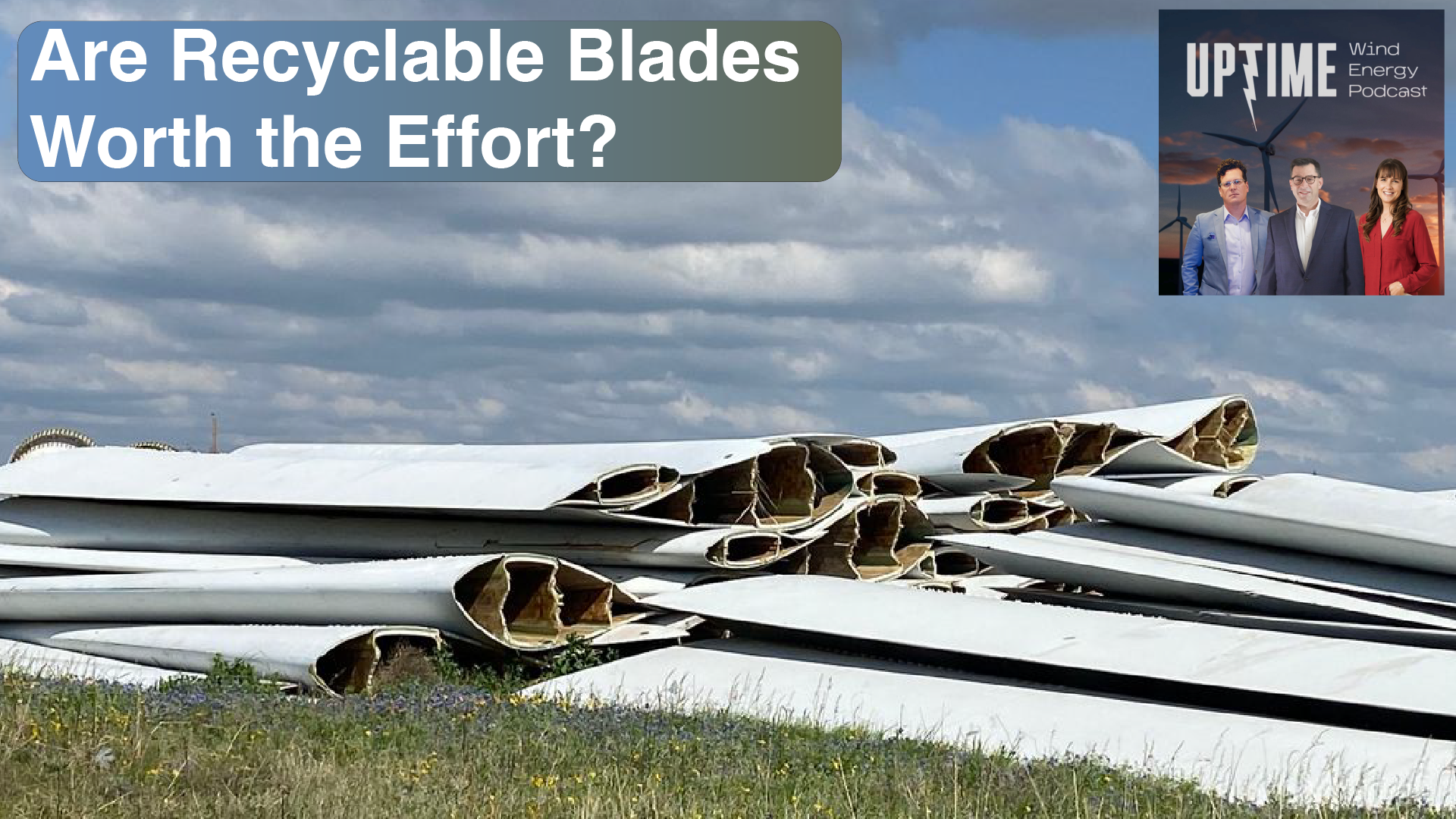

Continuum is planning to build six wind turbine blade recycling centers across Europe. In the US, several companies are competing to recycle blades into construction materials. With recycling a viable option for blades made of standard epoxy resins, are new recyclable resins worth the effort? Joel, Rosemary and Allen discuss the options for blade recycling and the low-carbon options for future blades.

