How can we prevent wind turbine blade icing? What we know now

Ice can stop wind turbines cold, as much of the world learned when a major winter storm hit Texas last year. But wind is a proven energy source, producing power even in very cold climates for decades. So, while the Texas ice storm of 2021 was seen as a setback by some outside the wind industry, in fact, plenty of pre-existing technologies could have been used to reduce or avoid the wind turbine ice damage in Texas.

One of the world’s leading researchers on the effects of icing on wind turbines, Dr. Hui Hu, is the Director of the Advanced Flow Diagnostics and Experimental Aerodynamics Laboratory at Iowa State University. Dr. Hu discussed some existing wind turbine deicing technologies, and new ones in development, in a recent Uptime podcast. You can listen to the full interview here.

The short story: he’s very optimistic about more affordable and effective systems for wind turbine deicing in the near future. The longer story involves the science of ice, water droplets, wind, and blade aerodynamics. Read on for some of that – in layman’s terms – along with notes on how ice may increase lightning risks to wind turbines.

Grab the Guide to Wind Turbine Blade Anti-Icing Technologies here

Wind Turbine Ice Damage is Not a New Problem

Understandably, last fall’s Winterwind21 (SE) conference reviewed the Texas turbine freeze event in detail, and a variety of potential remedies and prevention techniques were discussed. Keynote speaker Rosemary Barnes of Pardalote, a consulting service for energy transition technologies (and a regular co-host of the Uptime podcast ) noted that balancing production costs and reliability is the greatest challenge to the future of renewables.

As Barnes explained, since extreme weather events like the Texas Freeze highlight weaknesses in the electrical grids, and because such storms are expected to become more common due to climate change, “all eyes are on blade heating and winterized wind turbines now, making this an unprecedented opportunity for the winter wind community.”

“Those of us working in the field know that there are technologies that – if installed – could have allowed Texas’ wind turbines to operate through the cold snap. But… if every turbine in every site with a climate like Texas is winterized in the future, the main thing we will achieve will be to make wind energy very expensive,” Barnes said at the conference.

“Future clean energy systems need to be low cost as well as reliable.” – Rosemary Barnes at Winterwind21

With that perspective, let’s look at some of the existing systems, recent research, and consider hybrid models (and additional challenges) on the horizon.

Anti-Icing Systems for Wind Turbine Blades

Wind turbines can be weatherized to operate during ice storms or freezing temperature – or can respond to weather risks and shut themselves down to avoid damage.

Anti-icing coatings are widely used in cold climates. Brian Huskinson, CEO of Elemental Coatings, explains the technology and its application here.

Heating and fabric protection layers are designed to be thin (~.5mm), so as to not interfere with blade aerodynamics. WICETEC’s Business Development Manager, Lasse Hietikko, explains how these turbine blade heating systems work in cold climates worldwide.

It’s important to understand that all climates pose different hazards, even where temperatures and wind speeds are similar. A cold dry climate varies significantly from an offshore wind farm in a cold ocean. Even in the same general location, risks are very site-specific, as DNVGL engineer Alex Byrne explained in a 2020 interview. And, weather patterns change. A recent article in The Guardian highlighted the alarming rising in lightning activity in the high arctic – more than a nine-fold increase in just one year – making understanding the interaction between lightning protection systems (LPS) and deicing technologies an even higher priority. (See LPS and deicing section below.)

What We’ve Learned from Aerospace De-icing

“Airplanes are pampered machines.” — Weather Guard CEO Allen Hall

Obviously, deicing a plane on a tarmac is far easier than de-icing a wind turbine – especially in a storm. And airplanes are routinely on the ground, making “routine” maintenance procedures much easier.

So, while there are plenty of (important and) practical differences between airplane wings and turbine blades, many of the same technologies used in aerospace absolutely apply when addressing wind turbine icing problems.

More about protection of aircraft here.

For example, spraying de-icing solution from a helicopter onto ice-prone surfaces can provide a temporary solution for deicing wind turbines – assuming, of course, that it’s safe to fly a helicopter in an ice storm.

A number of hydrophobic coatings and heating systems were developed by or in conjunction with aerospace researchers.

Different Types of Ice Require Different Approaches to Protect Wind Turbine Blades

All ice is not the same.

In colder and drier climates, like Iowa, most of the ice is rime ice, which looks like ice crystals. In humid conditions, more water in the air creates glaze icing.

Iowa’s typically cold but dry winter conditions lend themselves to the development of rime icing, whereas more water in the air causes glaze icing, Hu explained.

Glaze icing is what coated Wind Turbine Blades in TX storm. Glaze ice is dense, making it smooth. And, it’s often thick. Think of an extra coating of “glass” you might find on your windshield after rain has turned to sleet, and temperatures drop. That’s glaze ice.

Glaze icing more seriously affects the aerodynamics of turbine blades.

When the less dense rime ice forms on wind turbines in Iowa, they may lose 5% to 10% of their power production capability. In contrast, the much denser (heavier) glaze ice, such as what coated wind turbine blades in the Texas storm, caused them to lose around 80% or more of their power production.

This is a simplified description, of course. Rime ice can be soft (less dense than hard rime) and clear ice, which is similar in appearance to glaze ice, is formed through a completely different process, which can occur during freezing rain or in drizzle conditions. While clear ice and glaze ice typically cause more problems than rime, all of these types of ice can form on the surface of an aircraft or turbine blade.

Any ice can add weight, unbalance a blade and ruin lift, causing serious problems for aircraft and turbines alike. When ice forms on propellers or near engine inlets it may be ingested, potentially causing catastrophic failures.

More about protection of aircraft here.

