Having worked with Aerones in the past, we’ve seen the benefit of the company’s robotic inspections and repairs firsthand. This article includes highlights from the first installment of the company’s Wind Academy Series, which explained how the company’s inspection and repair services can improve lightning protection systems, with the goal of extending blade life and increasing the turbine’s productivity.

Aerones: Robotics Lead to Better Lightning Protection

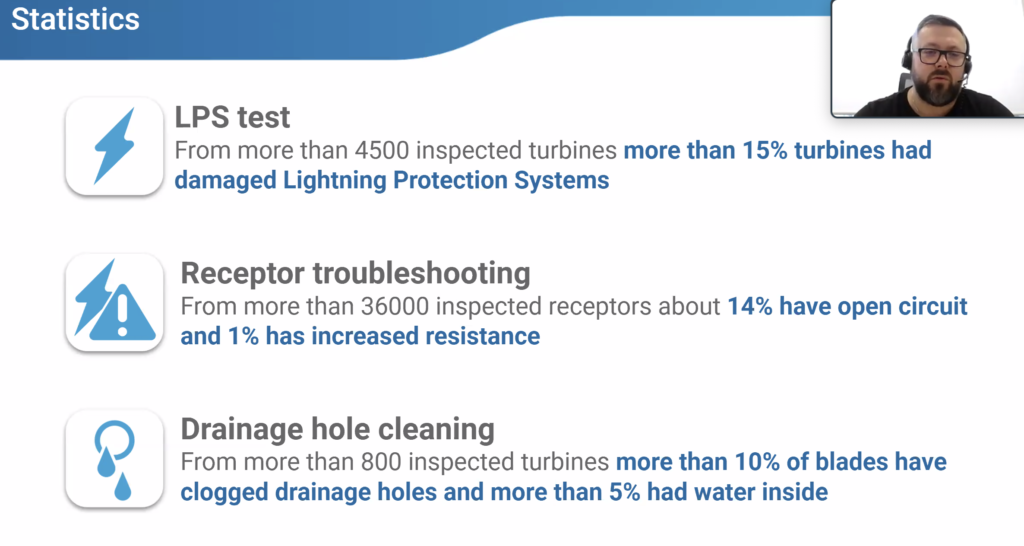

“Approximately 15% of the LPS that Aerones robotics test are faulty.” ~ Kaspars Litavnieks, Business Development

During a recent webinar, Kaspars Litavnieks, Aerones Business Development Team Leader, focused on what robots are doing – and what they’ll soon be able to do – to help operators extend the life of their turbines.

Robots, generally, work faster than technicians and can operate in some conditions that technicians can’t, Litavnieks said. On average robots can work 5 days a week, given typical (not ideal) weather conditions.

While drones are used primarily for inspections, robots are able to do more. Many wind farm operators now rely on robots to inspect and troubleshoot blades and gear boxes, to clean blade surfaces, and to fix oxidated wires, among other things.

What kind of work do robots do on wind turbines?

According to insurance industry data, Litavnieks said, blades are the most frequently damaged.

Blade Cleaning and Maintenance

Blade cleaning is probably the best understood of the services robots provide, but why is a clean blade so important? The cleaner the blade surface, the more aerodynamic (and therefore, more productive) the turbine. Dust and debris also affect aerodynamics, and more, they increase the risk of failures due to lightning.

Clogged drain holes are “a natural lightning attraction,” Litavnieks said.

When water collects inside a blade, it increases lightning attraction and because the water is conductive. Extra water also may also affect power production.

Robotic Inspections, Replacing Receptors, and other Repairs

On average it takes about 90 minutes to do a LPS inspection of a blade, Litavnieks said, although if a hoist is needed to get the robot onto the turbine, it may take longer.

What if there are faulty down conductors? Or a poor connection to the down conductor?

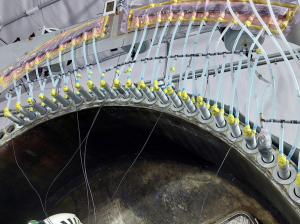

With a special receiver fixed on the robotic platform, the Aerones robot system can scan a blade to diagnose broken down conductors. If the down conductor is faulty due to oxidation, the robot can perform a high voltage welding operation to fix the connection.

If the repair is unsuccessful or the scan indicates another reason for the poor connection, a ropes technician may need to open up the blade to do the repair – but the technician will be armed with all the necessary information, thanks to the robotic inspection.