Visit Pardalote Consulting at https://www.pardaloteconsulting.com

Wind Power Lab – https://windpowerlab.com

Weather Guard Lightning Tech – www.weatherguardwind.com

Intelstor – https://www.intelstor.com

Podcast: Play in new window | Download

Sign up now for Uptime Tech News, our weekly email update on all things wind technology. This episode is sponsored by Weather Guard Lightning Tech. Learn more about Weather Guard’s StrikeTape Wind Turbine LPS retrofit. Follow the show on Facebook, YouTube, Twitter, Linkedin and visit Weather Guard on the web. And subscribe to Rosemary Barnes’ YouTube channel here. Have a question we can answer on the show? Email us!

Bonus 149

Allen Hall: All right, so this is the bonus episode of the Uptime podcast. Lucky you. Because Rosemary is talking about blade recycling, and there’s a lot of new blade recycling initiatives around the world, and particularly in Europe where six blade recycling factors would be built between now and 2030 Now, there’s a a lot of questions about what the right approach is, which is the lowest carbon dioxide method to, to recycle blades. Should we bury them? Should we not bury them? Should we turn ’em into furniture? This is a really good bonus episode.

Allen Hall: Well worth listening cause there’s a, a lot of good viewpoints about this. I’m Allen Hall, president of Weather Guard Lightning Tech, and I’m here with my good friend from Wind Power Lab, Joel Saxon, and the soon to be guest host of The Fully Charged Live Event in Australia, Rosemary Barnes. And this is the Uptime Wind Energy Podcast.

Allen Hall: Well, Rosemary, Denmark base continuum is planning to build six large scale wind turbine blade recycling facilities all across Europe. The first factory is scheduled to be built in southwest Denmark. Of course, why we’re built anywhere else and. It’s gonna be an operation at the end of 2024, end of next year.

Allen Hall: The second factory is planned for the uk. It’s gonna be all six factories they think are be done by 2030. Right. So they’re actually gonna meet a 2030 goal. Each factory can process a minimum of 36,000 tons of blades a year. That’s a lot of blades. And they’re gonna turn this into construction material.

Allen Hall: It doesn’t sound like they’re gonna burn it. It sounds like they’re gonna chop it up and add it to concrete or other. Construction related materials to reinforce them, make ’em better. You got fiber in there, right? So that makes sense. You could chop it up and reinforce different things. Question is with GE slash LM working on recyclable blade resins.

Allen Hall: Same thing for Siemens Mesa. They’ve got this super break DOWNABLE resin for these recycle blade projects. Does this all make sense if you’re, if I’m gonna build a factory to recycle blades and they’re gonna make blades recyclable in a different way, coming up like now there seems like there’s a mix of technology and factories going in the wrong direction.

Allen Hall: Which one is the right path?

Rosemary Barnes: Well, I think the eventual right path is to have blades that are really easily recyclable, but in the meantime, the, you know, we haven’t got recyclable blades yet, and when we do, it’ll be another 20 to 30, or we need to recycle the bulk of those blades. So, yes. Yeah. In the meantime, we need a way to recycle all the blades that already exist, and so this would.

Rosemary Barnes: be that method. But I haven’t seen too many details of it cuz already, I mean, there’s already ways to recycle blades depending on what your definition of recycling is. I pretty sure in Germany it’s already illegal to send them to landfill and so they’re processing them on the smelt cement kiln. So that’s one way of doing it.

Rosemary Barnes: You. Also, yeah, I mean there’s a, the range of things you can do, you can shred them and put them into the kind of like low structural requirements applications. Like they put them in decking material or they can make ’em into, I don’t know, composite panels for truck beds or dashboards, stuff like that, that doesn’t really have too much structural requirements.

