Listen to the entire interview on Spotify

With wind turbines growing larger and bolts getting bigger, the industry needs smarter ways to handle critical bolted connections. IntoMachines has developed unique tools that make bolt tensioning faster, safer, and much less expensive. – Allen Hall, CEO, Weather Guard Lightning Tech

As wind turbines grow taller and more powerful, the hardware that holds them together—those critical bolted joints—have also scaled up. As a result, the technicians and engineers who assemble, tension, and maintain those structural connections. Traditional bolt tensioning for wind turbines is physically grueling, time-consuming, and – most problematic from an operational standpoint – it’s often inconsistent. But a new wave of intelligent, automated tools from IntoMachines is providing significant improvements.

We invited IntoMachines co-founder Martin Kristelijn to explain how team is reshaping bolt tensioning by addressing its core challenges: efficiency, safety, and quality. This is a recap of our interview with him on the Uptime Wind Energy Podcast,.

Bolt Tensioning for Wind Turbines – From Manual to Modern Tools

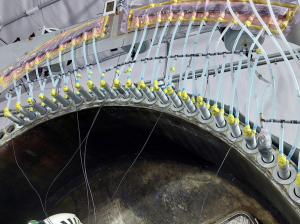

Today’s wind turbines contain more than 600 critical bolted connections, each requiring precise preload for long-term structural integrity. Manual hydraulic tensioning tools, while accurate, are heavy—some weighing over 50 kg (110 lbs)—and they must be moved from bolt to bolt, often under difficult field conditions.

Technicians report arm strain, repetitive stress injuries, and fatigue after handling thousands of bolts, leading to decreased productivity and increased risk of errors. And, it’s a real pain. As Kristelijin said – with what was a bit of understatement, “after a thousand bolts, your arm really starts to hurt.”

The Shift to Tensioning—and Why It Matters

Increasingly, bolt tensioning is preferred over torqueing. Tensioning directly applies axial load, bypassing the unpredictable friction coefficients associated with torque methods. “You apply hydraulic pressure, stretch the bolt, tighten the nut, and release,” Kristelijn explains. “It gives you exact preload every time.”

The downside? Speed and ergonomics. That’s where IntoMachines comes in.

The Solution: Smart, Weightless, and Fast

IntoMachines has engineered a Quantum Smart Tensioning System that integrates:

- A motorized tensioner (developed with partner TensionPro)

- A compact lift trolley that renders the tool weightless

- User-friendly software that enables operation with minimal training

The trolley is designed for mobility inside turbine towers: it’s low-profile enough to slide under staircases, and rugged enough for harsh environments. A gas spring counterbalances the tool’s weight, eliminating manual lifting. IntoMachines offers a “try-out” of their tools on its website.

The result? Dramatically reduced technician fatigue and faster cycle times.

Bolt Tensioning for Wind Turbines – Tools in Use Today

The Quantum system is already in use across Europe and Asia. With users reporting faster adjustments, less strain on workers, and high-quality, traceable documentation of each bolt tensioned, interest is growing and requests are coming in from US wind sites as well.

Looking Ahead: Autonomous Tensioning

IntoMachines isn’t stopping there. Their next-gen innovation is a robotic crawler capable of autonomously tensioning blade bolts in nacelle production facilities. The same motorized Quantum tensioner is modular enough to integrate into the robot, creating a seamless upgrade path from manual to autonomous operation.

Importantly, the system is built with simplicity and field robustness in mind. As Weather Guard Lightning Tech CCO Joel Saxum notes, “You don’t need a software engineer on site. Technicians can be up and running with a 15-minute intro.”

Learn More About How IntoMachines Improves Bolt Tensioning for Wind Turbines

If you’re responsible for wind turbine assembly or maintenance, IntoMachines’ system could save you thousands of labor hours and significantly improve work conditions.

👉 Visit intomachines.com

📩 Contact: sales@intomachines.com

📲 Follow: IntoMachines on LinkedIn

Listen to the entire interview on Spotify

Subscribe to the Uptime Wind Energy Podcast here. Over a million listeners count on Uptime to keep up with the Wind Energy Industry!