevent future lightning damage by installing our strike tape loops upgrade the next time your crews are going up on ropes.

Learn more in today’s show notes or visit us on the Web. WeatherGuardwind.com.