Rosemary Barnes: So it’s okay to, yeah, just kind of like shred, shred the fibers. This process. I’m assuming is different to those, but I haven’t actually seen enough detail to say for sure. But I think it’s, it is really interesting with Blade recycling. People really hate to put them into landfill, but in terms of CO2 emissions, that’s probably.

Rosemary Barnes: The best thing you can do with them just about, because while they’re in landfill, they’re, you know, all the carbon that’s in them is, is, is staying underground. If you burn it, for example, then instead of landfill, then you are using air fill, you know, , the CO2 is going into the atmosphere, which isn’t, isn’t helpful.

Rosemary Barnes: So you kind of, people tend to conflate the two issues of. Of plastics and plastic waste. With climate change, kind of assuming that what’s one good for one is good for the other, and in so many cases it’s kind of actually attention. They’re in opposition. I did see with this this method, this new new method that Continuum has.

Rosemary Barnes: They’re saying that it’s CO2 neutral. haven’t seen the details, so I don’t know how they arrive at that. And, you know, it is, sometimes people call things CO2 neutral, but it’s really because they, you know, pay a farmer own Zimbabwe and not cut down a tree or something stupid like that. So I would like to see more details.

Rosemary Barnes: But that’s at. You know better than, than the. I was just listening to a, a Bloomberg n e f podcast yesterday. It was called Switched On. It’s pretty, pretty good one. Not as good as ours, obviously, but you know, second option if people wanna find another , another podcast to listen to. And this episode was on petrochemicals and trying to reduce emissions from that industry.

Rosemary Barnes: And one of the experts that they had on did mention that yeah, if. Burn. One of the, the biggest problems with decarbonizing, petrochemicals is the end of life stuff. And. Yeah, obviously if you, if you burn plastics then you’re gonna release that CO2 into the atmosphere. But he also mentioned that there’s some recycling methods.

Rosemary Barnes: I mean, all recycling methods have some CO2 emissions and some kinds of chemical recycling actually have higher emissions associated with them than if you just burnt the, the plastics. So get out. Really. Yeah. Yeah. So it sounds, it sounds super green. It sounds like, you know, no-brainer. Of course, we should be recycling all our plastics, but if you are primarily concerned about climate change, then it’s, it’s definitely Not that straightforward.

Rosemary Barnes: And I personally think like if you’ve got, if you’re not land constrained, you know, like the US and Australia, we actually don’t have too much problem with running outta space for landfill. It’s not a bad place. To store, store the blades, you know, while we come up with better recycling methods, I’d rather see blades in landfill than you know, the, all the carbon in them emitted into the atmosphere, that’s for sure.

Rosemary Barnes: Europe’s a sort of a different question because they do struggle to find space for landfill and yeah, so they, they have other reasons for not wanting to do that, but it is one of. Topics where, yeah, it sounds really obvious that if you, you know, love the environment, then of course you should want to recycle everything.

Rosemary Barnes: It’s not always better for the, for climate change though. Upcycling,

Joel Saxum: that’s my favorite, right? When someone’s taking these turbines and turning ’em into chairs and desks and, and park benches and stuff, I think it’s super cool. Oh yeah. But you know what my problem with it is, is I talked to someone the other day.

Joel Saxum: Check this desk out. And I was like, man, that desk is sweet. It had like the trailing edge slid out and was for your keyboard. And it was, and I was like, well, how much for it? It’s it 3,500 bucks? It’s like, man, who’s paying

Rosemary Barnes: that for a desk? Yeah. , like, I hope they I hope they covered up the carbon fiber world.

Rosemary Barnes: Yeah. So itchy. It’s not like a surface. I would wanna be laying my hands all over every day. Right. They did a

Joel Saxum: fantastic job on it. Like the, the, the desk itself was, they had even like refinished the gel coat, so it was like a matte finish almost on it. And they covered the ends and like sanded it. Well, and the, it was, it was done really well and like the legs were made outta parts of the sheer webs and stuff like that, but like, you know, smoothed out and whatnot.