Over time, even tiny ice particles can create cracks in blades, weakening seals and negatively affecting aerodynamics.

And when humidity and saline get together – in any offshore wind site, for example – you’ve got a confounding combination for turbine blades and all of their electronic equipment.

Salty Situation: Icing May Be Worse for Offshore Wind Farms

10 second science review: Salt-plus-ice is more corrosive and potentially damaging than either alone, but it occurs less often, since salt water freezes at a lower temperature than non-salinized water. Because of its saline content, ocean water freezes at a lower temperature (around 28 degrees Fahrenheit) than freshwater. But, when saltwater freezes, the ice contains little salt, since only the water freezes.

You may recall from your high school chemistry class that sea spray water droplets are much bigger than freshwater, however – making offshore ice somewhat worse than freshwater ice.

How are US Offshore wind farm sites selected, and where are they being developed?

Energy attorney Kevin Ewing explains.

Unfortunately, a lot more science is required when assessing the combined risks of lightning and icing, and understanding how to reduce the interactions between LPS and deicing systems.

Deicing and LPS: It’s Complicated

As noted above, existing de-icing solutions may be mechanical, coating, or heating-based systems. And how they interact with lightning protection systems (LPS) is quickly becoming more important. In case you missed it: the high Arctic region saw a statistically huge jump in lightning strikes in 2021. (An article in The Guardian drew much of its data on lightning activity from Vaisala’s annual report.)

Image from Vaisala’s Total lightning statistics 2021 annual report

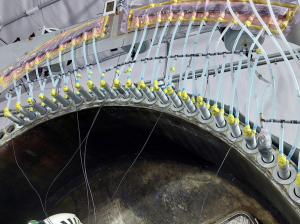

Mechanical deicing removes ice by destroying it, most commonly with ultrasonic waves that work with centrifugal force. This is effective, but it may damage blades.

Heating can also damage blades. While using electric heating with copper coil or carbon fiber net (CFN) is fairly efficient, there’s an increased risk of lightning damage.

Because heating often results in uneven temperatures on the blade surface, and therefor incomplete deicing of the surface, the blade may become imbalanced.

When using the newer method of embedding CFN on the inside of the blade and heating it with an AC power source, the blades are more evenly heated and deicing is more complete. However, the lightning risks are pretty clear.

When lightning strikes at the air terminal of the lightning protection system (LPS) on the blades, and the primary lightning current flows through the down-conductor (inside the blades), the air channel between the electric-heating system and the down-conductor may be broken down and the high voltage potential can generate an arc.

In that case, the arc’s high temperature would damage the blade and most likely, a (smaller) current would enter the electrical heating system and cause additional damage, possibly even a fire.

Embedded CFN heating systems are still new in commercial installations and are improving rapidly.

Icing can affect wind turbines, even in warm climates, as Weather Guard Tech CEO Allen Hall noted in the Forbes article, “The 13,000 Wind Turbines In Texas Can Be Winterized, But Should They?” To discuss your wind turbine performance issues, schedule a consultation today.

What Does the Future Hold for Wind Turbine LPS in Cold Climates?

The Numerical Study of Lightning Protection of Wind Turbine Blade with De-Icing Electrical Heating System, published by the Multidisciplinary Digital Publishing Institute, explains in more detail how a CFN deicing method can affect lightning discharge.

Even newer hybrid systems, such as some that capture solar energy and use it to power deicing systems, may be nearing prototype stage. Research into these photothermal trap methods for deicing is ongoing at MIT and other universities around the world.

Stay up to date with wind technology

No Frozen Wind Turbine Blades Here

If you’re looking for an example of wind’s viability as a power source in extreme climates, consider the Ross Island Wind Farm in New Zealand. RIWF was designed to provide 100% of the energy of NZ’s Scott Base and a portion of the power the US’s McMurdo station.

Thanks to favorable environmental conditions in the Artic (strong winds year-round), RIWF and other wind farms in cold climates have provided plenty of data and helped develop technologies to overcome the harsh environment for many years. As commercialization in the US of onshore and offshore wind farms has increased the pace of technology development, data from the Artic – as well as research conducted in Iowa State University labs – provides the scientific basis we need to improve wind turbine deicing systems efficiency and cost-effectiveness.

We gratefully acknowledge Dr. Hu’s work in aerodynamics and wind turbine deicing and appreciate his joining us for this discussion on the Uptime podcast. His latest book, Wind Turbine Icing Physics and Anti-/De-Icing Technology (Wind Energy Engineering), will publish in June 2022

More Research on Wind Turbine Deicing from Iowa State University

Dr. Hui Hu has been leading research on the most practical ways to avoid ice damage to wind turbines for many years. He is currently the Director of the Advanced Flow Diagnostics and Experimental Aerodynamics Laboratory and of the Aircraft Icing Physics and Anti-/De-icing Technology Laboratory at Iowa State University. Below are some links to some of Dr. Hu’s research.

Dr. Hu’s department and lab was instrumental in developing LEWICE, which, like FENSAP-ICE is a mathematical method used to model ice shapes (rime, glaze and mixed).

Dr. Hu explained the science behind frozen wind turbines in a 2021 article in The Conversation. Read it here.

.

Ice can damage a wind turbine in different ways. Ice adds weight to turbine blades, which reduces power production. Because ice also affects blade aerodynamics, it affects efficiency. It can also create an imbalance in the blades that can cause the turbine to stop, create cracks in the blade or possibly even cause a blade to break off. Dr. Hui Hu has conducted research on the most practical ways to avoid ice damage to wind turbines. He currently runs the Aircraft Icing Physics and Anti-/De-icing Technology Laboratory at Iowa State University.