Aerones is currently testing using robots to replace damaged receptors in the field, during a regular inspection, when a faulty receptor is found. Initial field tests have shown promising results.

Litavnieks said that while robots have been able to successfully change receptors on new turbines, there are limits, mostly due to weathering and wear. After a year or two of service, bolts can get rusty, and other degradation can hinder receptor change, he said.

“Prevention is Better than Cure”

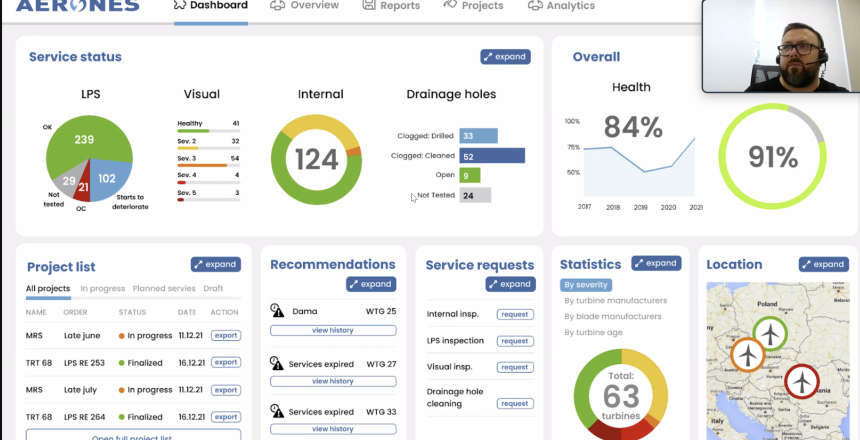

Litavnieks shared some of the company’s statistics that make a good argument for regular turbine maintenance.

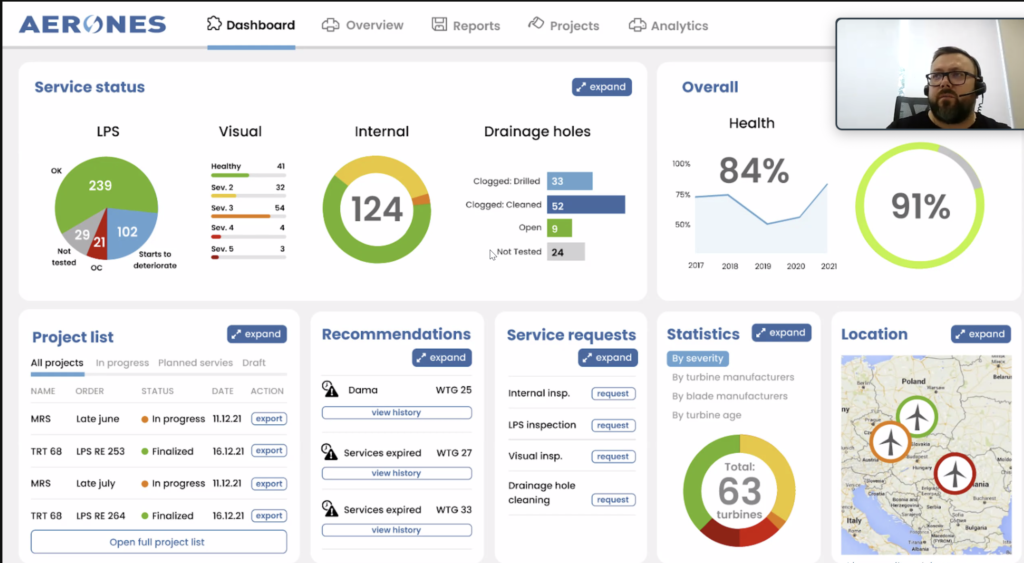

After an Aerones service, he explained, customers receive a wealth of data in a dashboard-formatted report, which the company hopes they will use to complete necessary preventative maintenance.

Turbine Blade Maintenance: More than a Safety Issue

The webinar featured some great videos of Aerones technicians (and robots) in the field.

The company plans additional webinars, including one focused on Leading Edge repairs, which is scheduled for June 21, 2022. Learn more at the Aerones website.

Worth a listen: Aerones Co-Founder and Managing Director Dainis Kruze on How Robots Help Optimize Wind Turbine Maintenance & Repairs

Keep up with the latest from the Uptime Wind Energy Podcast! Subscribe to get it in your in-box every week.