Joel Saxum: Oh. And it, and it had the power thing in it. Br you can go up and down with it.

Rosemary Barnes: Oh, that’s a master. Yeah. Yeah. Oh yeah. Sit stand is a master. Especially if you . If you’ve got a baby who wants to nap on you all the time, yeah. Then that’s the way you can get some stuff done with a baby in the carrier and standing up at, at the sit stand desk.

Rosemary Barnes: Highly recommend. I did actually talk to some architectural firm a little while ago, and actually it’s just reminded me that we never went anywhere. I should follow up, but they wanted to make like facades. Mm-hmm. and, you know, like architectural features. Bits of wind turbine blades and they look, they look so cool if you cut them in cross section so you can see the layers of glass, right.

Rosemary Barnes: It looks really nice. They were going to, you know, like make some nice paneling out of it, but it, it is kind of. Gimmicky. It’s not an environmental solution. It’s more just like, it’s, it’s a cool product. They look cool. It makes you, you know, reminds you that, you know, it’s something to do with clean energy and that that gives you warm, fuzzy feelings.

Rosemary Barnes: But it’s not a recycling solution. Like I, I get kind of irritated when you, you see in your social media feed, oh, here’s a bike shelter made from a wind turbine blade. See, you can do something with it. How many bike shelters do we actually need? Or like playground equipment or what like is every single pedestrian bridge and I don’t know, picnic table, it’s just all going to be wind turbine blades are across the whole world.

Rosemary Barnes: So, you know, get rid of get rid of a meaningful amount of this stuff. Yeah, I, I don’t know. I don’t see it as a scalable solution. , and I mean, they are, they are pretty much totally inert. A lot of you know, like. Clean energy types, try and say that they’re toxic. It’s, it’s totally rubbish. You know, like they’re, they’re inert.

Rosemary Barnes: They’re gonna look exactly the same. If you dig ’em up in 50 years, they’re gonna look the same as they they do now. And yeah, that does sound like to me, it’s not, not a problem. Like, instead of thinking of it as landfill, just think of it as, you know, long term storage. You put them, put them there, and wait until we have the technology to.

Rosemary Barnes: Properly recycle them in a way that’s actually, you know, got good environmental outcome. Well, I’ll give you another story

Joel Saxum: from the state of the, the great state of Wyoming. So if you’ve ever driven out there, so if you’ve driven in Wyoming, South Dakota, North Dakota, man, Utah, co parts of Colorado, you’ll see snow fence, right?

Joel Saxum: So snow fence is Desi, it’s, it’s on the edge of the right of way so that when that wicked wind blows, it doesn’t create drifts across the highway. Why not use wind turbine blades for snow? Then you can use hundreds of miles

Allen Hall: of them. I’m filling out the L l C paperwork right now, Joel.

Joel Saxum: We should be in business by tonight.

Joel Saxum: So I’ll go back to the beginning of this conversation for Rosemary. So here’s the thought I was having while you were kind of running through your first the chatting about the six factories over in Europe and, and those things. So as the Reliable Blade, the Zebra Project, all these things are put in these, these, the resin or the, the, the resins that are optimized for recycling together right now.

Joel Saxum: So what it was r w e that installed the, the recycled blades already. Was it just this, this fall? So that was on that, the ca cas casket Sea or something like that in Germany. So now they’ve installed those now, so their lifespan is 20 years, 25 years. So even if they’re building these six factories that can break these turbines down as we, as we have them today.

Joel Saxum: If a turbine was installed today and it wasn’t a, a recyclable blade, you have 20, 25 years of the possibility of these factories operating. How does someone justify the CapEx to build these factories? Understanding that in probably 25 to 30 years, they’re gonna be either have to be repurposed for something else, or they’re just gonna be shut down because everything else is going to have this new recyclable resin technology in it.

