According to industry experts, between 1-3% of lightning strikes to wind turbine blades result in wind turbine blade lightning damage. In some of those cases, damage is severe (and very expensive). Why? An article in PES Wind by Weather Guard Lightning Tech President and CEO Allen Hall explains how the variables of different types of lightning, the location, turbine type, and other factors combine to produce different types and varying degrees of damage.

“The desires of lightning are fairly basic. If a strike does not connect properly to the wind turbine blade lightning protection system (LPS), due to the wrong lightning attachment, it will puncture the blade to reach the down conductor, carbon spar cap, or both.

That means the damage hidden inside the blade can be considerably larger than a small hole on the exterior shell. …” Read the full article in PES Magazine here.

Variables contributing to lightning damage of wind turbine blades – and costs of repairs

When a lightning strike occurs, as described in the article, many variables, including location, lightning strike type, and the size and structure of the turbine, combine to dole out the damage. But owners and operators are (rightly) far more concerned with steps to take after a strike has potentially damaged a blade.

A common question from operators in lightning prone regions is, ‘If a turbine takes a lightning strike, should it be shut down until technicians can inspect it?’…[and] ‘What should happen once blade damage is discovered?’

PES Wind Power and Energy Solutions Issue 2, 2023

There are different approaches and many ‘acceptable’ answers to both of those questions. While proper investigations and assessments are critical, sometimes it’s ok to let an older turbine just run until there are safety issues.

Wind turbine blade lighting protection and damage assessment

It’s important to remember that the majority of turbines that are out of warranty still need to operate another decade or more. In those cases, an operator needs to know the category of damage in order to determine the best response.

The independent blade consultants at Wind Power LAB have created a simple series of steps to evaluate and put damaged blades back in service.

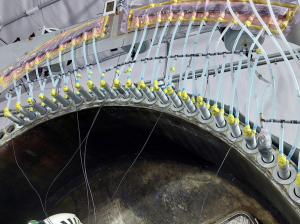

The first step is to photograph and inspect the external surfaces of the wind turbine blade. The second step is internal blade inspections, as most structural wind turbine blade lightning damage occurs on the inside of a blade, where bond lines and composite shear web or box beam structures carry massive blade loads. Internal inspections are critical to preventing catastrophic failures due to internal lightning damage.

While internal inspections can be complicated, blade inspection instruments and methodologies, available from numerous companies, can accurately assess and measure damages, including the resistance of the lightning protection system (LPS). Some of those options are detailed in the PES Wind article.

The third step to assessing wind turbine lightning damage is to measure the resistance of the lightning protection system (LPS). A simple check can identify issues such as broken or degraded down conductors that can cause internal structural damage to blades.

Wind turbine blade lightning damage: Approaches to repairs

Large operators often have a historic damage database which, combined with knowledge of a particular blade style, can help guide repair decisions. Operators with less data and context may struggle with next steps.

An investigation by a blade-specific engineer can be useful, especially when glades have experienced multiple strikes.

And just as important as determining how to repair – or if repair is truly the best response – is taking steps to prevent additional lightning damage of wind turbine blades. Again, inspection is the first step – to understand which factors are primarily contributing to the multiple strikes, and how well the wind turbine blade lightning protection system is functioning.

In addition to blade repairs, certain retrofits and refurbishment may be viable to balance maintenance and production costs to increase the ROI of both the blades and the turbines. Click here to read the full article (no subscription required).

This abbreviated article is a shallow dive into the subject of wind turbine blade lightning damage. Please see PES Wind for a more in-depth review of the subject. You may also be interested in Lightning Damage Isn’t Always Force Majeuere in the previous issue.

Additional reading:

Are Winglets worth the Retrofit Costs?

Turbine Blade Maintenance: More than a safety issue

Leading Edge Erosion: A Big Problem for Operators

UPTIME Podcast: Turbine Blade Aerodynamics and how vortex generators work