Joel Saxum: So how, how does a

Rosemary Barnes: company, I think that sounds like a good, a good duration for a factory, doesn’t it? I mean wind turbine blade factories that were built 25 years ago were. They’re not still operating close to, you know, they would’ve been in that case built to do what, like 10, 15, maybe 20 meter blades.

Rosemary Barnes: So if they do still exist, then they’ve had to build whole new facilities on top of them to deal with today’s blades. I to me that doesn’t sound that that wrong of. Yeah, project duration and bearing in mind that it’s not like, okay, so the first, the very first turbine with the very first three recyclable blades has been installed, it doesn’t mean that from next year a hundred percent of blades are gonna be made that way.

Rosemary Barnes: It’s gonna be a changeover and Yeah. And until people start mandating that you have to that you have to do it this way. I don’t think it’s gonna take the, the bulk of the. . And I, I would expect that’s still five years away. I, I don’t know, but that would’ve been my guess. Okay.

Joel Saxum: So if we, if we do an average of 36,000, divided by five tons.

Joel Saxum: That’s 7,200 blades per factory per year. Divide that by three. That’s 2,400 turbines or the blades per factory per year. That’s only, that’s 14,000 turbines per year for those six factories to be able to process. If they’re running at a hundred percent capacity, which they won’t industry capacity today, those six factories handle every blade that comes out or that gets pulled off of a.

Rosemary Barnes: That’s the answer to Joel’s question about why, you know, snow fences or, you know, any other random thing you can think of. Why aren’t these made out of wind turbine blades? It’s because the cost of getting wind turbine blades to, you know, wherever is more than the cost of buying a new, new product from a, you know, established supply chain.

Rosemary Barnes: It’s whenever I work on these kind of projects that wanna recycle wind turbine bayes or repurpose them into other, , that’s always the biggest problem that, you know, you’ve got, you’re decommissioning wind farms at all sorts of random locations, so you have to temporarily go set up some processing plant on site, or you have to transport ridiculous coal blades, which is, you know, just like ridiculously expensive for an a nearly valueless.

Rosemary Barnes: Material you know, it’s worth it. The cost to get the blades there is worth it because you’re building a very valuable wind turbine. But at the end of the life, you know, you’ve got some building product or whatever, that’s not quite the way you would ideally like it to be. You know, they’re curved and then if you slice a blade into pieces, the curve at the root is very different to the curve at the tip.

Rosemary Barnes: And so that’s why you need like an architectural firm with their, you know, 3d yeah, their, their. Designed to be able to slice it up and reassemble it into cool architectural shapes. That’s, that’s what you need. Otherwise, your snow fence is gonna be, you know, totally, totally wonky and full of holes and you know, not, not really doing anything.

Rosemary Barnes: Not to mention the extra emissions from trucking. These things, you know, all the way across the country or shipping them across the world, like that’s definitely not a good environmental outcome. It just gives people a warm fuzzy from from thinking that we’re not wasting something.

Joel Saxum: Yeah. It’s like we were talked about a couple of weeks ago about ocean cleanup stuff.

Joel Saxum: When you brought up the points of the emissions from the vessels going out there to the, to the plastic patch, what is the reality of it?

Allen Hall: China’s making blades out or whatever, and I don’t see them making recyclable blades. Central America, south America is probably gonna make him out of epoxy.

Allen Hall: Cause it makes sense. It make, it just makes sense. The supply chains there, they’re gonna do it. I think you’re taking a risk making out of recyclable resin because no one has any experience with it. Yeah. In large scale structural applications, if you have a recyclable method at the end that has proven itself to, to work, then I think you as a, as an O E M.

Allen Hall: I start thinking, I’m not gonna pay for this super expensive recyclable resin. When I have a recycling method that I trust and has been validated as being CO2 neutral. I, I go, we’re out. We’re out of the recyclable resin system. I think the, I think that’s inevitable, right? What am I missing here? Rosemary?

Joel Saxum: You’re missing ESG goals.

Rosemary Barnes: Oh, but you have to care about landfill. Like for, for climate. For net zero, I sure it’s not, I care about the I, I, I don’t care about landfill. I care so much less about landfill than I care about airfield. You, you know, like, I just don’t wanna put carbon dioxide in the atmosphere.

Rosemary Barnes: Landfill, if it’s well managed is not, you know, like it’s not. , you cut up these wind turbine blades and then micro and, and properly put them into a well-managed landfill. Microplastics aren’t making it into you know, sensitive ecosystems from that. They’re just, they’re inertly doing whatever. I think we have a thousand bigger problems to put our smart brains onto at the moment than worrying about, you know fully circular economy for.

Rosemary Barnes: every aspect of energy technologies personally. So did I

Allen Hall: D Joel. Now I’m Joel. I’ll let you be the arbiter here. Did I just convince Rosemary that it’s okay to stick with old resin systems and to shred up blades? I think I just did that. I heard it. Did that just happen? You

Joel Saxum: heard it here, January 9th, 19th, 2023 5:40 PM

Allen Hall: Central time.

Allen Hall: No, I didn’t. I Hey, I’m, I’m off our recycling. I, I’m pushing the ocean cleanup in. No, Rosemary hates me. No, she didn’t hate me for it, but she disapproved. She’s, she, she sends me disapproval messages via Slack all the time about it. , but. , but, but I am for recycling. But I think there’s a, a thing that makes sense, right?

Allen Hall: It’s a pragmatic, there’s a pragmatic future economy. Yeah. You

Rosemary Barnes: have to know what you’re trying to achieve. Right? I think that’s gonna, it’s what problem am I trying to solve? And recycling doesn’t, it’s not a climate solution. It’s a, a plastic waste solution. And you, you, you have to have a problem with it.

Rosemary Barnes: Going into landfill for some other non climate reason to, to bother is Yeah, my. .

Joel Saxum: I’d say Brno. There you go. Put ’em in. Put ’em in. If you’re, if you’re a rancher that has wind farms and they’re decommissioning them, line those things up three wide. And take a D 10 over the top of them, crush ’em up, and then put a cap of class five on it.

Joel Saxum: And now you’ve got a nice road with a stable bed that won’t sink into the mud in the spring.

Allen Hall: Joel, I, you know, you bring up this, I wasn’t gonna say it, but now you, you made me say it. I had meant to be sitting on an airplane for a couple of hours next to a guy. I got upgraded first class. It’s probably one of the few times this has ever happened in my life.

Allen Hall: So it’s lightning tech. So I’m sitting next to a guy who Well, yeah. We’re moving up with the world. So I’m sitting next to a guy who does roads. I they, they do, they do improvement for roads and they were adding glass to asphalt to make the roads not have potholes anymore. And he said, you wouldn’t believe how great these roads are.

Allen Hall: They never had potholes. Kids are out, skateboarding riding and their bikes. There’s no holes in the road they get, oh, that’d be great cause it’s expensive. . Okay, I just gave you a huge supply of chop fiber. Make your asphalt roads and get rid of my potholes. Yeah. Two problems.

Joel Saxum: So I mean, it’s, but that’s how, that’s how you’ve been making strong concrete for years, right?

Joel Saxum: For hundred years. Years, yeah. Is, is putting fiber in it. I mean, and it comes in 50 pound bags. Just dump it in and mix it up. It’s the same thing. Dump it in.

Rosemary Barnes: But you get that. That we go carbon fiber fiberglass, I mean from other industries too. I think wind turbine blades is something like 5% of global composite volumes.

Rosemary Barnes: So it’s, it’s really interesting to me that wind turbine blades are the only industry where you, you care about what happens to that at the end of the life and not the 95% of the rest of it.

Joel Saxum: It’s because clean energy’s a political issue that’s why. We know this.